北京大学学报(医学版) ›› 2022, Vol. 54 ›› Issue (3): 565-571. doi: 10.19723/j.issn.1671-167X.2022.03.025

不同椅旁可切削修复材料序列抛光时间及表面粗糙度与光泽度的比较

- 1. 北京大学口腔医学院·口腔医院牙体牙髓科, 国家口腔医学中心, 国家口腔疾病临床医学研究中心, 口腔生物材料和数字诊疗装备国家工程研究中心, 口腔数字医学北京市重点实验室, 国家卫生健康委员会口腔医学计算机应用工程技术研究中心, 国家药品监督管理局口腔生物材料重点实验室, 北京 100081

2. Department of Endodontics, Dental College of Georgia at Augusta University, Augusta GA30912, USA

Surface roughness, gloss and sequential polishing times of various chairside computer aided design/manufacturing restorative materials

Hao LUO1,Fu-cong TIAN2,Xiao-yan WANG1,*( )

)

- 1. Department of Cariology and Endodontology, Peking University School and Hospital of Stomatology & National Center of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Research Center of Oral Biomaterials and Digital Medical Devices & Beijing Key Laboratory of Digital Stomatology & NHC Research Center of Engi-neering and Technology for Computerized Dentistry & NMPA Key Laboratory for Dental Materials, Beijing 100081, China

2. Department of Endodontics, Dental College of Georgia at Augusta University, Augusta GA30912, USA

摘要:

