北京大学学报(医学版) ›› 2024, Vol. 56 ›› Issue (2): 345-351. doi: 10.19723/j.issn.1671-167X.2024.02.023

成型方向对3D打印口腔义齿基托树脂材料物理性能及力学性能的影响

- 北京大学口腔医学院·口腔医院材料研究室, 国家口腔医学中心, 国家口腔疾病临床医学研究中心, 口腔生物材料和数字诊疗装备国家工程研究中心, 北京大学口腔医学院口腔医疗器械检验中心, 国家药品监督管理局口腔材料重点实验室, 口腔数字化医疗技术和材料国家工程实验室, 口腔数字医学北京市重点实验室, 北京 100081

Effect of printing orientation on physical and mechanical properties of 3D printing prosthodontic base resin materials

Xinxin ZHAN,Lulu CAO,Dong XIANG,Hao TANG,Dandan XIA*( ),Hong LIN*(

),Hong LIN*( )

)

- Department of Dental Materials, Peking University School and Hospital of Stomatology & National Center for Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Research Center of Oral Biomaterials and Digital Medical Devices & NMPA Key Laboratory for Dental Materials & Dental Medical Devices Testing Center & Beijing Key Laboratory of Digital Stomatology & National Engineering Laboratory for Digital and Material Technology of Stomatology, Beijing 100081, China

摘要:

