Journal of Peking University(Health Sciences) ›› 2019, Vol. 51 ›› Issue (1): 111-114. doi: 10.19723/j.issn.1671-167X.2019.01.020

Previous Articles Next Articles

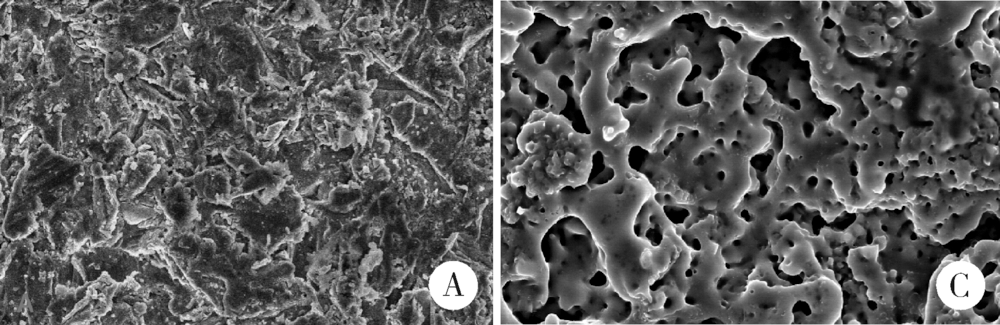

Effects of CAD/CAM titanium alloy surface treatment and resin luting on shear bond strength and durability of composite resin

- 1. Department of Oral Implantology, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

2. Department of Oral Implantology, Beijing Stomatological Hospital, School of Stomatology, Capital Medical University, Beijing 100050, China

CLC Number:

- R783.1

| [1] |

Guo CY, Tang ATH, Matinlinna JP . Insights into surface treatment methods of titanium dental implants[J]. J Adhes Sci Tech-nol, 2012,26(1/2/3):189-205.

doi: 10.1163/016942411X569390 |

| [2] |

Abduo J . Fit of CAD/CAM implant frameworks: a comprehensive review[J]. J Oral Implantlol, 2014,40(6):758-766.

doi: 10.1563/AAID-JOI-D-12-00117.1 pmid: 23009670 |

| [3] |

Molitor P, Barron V, Young T . Surface treatment of titanium for adhesive bonding to polymer composites: a review[J]. Int J Adhes, 2001,21(2):129-136.

doi: 10.1016/S0143-7496(00)00044-0 |

| [4] |

Egoshi T, Taira Y, Soeno K , et al. Effects of sandblasting, H2SO4/HCl etching, and phosphate primer application on bond strength of veneering resin composite to commercially pure titanium grade 4[J]. Dent Mater J, 2013,32(2):219-227.

doi: 10.4012/dmj.2012-261 pmid: 23538756 |

| [5] |

Yang G, Xianyi L, Bai Y , et al. The effects of current density on the phase composition and microstructure properties of micro-arc oxidation coating[J]. J Alloy Compd, 2002,345(1/2):196-200.

doi: 10.1016/S0925-8388(02)00289-X |

| [6] |

Taira Y, Yanagida H, Matsumura H , et al. Adhesive bonding of titanium with a thione-phosphate dual functional primer and self-curing luting agents[J]. Eur J Oral Implantol, 2000,108(5):456-460.

doi: 10.1034/j.1600-0722.2000.108005456.x pmid: 11037763 |

| [7] |

马志玲, 刘杰 . 钛基底表面处理对钛-树脂粘接强度的影响[J]. 国际口腔医学杂志, 2017,44(1):45-49.

doi: 10.7518/gjkq.2017.01.009 |

| [8] |

Darvell BW, Samman N, Luk WK , et al. Contamination of titanium castings by aluminium oxide blasting[J]. J Dent, 1995,23(5):319-322.

doi: 10.1016/0300-5712(94)00003-X pmid: 7560379 |

| [9] |

Ban S, Taniki T, Sato H , et al. Acid etching of titanium for bonding with veneering composite resins[J]. Dent Mater J, 2006,25(2):382.

doi: 10.4012/dmj.25.382 pmid: 16916245 |

| [10] |

Nie X, Leyland A, Matthews A . Deposition of layered bioceramic hydroxyapatite/TiO2, coatings on titanium alloys using a hybrid technique of micro-arc oxidation and electrophoresis[J]. Surf Coat Tech, 2000,125(1/2/3):407-414.

doi: 10.1016/S0257-8972(99)00612-X |

| [11] |

蒋百灵, 张菊梅, 时惠英 . 钛合金微弧氧化膜表面形貌对膜/环氧树脂结合强度的影响[J]. 中国有色金属学报, 2004,14(4):539-542.

doi: 10.3321/j.issn:1004-0609.2004.04.004 |

| [12] |

Tian J, Luo Z, Qi S , et al. Structure and antiwear behavior of micro-arc oxidized coatings on aluminum alloy[J]. Surf Coat Tech, 2002,154(1):1-7.

doi: 10.1016/S0257-8972(01)01671-1 |

| [13] |

De SG, Hennig D, Aggarwal A , et al. The use of MDP-based materials for bonding to zirconia[J]. J Prosthet Dent, 2014,112(4):895-902.

doi: 10.1016/j.prosdent.2014.01.016 pmid: 24767903 |

| [14] |

Lindgren J, Smeds J, Sjögren G . Effect of surface treatments and aging in water on bond strength to zirconia[J]. Oper Dent, 2008,33(6):675-681.

doi: 10.2341/08-12 pmid: 19051861 |

| [1] | Yuan LI,Hong LIN,Tie-jun ZHANG. Comparative study on radio-opacity of dental composite resin materials’determination using film imaging and digital imaging [J]. Journal of Peking University (Health Sciences), 2021, 53(5): 995-1001. |

| [2] | Yang YANG,Ting-ting PU,Li CHEN,Jian-guo TAN. Morphology accuracy evaluation of direct composite occlusal veneer using two types of modified stamp-technique [J]. Journal of Peking University (Health Sciences), 2021, 53(5): 977-982. |

| [3] | MU Hai-li,TIAN Fu-cong,WANG Xiao-yan,GAO Xue-jun. Evaluation of wear property of Giomer and universal composite in vivo [J]. Journal of Peking University (Health Sciences), 2021, 53(1): 120-125. |

| [4] | GUO Hui-ijie, GAO Cheng-zhi,LIN Fei,LIU Wei,YUE Lin. Effects of saliva contamination on bond strength of resin-resin interfaces [J]. Journal of Peking University(Health Sciences), 2017, 49(1): 96-100. |

| [5] | LIN Fei, LIU Wei, YAN Peng, YUE Lin. Microtensile strength of composite-composite bonding: an in vitro study [J]. Journal of Peking University(Health Sciences), 2015, 47(1): 124-128. |

| [6] | CAI Xue, NIE Jie, WANG Zu-Hua, TIAN Hong-Yan, ZHAO Ying, WANG Xiao-Yan. Effects of different cavosurface margins on color matching of the resin composite [J]. Journal of Peking University(Health Sciences), 2015, 47(1): 120-123. |

| [7] | TIAN Fu-cong, WANG Xiao-yan, GAO Xue-jun. Clinical evaluation of a two-step etch-and-rinse adhesive and a one-step self-etch adhesive in non-carious cervical lesion [J]. Journal of Peking University(Health Sciences), 2014, 46(1): 58-61. |

|

||