北京大学学报(医学版) ›› 2023, Vol. 55 ›› Issue (1): 94-100. doi: 10.19723/j.issn.1671-167X.2023.01.014

氧化锆陶瓷表面硅锂喷涂层的摩擦磨损性能

- 北京大学口腔医学院·口腔医院口腔医学数字化研究中心, 口腔修复教研室, 国家口腔医学中心, 国家口腔疾病临床医学研究中心, 口腔生物材料和数字诊疗装备国家工程研究中心, 口腔数字医学北京市重点实验室, 国家卫生健康委口腔医学计算机应用工程技术研究中心, 北京 100081

Research on friction and wear behaviors of silicon-lithium spray coating on zirconia ceramics

Wei-wei LI,Hu CHEN,Yong WANG,Yu-chun SUN*( )

)

- Center of Digital Dentistry, Faculty of Prosthodontics, Peking University School and Hospital of Stomatology & National Center of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Research Center of Oral Biomaterials and Digital Medical Devices & Beijing Key Laboratory of Digital Stomatology & NHC Research Center of Engineering and Technology for Computerized Dentistry, Beijing 100081, China

摘要:

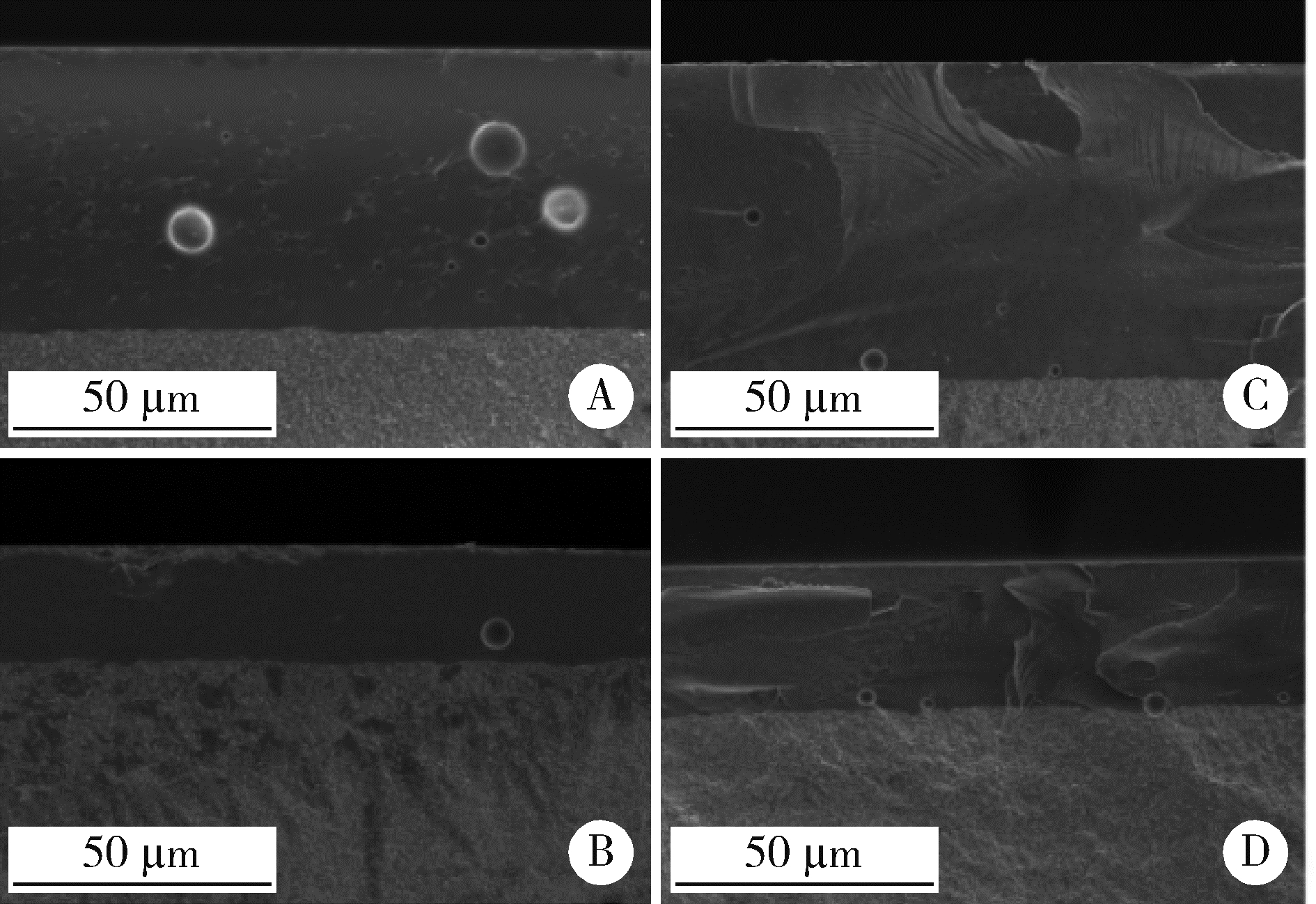

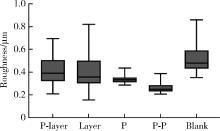

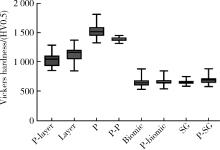

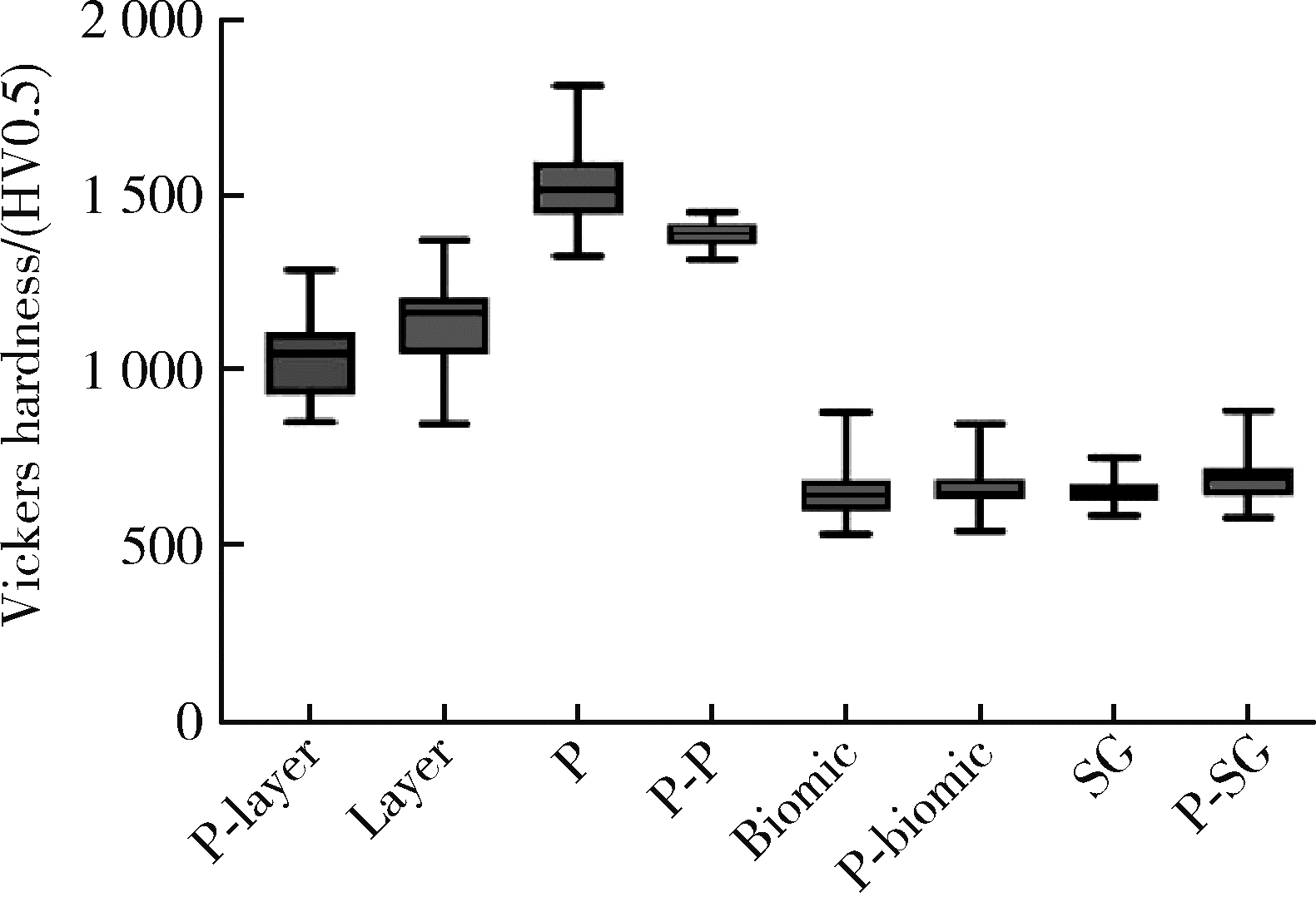

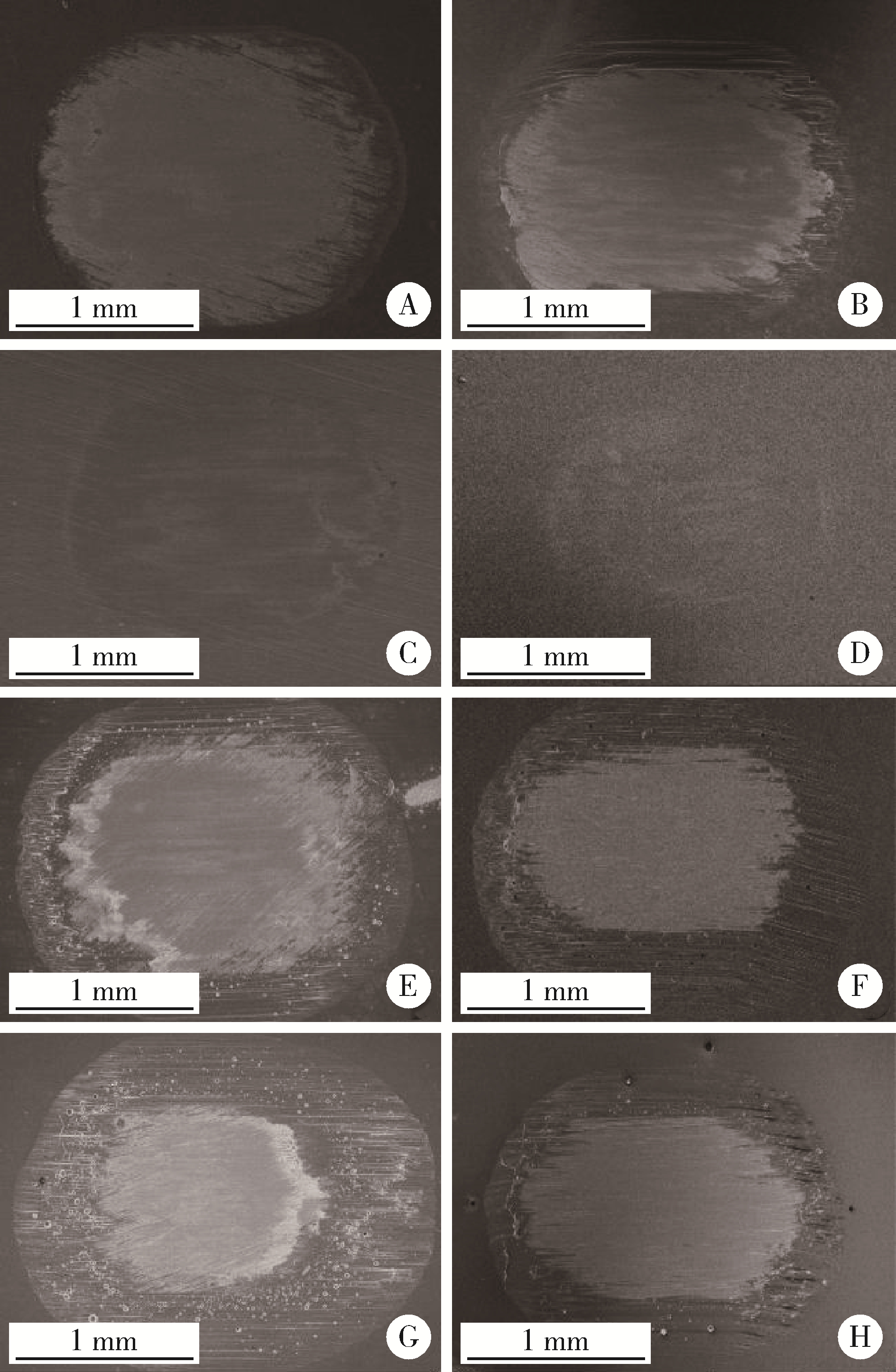

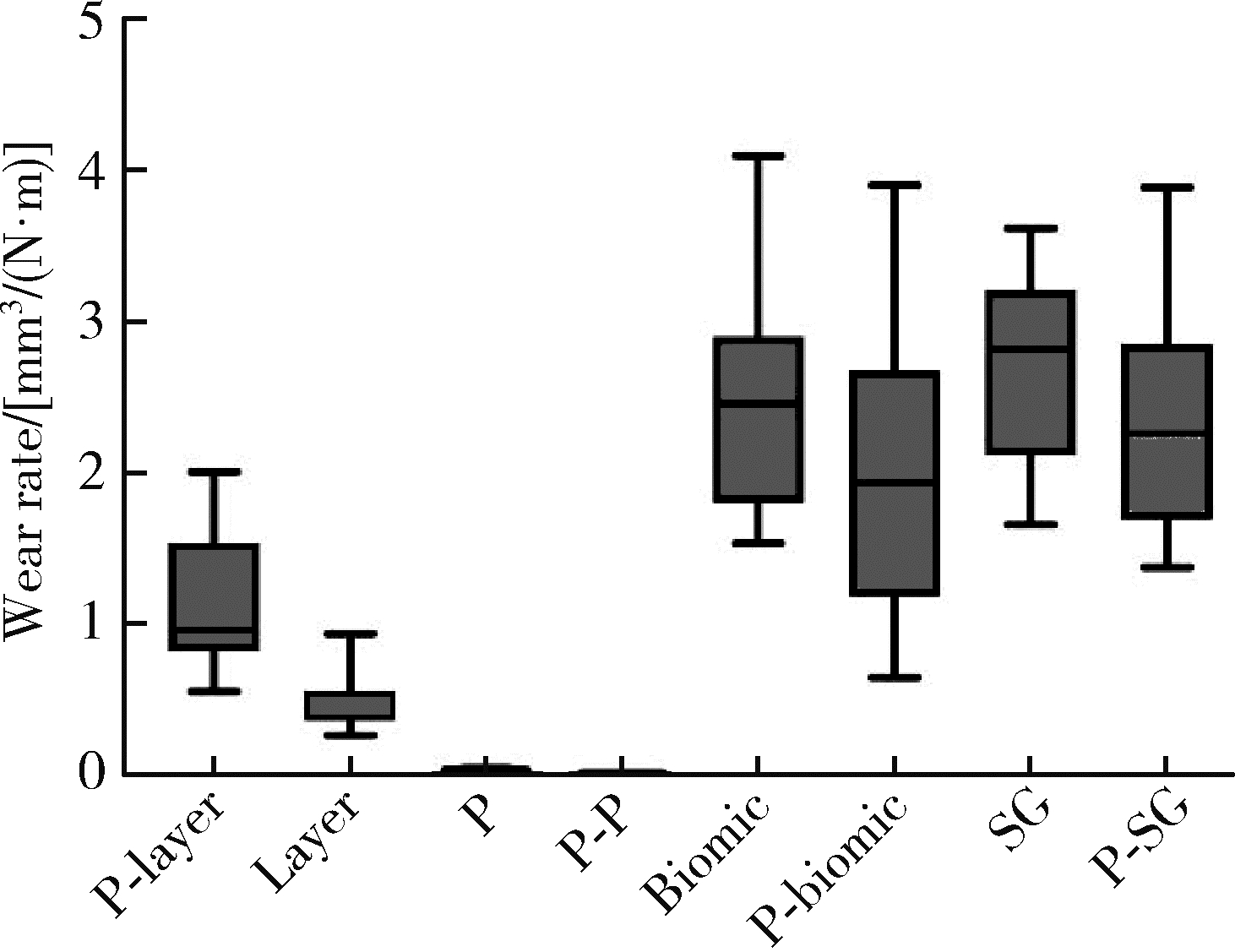

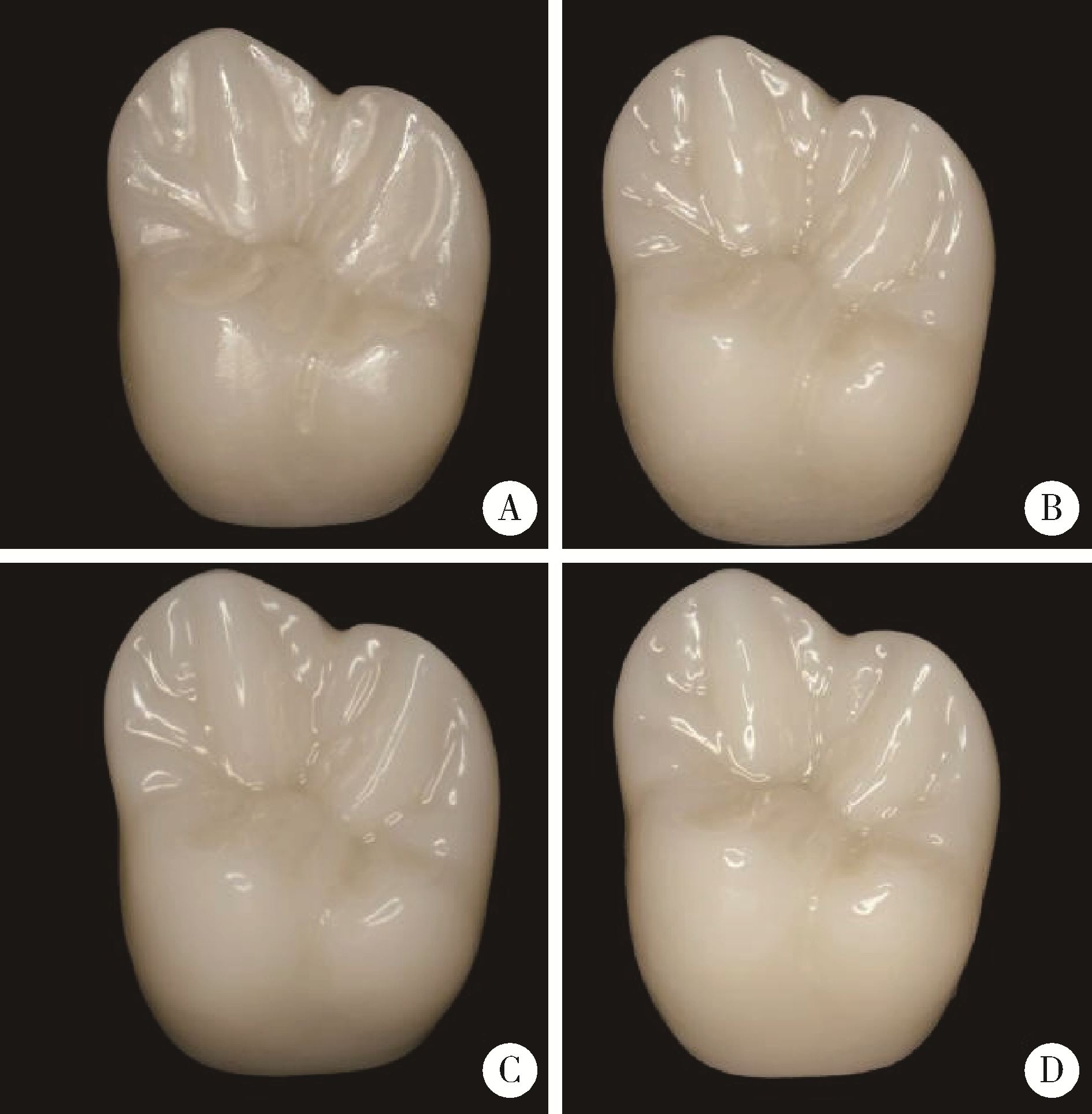

目的: 研究氧化锆陶瓷表面硅锂喷涂层的微观形貌和摩擦磨损性能, 初步评估其美观效果, 为其临床应用提供指导和支持。方法: 将氧化锆陶瓷试样随机分为三组: 涂层组(有2个亚组)、抛光组(有2个亚组)和上釉组(有4个亚组), 每个亚组10个样本。