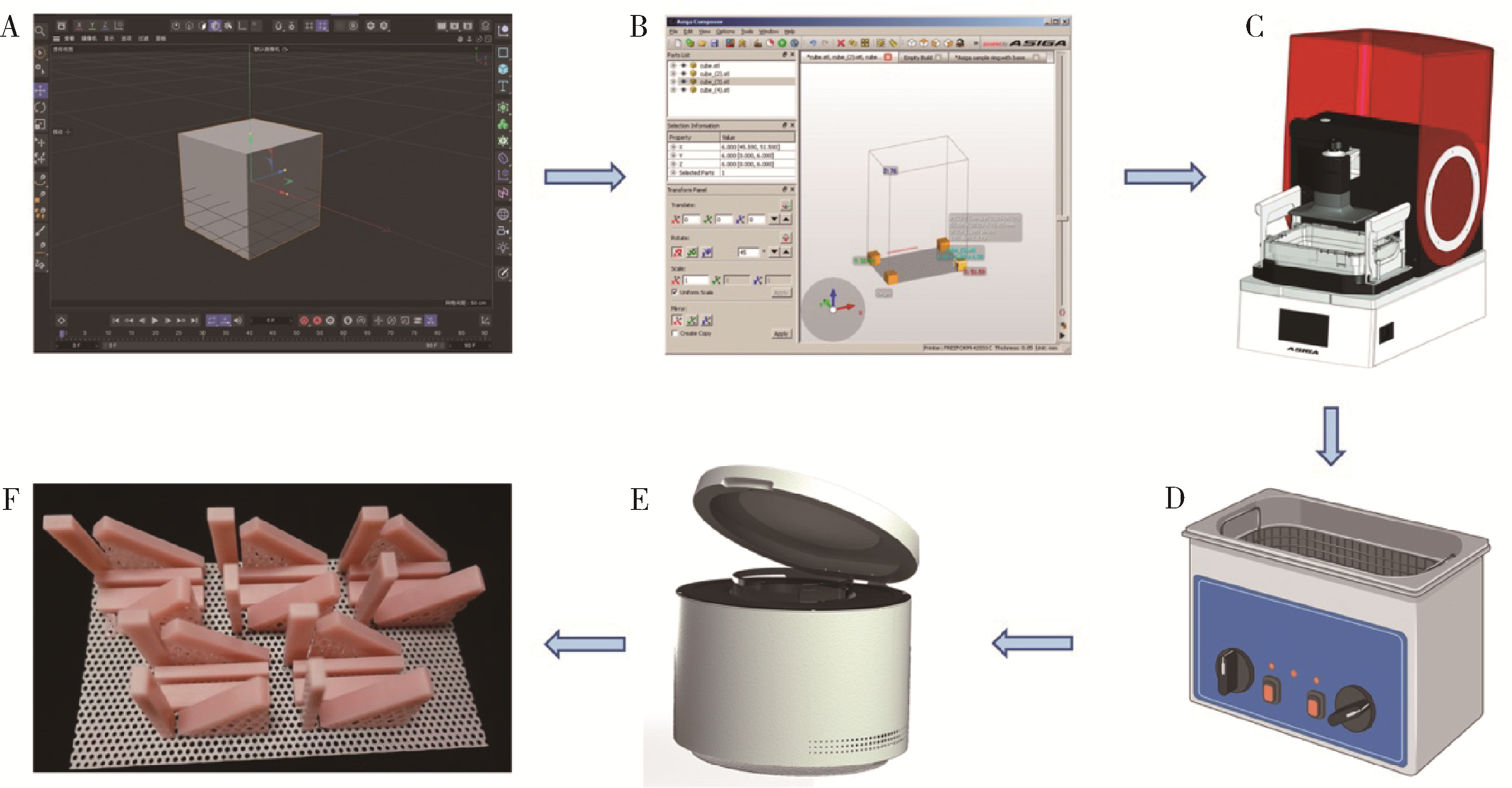

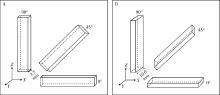

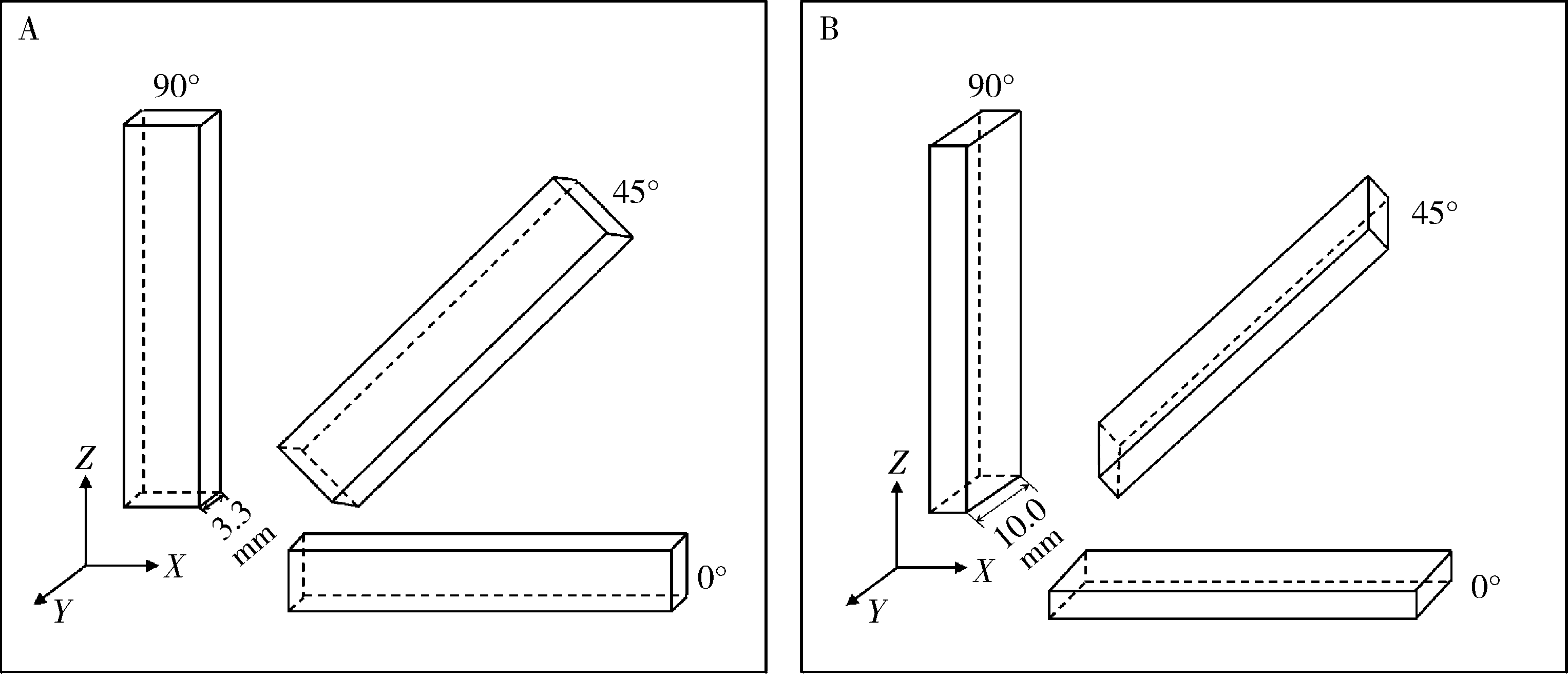

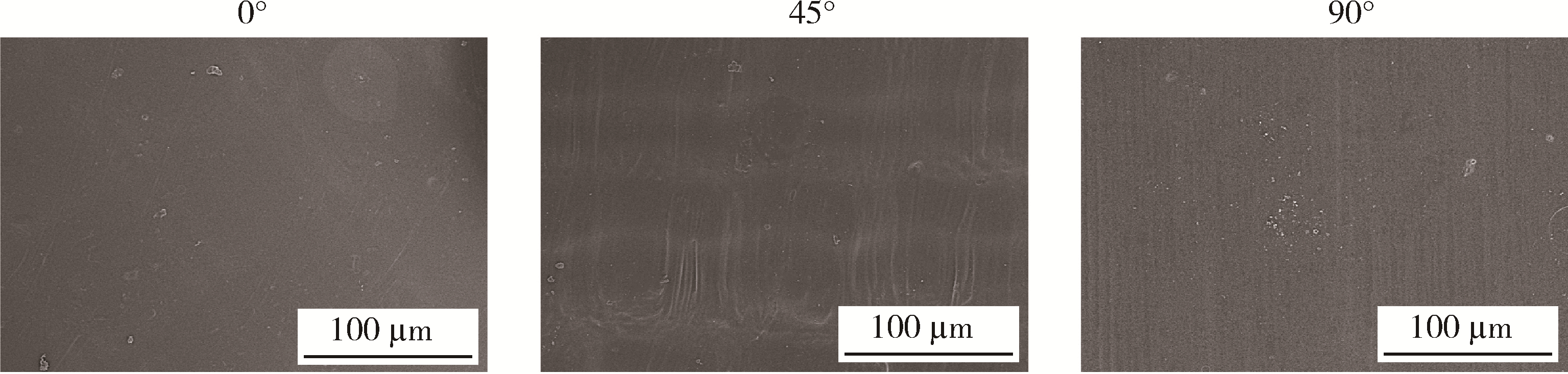

目的: 分析成型方向对打印件的表面特征、弹性模量、挠曲强度及断裂韧性的影响及其与受力方向之间的关系, 为口腔义齿基托树脂材料的临床应用提供科学依据和指导。方法: 采用3D打印技术使用义齿基托树脂材料打印义齿基托树脂试样, 试样形状及尺寸参考目前常规义齿基托材料检测标准。检测物理性能的试样为圆柱体(直径15 mm、厚1 mm), 在Z轴的不同角度方向上(0°、45°、90°)进行打印。扫描电镜观察经不同方向打印后试样的表面微观形貌; 试样经色稳定仪浸水光照后观察其颜色稳定性; 利用粗糙度仪分析试样表面粗糙程度; 用维氏硬度计测量硬度。检测力学性能的试样为长方体(检测弹性模量和挠曲强度: 长64 mm、宽10 mm、高3.3 mm; 检测断裂韧性: 长39 mm、高8.0 mm、宽4.0 mm), 分为W、H两组, W组以长×宽为底面, 平行X、Y轴平面, 自下而上沿Z轴开始打印, H组以长×高为底面, 平行X、Y轴平面, 自下而上沿Z轴开始打印, 两组成型角度均分为0°、45°和90°, 通过万能力学试验机研究其弹性模量、挠曲强度和断裂韧性。采用SPSS 22.0软件对数据进行统计分析。结果: 表面形貌和粗糙度与成型方向密切相关, 0°、45°及90°试样之间差异具有统计学意义, 0°试样表面最光滑(粗糙度 < 1 μm), 45°试样表面最粗糙(粗糙度>3 μm)。