Journal of Peking University (Health Sciences) ›› 2021, Vol. 53 ›› Issue (2): 406-412. doi: 10.19723/j.issn.1671-167X.2021.02.029

Previous Articles Next Articles

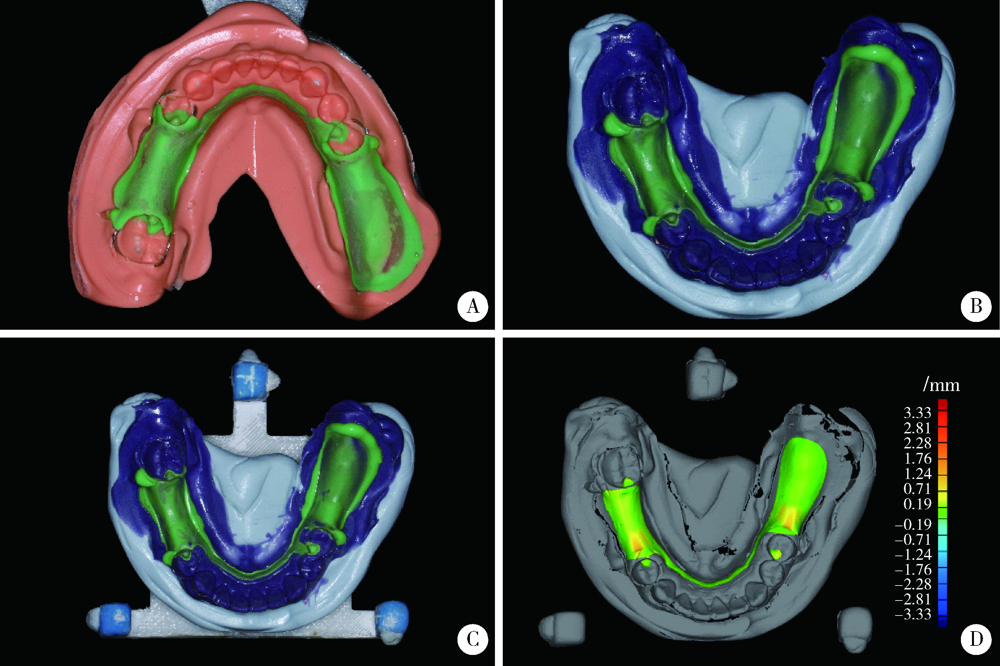

Evaluation of methods for fitness of removable partial denture

YOON Jung-min1,WANG Zi-xuan1,CHAN Chon-kai1,SUN Yu-chun2,LIU Yun-song1,YE Hong-qiang1,Δ( ),ZHOU Yong-sheng1,Δ(

),ZHOU Yong-sheng1,Δ( )

)

- 1. Department of Prosthodontics, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

2. Center for Digital Dentistry, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

CLC Number:

- R783.4

| [1] | 冯海兰. 口腔修复学[M]. 2版. 北京: 北京大学医学出版社, 2013: 135-136. |

| [2] | 刘一帆, 王伟娜, 于海, 等. 选择性激光熔覆(SLM)钛合金可摘局部义齿支架的适合性研究[J]. 实用口腔医学杂志, 2017,33(3):302-305. |

| [3] |

Keltjens HM, Mulder J, Kayser AF, et al. Fit of direct retainers in removable partial dentures after 8 years of use[J]. J Oral Rehabil, 1997,24(2):138-142.

pmid: 9061623 |

| [4] | 吴琳, 吕培军, 王勇, 等. 可摘局部义齿支架铸型的计算机辅助设计与制作[J]. 中华口腔医学杂志, 2006,41(7):432-435. |

| [5] |

Frank RP, Brudvik JS, Leroux B, et al. Relationship between the standards of removable partial denture construction, clinical acceptability, and patient satisfaction[J]. J Prosthet Dent, 2000,83(5):521-527.

