Journal of Peking University (Health Sciences) ›› 2022, Vol. 54 ›› Issue (3): 565-571. doi: 10.19723/j.issn.1671-167X.2022.03.025

Previous Articles Next Articles

Surface roughness, gloss and sequential polishing times of various chairside computer aided design/manufacturing restorative materials

Hao LUO1,Fu-cong TIAN2,Xiao-yan WANG1,*( )

)

- 1. Department of Cariology and Endodontology, Peking University School and Hospital of Stomatology & National Center of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Research Center of Oral Biomaterials and Digital Medical Devices & Beijing Key Laboratory of Digital Stomatology & NHC Research Center of Engi-neering and Technology for Computerized Dentistry & NMPA Key Laboratory for Dental Materials, Beijing 100081, China

2. Department of Endodontics, Dental College of Georgia at Augusta University, Augusta GA30912, USA

CLC Number:

- R783.1

| 1 |

Blatz MB , Conejo J . The current state of chairside digital dentistry and materials[J]. Dent Clin North AM, 2019, 63 (2): 175- 197.

doi: 10.1016/j.cden.2018.11.002 |

| 2 | 刘诗铭, 刘峰. 椅旁修复材料分类和新进展[J]. 口腔医学, 2017, 37 (8): 673- 677. |

| 3 |

Pfefferle R , Luemkemann N , Wiedenmann F , et al. Different polishing methods for zirconia: impact on surface, optical, and mechanical properties[J]. Clin Oral Invest, 2020, 24 (1): 395- 403.

doi: 10.1007/s00784-019-02953-6 |

| 4 |

Kilinc H , Turgut S . Optical behaviors of esthetic CAD/CAM restorations after different surface finishing and polishing procedures and UV aging: an in vitro study[J]. J Prosthet Dent, 2018, 120 (1): 107- 113.

doi: 10.1016/j.prosdent.2017.09.019 |

| 5 |

Yuan CY , Wang XY , Gao XJ , et al. Effects of surface properties of polymer-based restorative materials on early adhesion of strep-tococcus mutans in vitro[J]. J Dent, 2016, 54, 33- 40.

doi: 10.1016/j.jdent.2016.07.010 |

| 6 | 王桃, 郭震威, 郭慧晶, 等. 不同抛光工具对陶瓷抛光效果的比较研究[J]. 华西口腔医学杂志, 2017, 35 (2): 171- 175. |

| 7 |

Flury S , Lussi A , Zimmerli B . Performance of different polishing techniques for direct CAD/CAM ceramic restorations[J]. Oper Dent, 2010, 35 (4): 470- 481.

doi: 10.2341/09-373-L |

| 8 |

Kaizer MR , de Oliveira-Ogliari A , Cenci MS , et al. Do nanofill or submicron compo-sites show improved smoothness and gloss? A systematic review of in vitro studies[J]. Dent Mater, 2014, 30 (4): e41- e78.

doi: 10.1016/j.dental.2014.01.001 |

| 9 | Jung M , Otte A , Klimek J . Is surface roughness of resin compo-sites affected by operator′ s performance?[J]. Am J Dent, 2008, 21 (1): 3- 6. |

| 10 |

Jones CS , Billington RW , Pearson GJ . Laboratory study of the loads, speeds and times to finish and polish direct restorative materials[J]. J Oral Rehabil, 2005, 32 (9): 686- 692.

doi: 10.1111/j.1365-2842.2005.01487.x |

| 11 |

Amaya-Pajares SP , Ritter AV , Resendiz CV , et al. Effect of finishing and polishing on the surface roughness of four ceramic materials after occlusal adjustment[J]. J Esthet Restor Dent, 2016, 28 (6): 382- 396.