0°试样硬度最佳[(196.13±0.20) MPa], 与90°试样[(186.62±4.81) MPa]比较差异具有统计学意义(P < 0.05)。试样的力学性能与打印方向也密切相关, W组45°试样的弹性模量、挠曲强度及断裂韧性与其他方向试样比较均为最高, 差异具有统计学意义。弹性模量结果显示, H组中, 45°试样弹性模量最高, 与0°和90°试样比较差异具有统计学意义(P < 0.05);W组中0°及45°试样高于90°试样(P < 0.05);且W组0°及45°试样的弹性模量均显著高于H组0°及45°试样(P < 0.05)。挠曲强度结果显示, H组各角度试样之间差异无统计学意义, W组中90°试样强度最小, 与0°及45°试样之间比较差异具有统计学意义(P < 0.05), 且W组0°及45°试样的强度均显著高于H组0°及45°试样(P < 0.05)。断裂韧性结果显示, H组各角度试样断裂韧性均低于义齿基托材料检测标准规定的1.9 MPa m1/2; W组45°试样最高, 与0°及90°试样比较差异具有统计学意义(P < 0.05), 90°试样断裂韧性低于1.9 MPa m1/2。结论: 成型方向为0°的试样在物理性能上相对较优, 而45°试样具有最优的力学性能; 以长×高为底面沿Z轴不同方向打印的试样(H组)以及以长×宽为底面沿Z轴90°打印的试样(W组90°)的断裂韧性尚不满足临床要求, 提示3D打印义齿基托树脂性能受打印方向影响, 只有各个方向打印试样的各项性能均满足义齿基托材料检测标准的最低要求, 才可用于临床。