pmid: 10793382 |

| [6] | Hu F, Pei Z, Wen Y. Using intraoral scanning technology for three-dimensional printing of kennedy class Ⅰ removable partial denture metal framework: a clinical report[J]. J Prosthodont, 2019,28(2):473-476. |

| [7] |

Dunham D, Brudvik JS, Morris WJ, et al. A clinical investigation of the fit of removable partial dental prosjournal clasp assemblies[J]. J Prosthet Dent, 2006,95(4):323-326.

pmid: 16616131 |

| [8] |

Lee JW, Park JM, Park EJ, et al. Accuracy of a digital removable partial denture fabricated by casting a rapid prototyped pattern: A clinical study[J]. J Prosthet Dent, 2017,118(4):468-474.

pmid: 28389024 |

| [9] |

Torii M, Nakata T, Takahashi K, et al. Fitness and retentive force of cobalt-chromium alloy clasps fabricated with repeated laser sintering and milling[J]. J Prosthodont Res, 2018,62(3):342-346.

pmid: 29428170 |

| [10] |

Viswambaran M, Sundaram RK. Effect of storage time and framework design on the accuracy of maxillary cobalt-chromium cast removable partial dentures[J]. Contemp Clin Dent, 2015,6(4):471-476.

pmid: 26681850 |

| [11] |

Ye H, Ning J, Li M, et al. Preliminary clinical application of removable partial denture frameworks fabricated using computer-aided design and rapid prototyping techniques[J]. Int J Prosthodont, 2017,30(4):348-353.

pmid: 28697204 |

| [12] |

Arnold C, Hey J, Schweyen R, et al. Accuracy of CAD-CAM-fabricated removable partial dentures[J]. J Prosthet Dent, 2018,119(4):586-592.

pmid: 28709674 |

| [13] |

Lee WS, Lee DH, Lee KB. Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system[J]. J Adv Prosthodont, 2017,9(4):265-270.

pmid: 28874993 |

| [14] | Kim DY, Kim JH, Kim HY, et al. Comparison and evaluation of marginal and internal gaps in cobalt-chromium alloy copings fabricated using subtractive and additive manufacturing[J]. J Pros-thodont Res, 2018,62(1):56-64. |

| [15] |

Ye H, Li X, Wang G, et al. A Novel computer-aided design/computer-assisted manufacture method for one-piece removable partial denture and evaluation of fit[J]. Int J Prosthodont, 2018,31(2):149-151.

pmid: 29448267 |

| [16] |

Groten M, Axmann D, Probster L, et al. Determination of the minimum number of marginal gap measurements required for practical in vitro testing[J]. J Prosthet Dent, 2000,83(1):40-49.

pmid: 10633021 |

| [17] |

Liu Y, Ye H, Wang Y, et al. Three-dimensional analysis of internal adaptations of crowns cast from resin patterns fabricated using computer-aided design/computer-assisted manufacturing technologies[J]. Int J Prosthodont, 2018,31(4):386-393.

pmid: 29772034 |

| [18] |

Kim KB, Kim JH, Kim WC, et al. Three-dimensional evaluation of gaps associated with fixed dental prostheses fabricated with new technologies[J]. J Prosthet Dent, 2014,112(6):1432-1436.

pmid: 25218032 |

| [19] | 李欣欣, 柳玉树, 孙玉春, 等. 计算机辅助设计与制作一体化聚醚醚酮可摘局部义齿不同形态组件的适合性评价[J]. 北京大学学报(医学版), 2019,51(2):335-339 |

| [20] |

Anadioti E, Aquilino SA, Gratton DG, et al. 3D and 2D marginal fit of pressed and CAD/CAM lithium disilicate crowns made from digital and conventional impressions[J]. J Prosthodont, 2014,23(8):610-617.