doi: 10.1111/jerd.12222 |

| 12 | Jones CS , Billington RW , Pearson GJ . Interoperator variability during polishing[J]. Quintessence Int, 2006, 37 (3): 183- 190. |

| 13 |

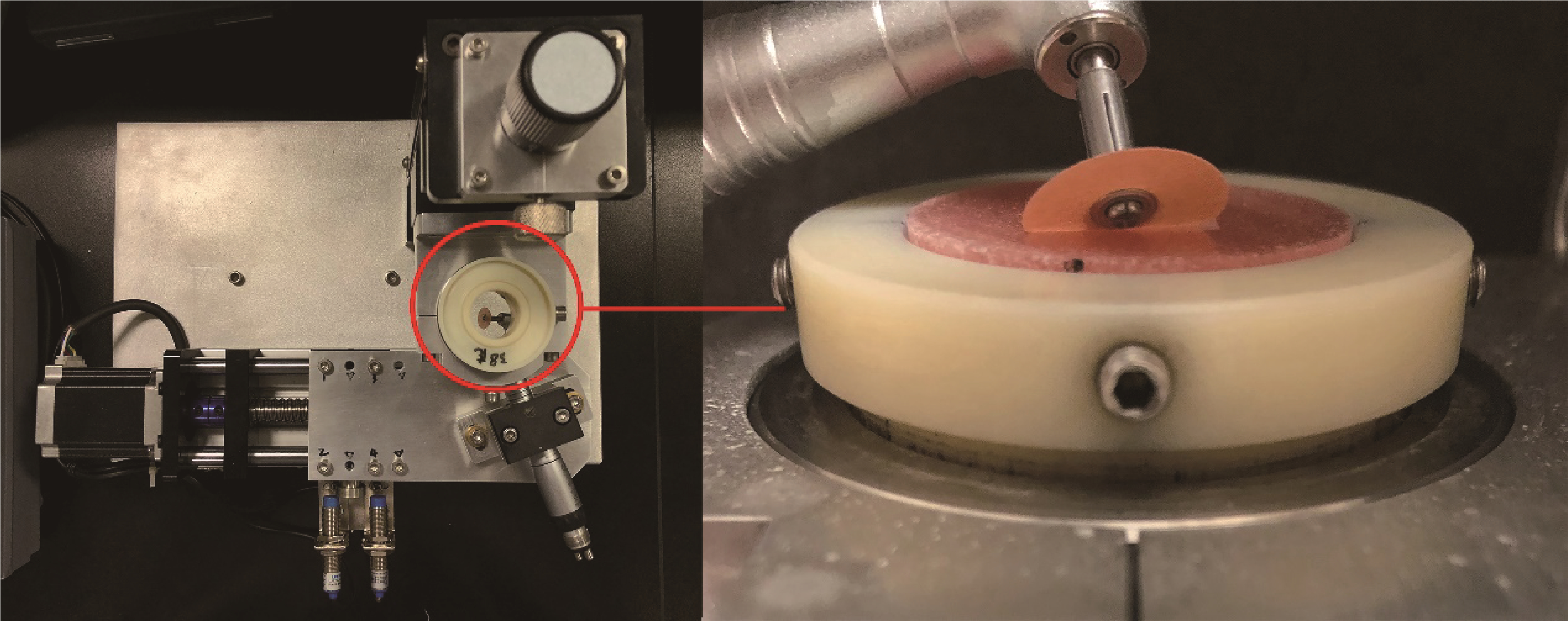

Heintze SD , Reinhardt M , Muller F , et al. Press-on force during polishing of resin composite restorations[J]. Dent Mater, 2019, 35 (6): 937- 944.

doi: 10.1016/j.dental.2019.03.009 |

| 14 |

Vichi A , Fonzar RF , Goracci C , et al. Effect of finishing and po-lishing on roughness and gloss of lithium disilicate and lithium silicate zirconia reinforced glass ceramic for CAD/CAM systems[J]. Oper Dent, 2018, 43 (1): 90- 100.

doi: 10.2341/16-381-L |

| 15 |

Wilder AD Jr. , Swift EJ Jr. , May KN Jr. , et al. Effect of finishing technique on the microleakage and surface texture of resin-modified glass ionomer restorative materials[J]. J Dent, 2000, 28 (5): 367- 373.