中图分类号:

- R783.1

| 1 | da Silva TM , Immich F , de Araujo TS , et al. Photosensitive resins used in additive manufacturing for oral application in dentistry: A scoping review from lab to clinic[J]. J Mech Behav Biomed Mater, 2023, 141 (5): 105732. |

| 2 |

Gülcan O , Günaydın K , Tamer A . The state of the art of material jetting: A critical review[J]. Polymers (Basel), 2021, 13 (16): 2829.

doi: 10.3390/polym13162829 |

| 3 | 顾波. 增材制造技术国内外应用与发展趋势[J]. 金属加工(热加工), 2022, (3): 1- 16. |

| 4 | 洪啸吟, 孟怀东, 阴金香. 立体光刻技术[J]. 感光科学与光化学, 1997, 15 (3): 85- 95. |

| 5 |

Yoo SY , Kim SK , Heo SJ , et al. Dimensional accuracy of dental models for three-unit prostheses fabricated by various 3D printing technologies[J]. Materials (Basel), 2021, 14 (6): 1550.

doi: 10.3390/ma14061550 |

| 6 |

Nasiry-Khanlar L , Revilla-León M , Barmak AB , et al. Surface roughness and shear bond strength to composite resin of additively manufactured interim restorative material with different printing orientations[J]. J Prosthet Dent, 2023, 129 (5): 788- 795.

doi: 10.1016/j.prosdent.2021.08.010 |

| 7 |

Shim JS , Kim JE , Jeong SH , et al. Printing accuracy, mechanical properties, surface characteristics, and microbial adhesion of 3D-printed resins with various printing orientations[J]. J Prosthet Dent, 2020, 124 (4): 468- 475.

doi: 10.1016/j.prosdent.2019.05.034 |

| 8 |

Yan X , Jiang R , Lin H , et al. Oriented face-centered cubic to hexagonal close-packed martensitic transition, grain morphology, and mechanical properties of Co-Cr alloy fabricated by selective laser melting[J]. J Prosthet Dent, 2022, 127 (2): 282- 287.

doi: 10.1016/j.prosdent.2020.07.036 |

| 9 |

Xiang D , Xu Y , Lin H , et al. Dental zirconia fabricated by stereolithography: Accuracy, translucency and mechanical properties in different build orientations[J]. Ceram Int, 2021, 47 (20): 28837- 28847.