涂层组的两个亚组是对未处理和初步抛光的氧化锆陶瓷表面分别喷涂硅锂喷涂层; 抛光组的两个亚组分别是氧化锆陶瓷表面初步抛光和精细抛光; 上釉组的4个亚组分别是对初步抛光的氧化锆陶瓷表面分别上Biomic釉和Stain/Glaze釉, 未处理的氧化锆陶瓷表面分别上Biomic釉和Stain/Glaze釉。对磨物选用滑石瓷球, 与上述8个亚组的氧化锆陶瓷试样构成摩擦副。应用扫描电镜观测涂层组表面和断面的微观形貌, 测量涂层和釉层的厚度; 应用激光三维形貌显微镜测量涂层组和抛光组表面的线粗糙度; 应用显微硬度计测量各组的维氏硬度。制作氧化锆陶瓷全冠, 初步评价硅锂喷涂层的美观效果。应用口腔咀嚼模拟试验机, 在50 N垂直载荷及人工唾液润滑下进行50 000次咀嚼循环的摩擦磨损试验。应用白光干涉仪, 测量滑石瓷球磨斑的宽度并计算其磨损深度; 测量氧化锆陶瓷试件磨斑的最大深度和体积, 计算磨损率。应用Kruskal-Wallis非参数检验和Dunn's多重检验分析各组的磨损深度, 检验水准α = 0.05。结果: 氧化锆陶瓷表面未处理和初步抛光后形成的两种硅锂喷涂层微观形貌均有突起缺陷, 两者的线粗糙度均大于抛光组。氧化锆陶瓷表面初步抛光后形成的硅锂喷涂层厚度中位数为13.0 μm [四分位距(interquartile range, IQR): 11.6, 17.9], 氧化锆陶瓷表面未处理形成的硅锂喷涂层厚度中位数为4.4 μm(IQR: 4.1, 4.7)。涂层组的维氏硬度值和磨损率均介于抛光组和上釉组之间。对磨的滑石瓷球磨斑深度由大到小依次是上釉组、涂层组和抛光组, 上釉组和抛光组的滑石瓷球磨损深度差异有统计学意义(P < 0.05);各组内随着抛光程度的增加, 滑石瓷球的磨损深度减小。各氧化锆陶瓷试件磨斑的最大深度和体积由大到小依次是上釉组、涂层组和抛光组, 上釉组和抛光组的氧化锆陶瓷试件的磨损深度差异有统计学意义(P < 0.05)。结论: 氧化锆陶瓷表面硅锂喷涂层与抛光处理相比, 增加了氧化锆陶瓷表面美观; 与上釉处理相比, 减少了对磨的滑石瓷球的磨损, 可以作为一种氧化锆陶瓷表面处理的新方法。

中图分类号:

- R781.0

| 1 | 李文晶, 李天舒, 骆雪, 等. 口腔陶瓷修复体调磨后表面处理方法研究进展[J]. 中国实用口腔科杂志, 2018, 11 (1): 57- 60. |

| 2 |

Aljomard Y , Altunok E , Kara H . Enamel wear against monolithic zirconia restorations: A meta-analysis and systematic review of in vitro studies[J]. J Esthet Restor Dent, 2022, 34 (3): 473- 489.

