Journal of Peking University(Health Sciences) ›› 2019, Vol. 51 ›› Issue (1): 93-99. doi: 10.19723/j.issn.1671-167X.2019.01.017

Previous Articles Next Articles

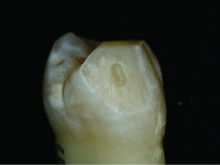

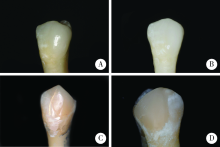

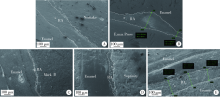

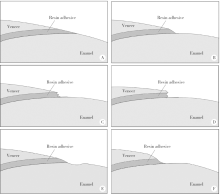

Analysis of edge morphology of partial veneers made by different processing techniques and materials

Rui-jie WANG1,Min LIU1,Dan-yang SONG1,Sui YANG1,Qiao WANG2,Lei WANG1,△( ),Hai-lan FENG1,△(

),Hai-lan FENG1,△( )

)

- 1. Department of Prosthodontics, Beijing 100081, China

2. Dental Laboratory, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

CLC Number:

- R783.3

| [1] |

Gurel G . Porcelain laminate veneers: minimal tooth preparation by design[J]. Dent Clin North Am, 2007,51(2):419-431.

doi: 10.1016/j.cden.2007.03.007 pmid: 17532920 |

| [2] |

刘峰 . 微创和无创瓷贴面修复的适应范围[J]. 口腔颌面修复学杂志, 2016,17(6):321-324.

doi: 10.3969/j.issn.1009-3761.2016.06.001 |

| [3] |

D’Arcangelo C, Vadini M, D’Amario M , et al. Protocol for a new concept of no-prep ultrathin ceramic veneers[J]. J Esthet Restor Dent, 2018,30(3):173-179.

doi: 10.1111/jerd.12351 pmid: 29139209 |

| [4] |

Farias-Neto A, Gomes EM, Sánchez-Ayala A , et al. Esthetic rehabilitation of the smile with no-prep porcelain laminates and partial veneers[J]. Case Rep Dent, 2015,2015:452765.

doi: 10.1155/2015/452765 pmid: 4628695 |

| [5] |

Vadini M, D’Amario M, De Angelis F , et al. No-prep rehabilitation of fractured maxillary incisors with partial veneers[J]. J Esthet Restor Dent, 2016,28(6):351-358.

doi: 10.1111/jerd.12229 pmid: 27354182 |

| [6] | 周玉 . 陶瓷材料学[M]. 2版.北京: 科学出版社, 2004. |

| [7] |

Vanlioglu BA, Kulak-Ozkan Y . Minimally invasive veneers: current state of the art[J]. Clin Cosmet Investig Dent, 2014(6):101-107.

doi: 10.2147/CCIDE.S53209 pmid: 25506248 |

| [8] |

刘峰, 师晓蕊, 李祎 , 等. 微创全瓷贴面修复临床应用初探[J]. 中华口腔医学杂志, 2012,47(10):614-617.

doi: 10.3760/cma.j.issn.1002-0098.2012.10.009 |

| [9] |

Gresnigt M, Ozcan M . Esthetic rehabilitation of anterior teeth with porcelain laminates and sectional veneers[J]. J Can Dent Assoc, 2011,77:b143.

doi: 10.5167/uzh-58750 pmid: 22067068 |

| [10] |

Sulik WD, Plekavich EJ . Surface finishing of dental porcelain[J]. J Prosthet Dent, 1981,46(2):217-221.

doi: 10.1016/0022-3913(81)90312-7 pmid: 6944487 |

| [11] |

Stappert CF, Ozden U, Gerds T , et al. Longevity and failure load of ceramic veneers with different preparation designs after exposure to masticatory simulation[J]. J Prosthet Dent, 2005,94(2):132-139.

doi: 10.1016/j.prosdent.2005.05.023 pmid: 16046967 |

| [12] |

Magne P, Versluis A, Douglas WH . Effect of luting composite shrinkage and thermal loads on the stress distribution in porcelain laminate veneers[J]. J Prosthet Dent, 1999,81(3):335-344.

doi: 10.1016/S0022-3913(99)70278-7 |

| [13] |

Ghaffari T, Hamedi-Rad F, Fakhrzadeh V . Marginal adaptation of Spinell InCeram and feldspathic porcelain laminate veneers[J]. Dent Res J (Isfahan), 2016,13(3):239-244.

doi: 10.4103/1735-3327.182183 pmid: 4878208 |

| [14] |

Karagozoglu I, Toksavul S, Toman M . 3D quantification of clinical marginal and internal gap of porcelain laminate veneers with minimal and without tooth preparation and 2-year clinical evaluation[J]. Quintessence Int, 2016,47(6):461-471.

doi: 10.3290/j.qi.a35700 pmid: 26949761 |

| [15] |

Zhi L, Bortolotto T, Krejci I . Comparative in vitro wear resistance of CAD/CAM composite resin and ceramic materials[J]. J Prosthet Dent, 2016,115(2):199-202.

doi: 10.1016/j.prosdent.2015.07.011 |

| [16] |

Pfeilschifter M, Preis V, Behr M , et al. Edge strength of CAD/CAM materials[J]. J Dent, 2018,74:95-100.

doi: 10.1016/j.jdent.2018.05.004 pmid: 29777736 |

| [17] |

Ganapathy D, Sathyamoorthy A, Ranganathan H , et al. Effect of resin bonded luting agents influencing marginal discrepancy in all ceramic complete veneer crowns[J]. J Clin Diagn Res, 2016,10(12):C67-C70.

doi: 10.1111/crj.12187 pmid: 25043510 |

| [1] | Hao LUO,Fu-cong TIAN,Xiao-yan WANG. Surface roughness, gloss and sequential polishing times of various chairside computer aided design/manufacturing restorative materials [J]. Journal of Peking University (Health Sciences), 2022, 54(3): 565-571. |

| [2] | Ling WEI,Dong ZOU,Hu CHEN,Shao-xia PAN,Yu-chun SUN,Yong-sheng ZHOU. Evaluation of clinical efficacy of a kind of digital complete denture [J]. Journal of Peking University (Health Sciences), 2020, 52(4): 762-770. |

| [3] | Yu-chun SUN,Yong WANG,Ke-hui DENG,Hu CHEN,Wei-wei LI,Yi-jiao ZHAO,Shao-xia PAN,Hong-qiang YE,Yong-sheng ZHOU. Independent innovation research of functionally suitable denture digital system [J]. Journal of Peking University (Health Sciences), 2020, 52(2): 390-394. |

| [4] | ZHOU Tuan-feng, WANG Xin-zhi . Clinical observation of the restoration of computer aided designed and manufactured one-piece zirconia posts and cores: a 5-year prospective follow-up study [J]. Journal of Peking University(Health Sciences), 2018, 50(4): 680-684. |

| [5] | CHEN Hu, ZHAO Tian, WANG Yong, SUN Yu-chun. Computer aided design and 3-dimensional printing for the production of custom trays of maxillary edentulous jaws based on 3-dimensional scan of primary impression [J]. Journal of Peking University(Health Sciences), 2016, 48(5): 900-904. |

|

||