doi: 10.1016/j.ceramint.2021.07.044 |

| 10 | 黄华莉, 左伟文, 石磊, 等. 义齿树脂基托材料颜色稳定性研究进展[J]. 口腔医学研究, 2014, 30 (3): 276- 277. |

| 11 |

Mazurek-Popczyk J , Nowicki A , Arkusz K , et al. Evaluation of biofilm formation on acrylic resins used to fabricate dental temporary restorations with the use of 3D printing technology[J]. BMC Oral Health, 2022, 22 (1): 442.

doi: 10.1186/s12903-022-02488-5 |

| 12 |

Yacob N , Ahmad NA , Safii SH , et al. Is microbial adhesion affected by the build orientation of a 3-dimensionally printed denture base resin[J]. J Prosthet Dent, 2023, 130 (1): 131.e1- 131.e7.

doi: 10.1016/j.prosdent.2023.04.017 |

| 13 |

Alharbi N , Osman RB . Does build angle have an influence on surface roughness of anterior 3D-printed restorations? An in vitro study[J]. Int J Prosthodont, 2021, 34 (4): 505- 510.

doi: 10.11607/ijp.7100 |

| 14 | Ligon SC , Liska R , Stampfl J , et al. Polymers for 3D printing and customized additive manufacturing[J]. Chem Rev, 2017, 117 (15): 10212- 10290. |

| 15 | Prpić V , Schauperl Z , Ćatić A , et al. Comparison of mechanical properties of 3D-printed, CAD/CAM, and conventional denture base materials[J]. J Prosthodont, 2020, 29 (6): 524- 528. |

| 16 |

de Oliveira Limírio JPJ , Gomes JML , Alves Rezende MCR , et al. Mechanical properties of polymethyl methacrylate as a denture base: Conventional versus CAD-CAM resin: A systematic review and meta-analysis of in vitro studies[J]. J Prosthet Dent, 2022, 128 (6): 1221- 1229.

doi: 10.1016/j.prosdent.2021.03.018 |

| 17 |

Mann RS , Ruse ND . Fracture toughness of conventional, milled and 3D printed denture bases[J]. Dent Mater, 2022, 38 (9): 1443- 1451.

doi: 10.1016/j.dental.2022.06.029 |

| 18 | Gungor H , Gundogdu M , Alkurt M , et al. Effect of polymerization cycles on flexural strengths and microhardness of different denture base materials[J]. Dent Mater J, 2017, 36 (2): 168- 173. |

| [1] | 胡攀攀,李彦,刘啸,唐彦超,李梓赫,刘忠军. 自稳式人工椎体在颈椎前路手术中的应用[J]. 北京大学学报(医学版), 2024, 56(1): 161-166. |

| [2] | 周华,王仁吉,刘忠军,刘晓光,吴奉梁,党礌,韦峰. 3D打印人工椎体在颈椎脊索瘤全脊椎切除术中的应用[J]. 北京大学学报(医学版), 2023, 55(1): 144-148. |

| [3] | 开地尔娅·阿不都热合曼,张荣赓,钱浩楠,邹振洋,丹尼娅·叶斯涛,范田园. 个性化剂量熔融沉积成型3D打印茶碱片剂的制备和体外评价[J]. 北京大学学报(医学版), 2022, 54(6): 1202-1207. |

| [4] | 孙玉春,郭雨晴,陈虎,邓珂慧,李伟伟. 口腔精准仿生修复技术的自主创新研发与转化[J]. 北京大学学报(医学版), 2022, 54(1): 7-12. |

| [5] | 张达,王林川,周彦恒,刘晓默,李晶. 3D打印间接粘接托槽精度[J]. 北京大学学报(医学版), 2017, 49(4): 704-708. |

| [6] | 王圣林,杨钟玮,闫明,刘忠军. 术中CT引导下寰枢椎复位、固定[J]. 北京大学学报(医学版), 2017, 49(3): 512-517. |

| [7] | 郭福新,姜玉良,吉喆,彭冉,孙海涛,王俊杰. 3D打印非共面模板辅助CT引导125Ⅰ粒子植入治疗锁骨上复发转移癌的剂量学研究[J]. 北京大学学报(医学版), 2017, 49(3): 506-511. |

| Viewed | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Full text 177

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Abstract 272

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

Cited |

|

|||||||||||||||||||||||||||||||||||||||||||||||||

| Shared | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Discussed | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

||