doi: 10.1111/jerd.12823 |

| 3 |

Gou M , Chen H , Kang J , et al. Antagonist enamel wear of tooth-supported monolithic zirconia posterior crowns in vivo: A systema-tic review[J]. J Prosthet Dent, 2019, 121 (4): 598- 603.

doi: 10.1016/j.prosdent.2018.06.005 |

| 4 |

Stawarczyk B , Özcan M , Schmutz F , et al. Two-body wear of monolithic, veneered and glazed zirconia and their corresponding enamel antagonists[J]. Acta Odontol Scand, 2013, 71 (1): 102- 112.

doi: 10.3109/00016357.2011.654248 |

| 5 |

Tang Z , Zhao X , Wang H . Quantitative analysis on the wear of monolithic zirconia crowns on antagonist teeth[J]. BMC Oral Health, 2021, 21 (1): 94.

doi: 10.1186/s12903-021-01452-z |

| 6 |

Amer R , Kürklü D , Kateeb E , et al. Three-body wear potential of dental yttrium-stabilized zirconia ceramic after grinding, polishing, and glazing treatments[J]. J Prosthet Dent, 2014, 112 (5): 1151- 1155.

doi: 10.1016/j.prosdent.2013.12.021 |

| 7 | 崔丹, 刘逵仲, 张兆钰, 等. 二氧化锆与钴铬合金修复体精细抛光后对天然牙磨耗的影响[J]. 口腔医学, 2018, 38 (1): 10- 14. |

| 8 | 胡国新, 杨瑛, 江月梅, 等. 微波烧结与常规烧结对牙科用氧化锆摩擦磨损性能的影响[J]. 华西口腔医学杂志, 2017, 35 (2): 150- 154. |

| 9 | Li H , Zhou ZR . Wear behaviour of human teeth in dry and artificial saliva conditions[J]. Wear, 2001, 249 (10/11): 980- 984. |

| 10 |

Selvaraj U , Koli DK , Jain V , et al. Evaluation of the wear of glazed and polished zirconia crowns and the opposing natural teeth: A clinical pilot study[J]. J Prosthet Dent, 2021, 126 (1): 52- 57.

doi: 10.1016/j.prosdent.2020.04.007 |

| 11 | 陈济芬, 丁宏. 抛光及上釉对氧化锆全冠与釉质间磨耗性能的影响[J]. 国际口腔医学杂志, 2016, 43 (2): 165- 167. |

| 12 |

黎敏斯, 周丽琰, 苏晓晖. 不同表面处理全解剖式氧化锆全瓷冠磨耗性能的对比研究[J]. 临床口腔医学杂志, 2018, 34 (10): 591- 594.

doi: 10.3969/j.issn.1003-1634.2018.10.005 |

| 13 | Deval P , Tembhurne J , Gangurde A , et al. A clinical comparative evaluation of the wear of enamel antagonist to monolithic zirconia and metal-ceramic crowns[J]. Int J Prosthodont, 2021, 34 (6): 744- 751. |

| 14 | Alfrisany NM , Shokati B , Tam LE , et al. Simulated occlusal adjustments and their effects on zirconia and antagonist artificial enamel[J]. J Adv Prosthodont, 2019, 11 (3): 162- 168. |

| 15 | Branco AC , Silva R , Jorge H , et al. Tribological performance of the pair human teeth vs. 3D printed zirconia: An in vitro chewing simulation study[J]. J Mech Behav Biomed Mater, 2020, 110, 103900. |

| 16 | 郑靖, 沙伟, 周仲荣. 不同年龄段天然牙的摩擦磨损行为研究[J]. 摩擦学学报, 2004, 24 (5): 471- 475. |

| [1] | 唐仁韬,李欣海,于江利,冯琳,高学军. 复合树脂与玻璃陶瓷微拉伸粘接强度的体外研究[J]. 北京大学学报(医学版), 2020, 52(4): 755-761. |

|