pmid: 24995593 |

| [1] | Weimin LI,Zufeiya TUERDI. Comparative research on the relationship between body mass index and physical fitness index among the Uygur, Kazakh and Han ethnic college students [J]. Journal of Peking University (Health Sciences), 2024, 56(3): 411-417. |

| [2] | Huameng TANG,Dianqi YUAN,Mingxing WANG,Hanbing YANG,Chao GUO. Sequential mediating role of digital participation and health lifestyle in the relationship between socioeconomic status and depression of older adults [J]. Journal of Peking University (Health Sciences), 2024, 56(2): 230-238. |

| [3] | Andong CAI,Xiaoxia WANG,Wenjuan ZHOU,Zhonghao LIU. Comparison of the virtual surgical planning position of maxilla and condyle with the postoperative real position in patients with mandibular protrusion [J]. Journal of Peking University (Health Sciences), 2024, 56(1): 74-80. |

| [4] | Tuan-feng ZHOU,Xue YANG,Rui-jie WANG,Ming-xuan CHENG,Hua ZHANG,Jin-qi WEI. A clinical application study of digital manufacturing simple intraoral Gothic arch-tracing device in determining the centric relation of complete dentures [J]. Journal of Peking University (Health Sciences), 2023, 55(1): 101-107. |

| [5] | SUN Yu-chun,GUO Yu-qing,CHEN Hu,DENG Ke-hui,LI Wei-wei. Independent innovation research, development and transformation of precise bionic repair technology for oral prosthesis [J]. Journal of Peking University (Health Sciences), 2022, 54(1): 7-12. |

| [6] | Yuan LI,Hong LIN,Tie-jun ZHANG. Comparative study on radio-opacity of dental composite resin materials’determination using film imaging and digital imaging [J]. Journal of Peking University (Health Sciences), 2021, 53(5): 995-1001. |

| [7] | LI Zheng,LIU Yu-shu,WANG Shi-min,ZHANG Rui,JIA Lu,YE Hong-qiang,HU Wen-jie,ZHAO Wen-yan,LIU Yun-song,ZHOU Yong-sheng. Application of biocopy function of temporary crown occlusal morphology in patients with severe attrition [J]. Journal of Peking University (Health Sciences), 2021, 53(1): 62-68. |

| [8] | Yi SONG,Dong-mei LUO,Pei-jin HU,Xiao-jin YAN,Jing-shu ZHANG,Yuan-ting LEI,Bing ZHANG,Jun MA. Trends of prevalence of excellent health status and physical fitness among Chinese Han students aged 13 to 18 years from 1985 to 2014 [J]. Journal of Peking University (Health Sciences), 2020, 52(2): 317-322. |

| [9] | Chuan REN,Xiao-yue WU,Wei ZHAO,Li-yuan TAO,Ping LIU,Wei GAO. Protective effect of cardiopulmonary fitness on patients with high risk of atherosclerotic cardiovascular disease [J]. Journal of Peking University(Health Sciences), 2020, 52(1): 152-157. |

| [10] | Yue CAO,Jun-kai CHEN,Ke-hui DENG,Yong WANG,Yu-chun SUN,Yi-jiao ZHAO. Accuracy of three intraoral scans for primary impressions of edentulous jaws [J]. Journal of Peking University(Health Sciences), 2020, 52(1): 129-137. |

| [11] | SONG Yi,LEI Yuan-ting, HU Pei-jin, ZHANG Bing, MA Jun. Situation analysis of physical fitness among Chinese Han students in 2014 [J]. Journal of Peking University(Health Sciences), 2018, 50(3): 436-442. |

| [12] | LI Zheng, LIU Yu-shu, YE Hong-qiang, LIU Yun-song, HU Wen-jie, ZHOU Yong-sheng. Diagnossis and treatment of complicated anterior teeth esthetic defects by combination of whole-process digital esthetic rehabilitation with periodontic surgery [J]. Journal of Peking University(Health Sciences), 2017, 49(1): 71-075. |

| [13] | ZHANG Ming-ming, LIANG Yu-hong, GAO Xue-jun. Comparison of periapical radiography and cone-beam computed tomography in endodontic treated teeth for assessment of periapical lesions [J]. Journal of Peking University(Health Sciences), 2016, 48(3): 539-543. |

| [14] | LI Yuan, ZHENG Gang, LIN Hong. Evaluation method with radiographic image quality indicator for internal defects of dental casting metallic restoration [J]. Journal of Peking University(Health Sciences), 2014, 46(6): 963-968. |

|

||