doi: 10.1016/S0300-5712(99)00075-5 |

| 16 |

Flury S , Diebold E , Peutzfeldt A , et al. Effect of artificial toothbrushing and water storage on the surface roughness and micromechanical properties of tooth-colored CAD-CAM materials[J]. J Prosthet Dent, 2017, 117 (6): 767- 774.

doi: 10.1016/j.prosdent.2016.08.034 |

| 17 |

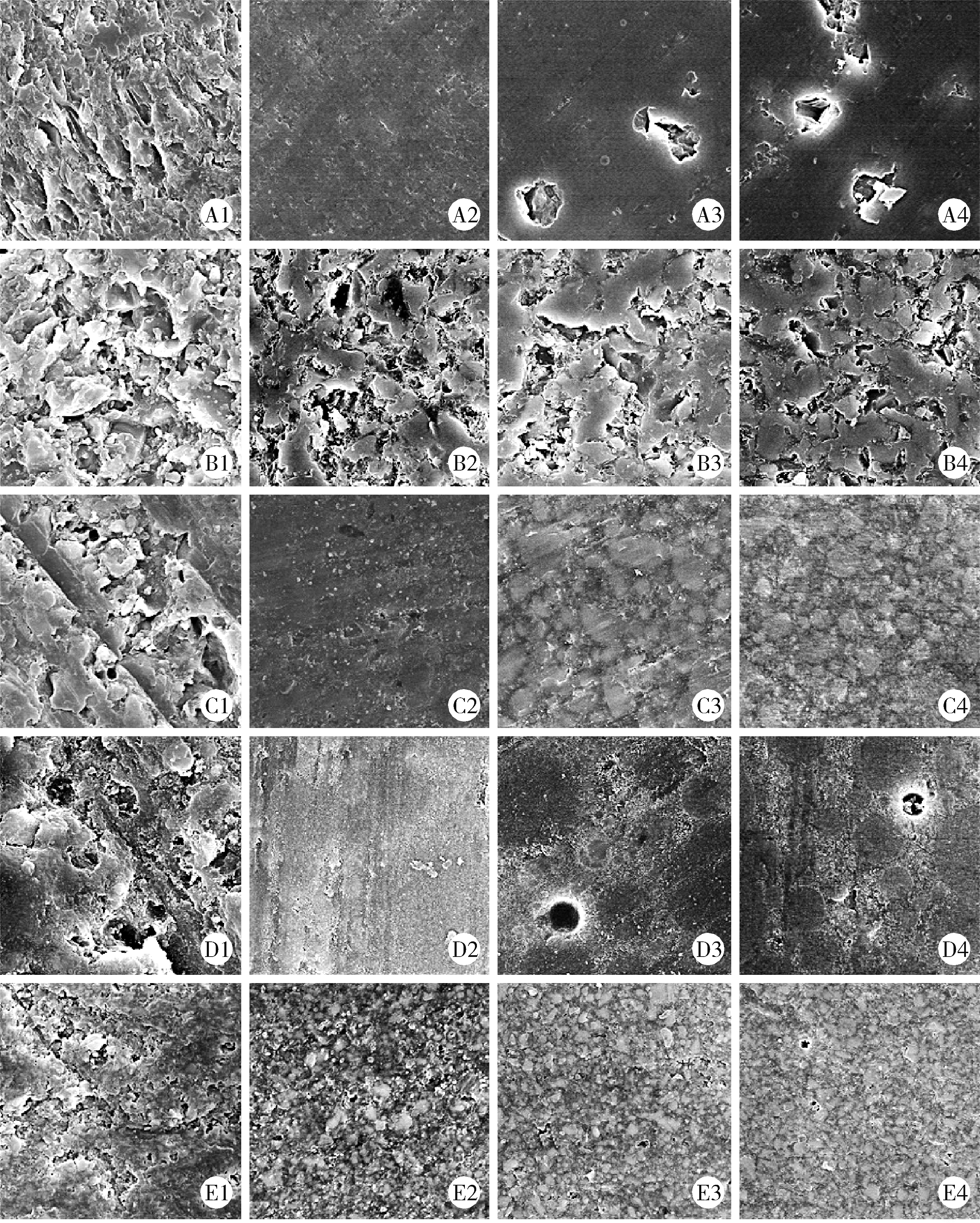

Heintze SD , Forjanic M , Rousson V . Surface roughness and gloss of dental materials as a function of force and polishing time in vitro[J]. Dent Mater, 2006, 22 (2): 146- 165.

doi: 10.1016/j.dental.2005.04.013 |

| 18 |

Markovic L , Jordan RA , Lakota N , et al. Micromorphology of Enamel Surface After Vital Tooth Bleaching[J]. J Endodont, 2007, 33 (5): 607- 610.

doi: 10.1016/j.joen.2007.01.011 |

| 19 |

Bollen CML , Lambrechts P , Quirynen M . Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature[J]. Dent Mater, 1997, 13 (4): 258- 269.

doi: 10.1016/S0109-5641(97)80038-3 |

| 20 |

Mörmmann WH , Stawarczyk B , Ender A , et al. Wear characteristics of current aesthetic dental restorative CAD/CAM materials: two-body wear, gloss retention, roughness and Martens hardness[J]. J Mech Behav Biomed, 2013, 20, 113- 125.

doi: 10.1016/j.jmbbm.2013.01.003 |

| 21 |

Song XF , Yin L . Induced damage zone in micro-fine dental fini-shing of a feldspathic porcelain[J]. Med Eng Phys, 2010, 32 (5): 417- 422.

doi: 10.1016/j.medengphy.2010.04.007 |

| 22 | 徐通, 高平, 魏茜茜, 等. 复合树脂的研究进展[J]. 口腔医学, 2017, 37 (11): 1053- 1056. |

| 23 | 佟舒妍, 吴音, 司文捷. 新型口腔树脂陶瓷复合材料光泽度与粗糙度的研究[J]. 稀有金属材料与工程, 2015, 44, 718- 722. |

| 24 |

Alexander-Katz R , Barrera RG . Surface correlation effects on gloss[J]. J Polym Sci Pol Phys, 1998, 36 (8): 1321- 1334.

doi: 10.1002/(SICI)1099-0488(199806)36:8<1321::AID-POLB7>3.0.CO;2-U |

| 25 |

da Costa JB , Ferracane J , Paravina RD , et al. The effect of different polishing systems on surface roughness and gloss of various resin composites[J]. J Esthet Restor Dent, 2007, 19 (4): 214- 224.

doi: 10.1111/j.1708-8240.2007.00104.x |

| 26 |

Salgado VE , Cavalcante LM , Moraes RR , et al. Degradation of optical and surface properties of resin-based composites with distinct nanoparticle sizes but equivalent surface area[J]. J Dent, 2017, 59, 48- 53.

doi: 10.1016/j.jdent.2017.02.008 |

| [1] | Ling WEI,Dong ZOU,Hu CHEN,Shao-xia PAN,Yu-chun SUN,Yong-sheng ZHOU. Evaluation of clinical efficacy of a kind of digital complete denture [J]. Journal of Peking University (Health Sciences), 2020, 52(4): 762-770. |

| [2] | Jing-ying HU,Li LI,Qian-mei ZHOU,Rui-yu DING,Ran SHANG,Wei BAI. Influence of different mixing pads on physical and mechanical properties of glass ionomer cement [J]. Journal of Peking University(Health Sciences), 2019, 51(5): 964-967. |

| [3] | ZHANG Hao-yu, JIANG Ting, CHENG Ming-xuan, ZHANG Yu-wei. Wear intensity and surface roughness of microhybrid composite and ceramic occlusal veneers on premolars after the thermocycling and cyclic mechanical loading tests [J]. Journal of Peking University(Health Sciences), 2018, 50(1): 73-77. |

|

||