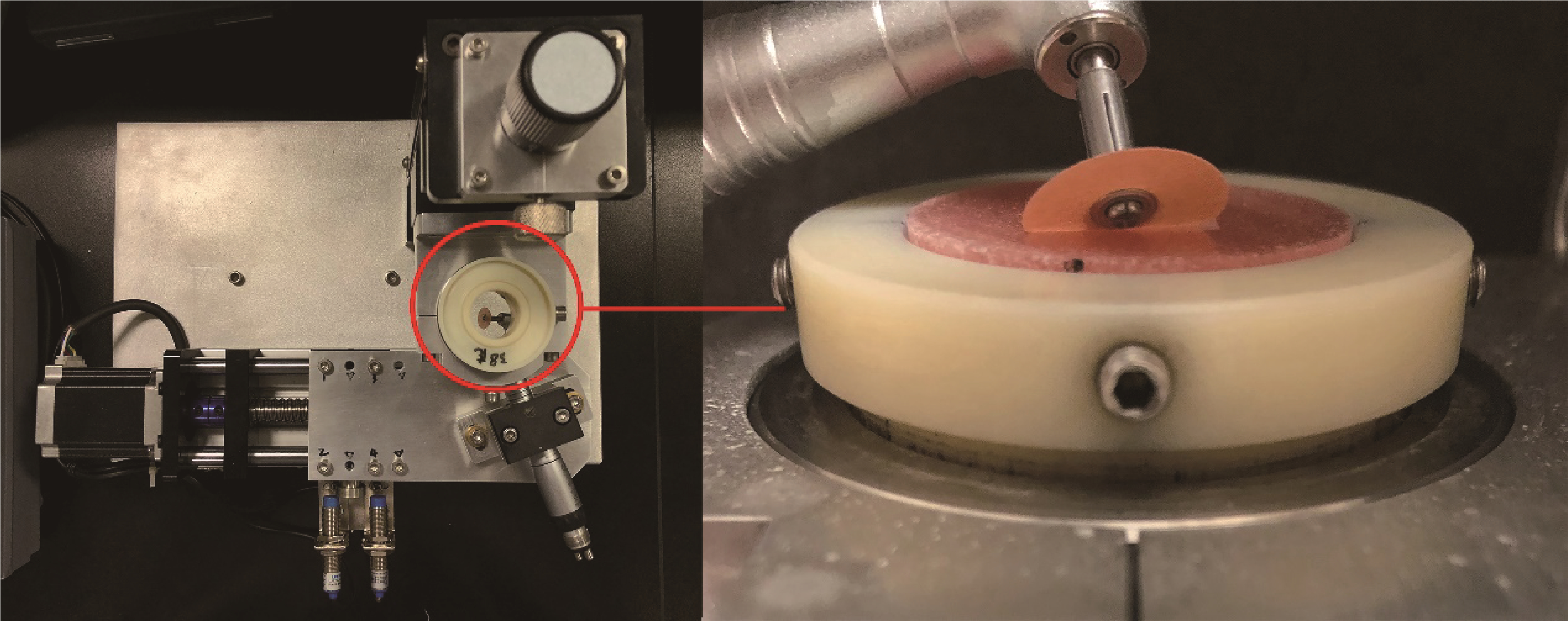

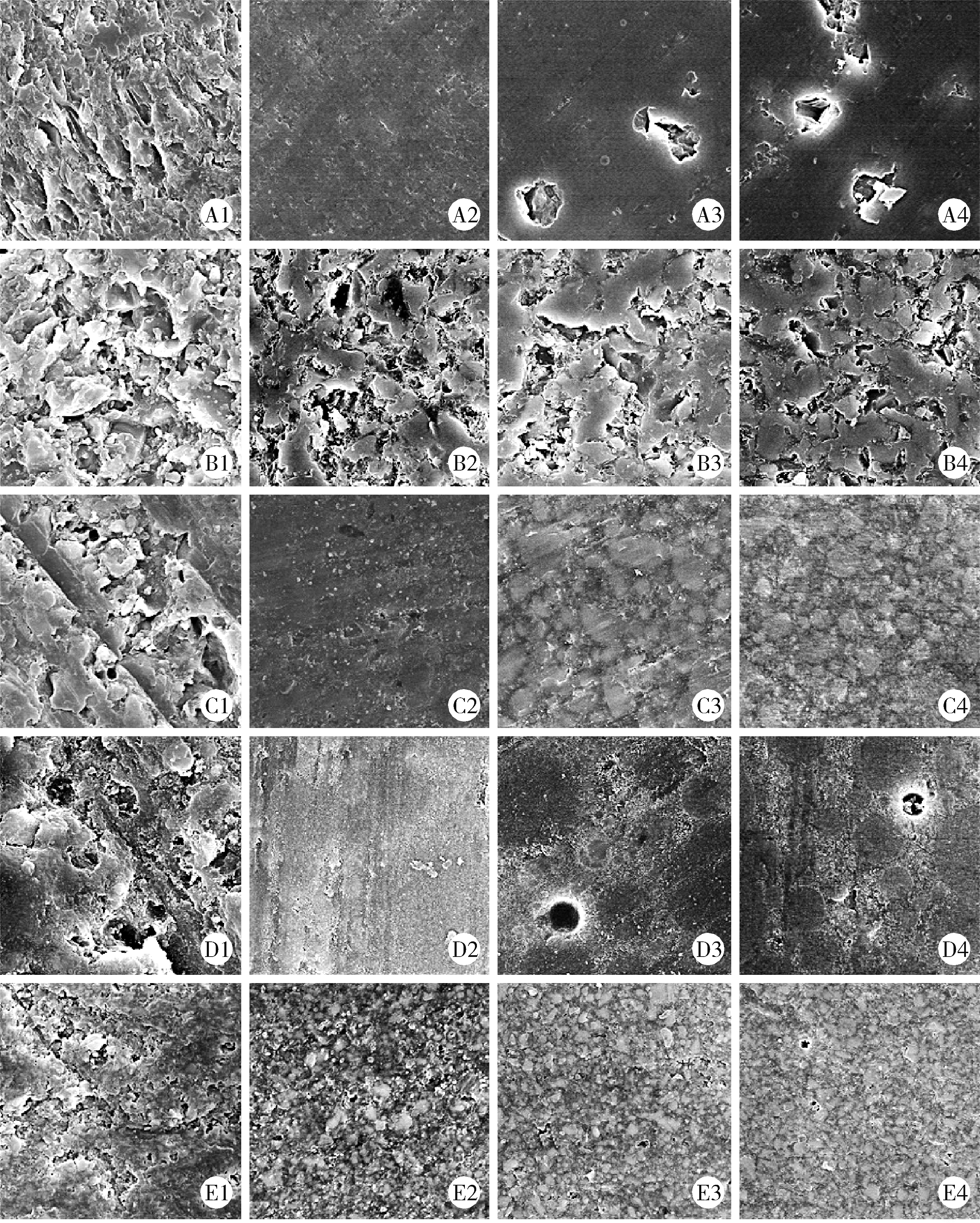

目的: 比较不同种类计算机辅助设计/辅助制作(computer aided design/manufacturing, CAD/CAM)修复材料抛光后表面粗糙度值(Ra值)与光泽度值的差异, 测定适宜的抛光时间, 为操作者抛光椅旁可切削修复体提供参考。方法: 选择5种不同种类CAD/CAM修复材料长石瓷(vita mark Ⅱ, VM)、弹性瓷(vita enamic, VE)、优韧瓷(lava ulimate, LU)、复合树脂A(shofu block HC, SB)和复合树脂B(brilliant crios, BC), 每种材料制备6个试样, 共30个试样。将试样固定于自制抛光装置, 使用Sof-Lex抛光碟系统中的中碟(medium disk, M碟, 磨粒粒径10~40 μm)、细碟(fine disk, F碟, 磨粒粒径3~9 μm)和超细碟(superfine disk, SF碟, 磨粒粒径1~7 μm)依次对试样进行序列抛光。试样每抛光10 s测量一次Ra值及光泽度值, 数值不再变化时更换下一级抛光碟, 每个抛光碟仅使用一次。更换下一级抛光碟的同时记录试样的Ra值、光泽度值以及抛光时间, 实验完成后用SPSS 24.0软件进行统计学分析。结果: 序列抛光后所有材料Ra值较抛光前显著降低(P < 0.05), 光泽度值显著升高(P < 0.05)。不同材料间的Ra值差异无统计学意义(P>0.05), 而LU的光泽度值[(68.1±4.5) GU]与SB的光泽度值[(68.2±5.8) GU]显著高于VE[(48.1±8.1) GU]与BC[(53.2±5.8) GU], P < 0.05。达到最佳Ra值和光泽度值, VM [40(30, 55) s]所需总抛光时间最短, VE [140(135, 145) s]、LU [130(120, 140) s]、SB [140(130, 150) s]与BC [130(120, 140) s]的抛光时间差异无统计学意义。结论: 所有CAD/CAM修复材料经Sof-Lex抛光碟系统序列抛光后均能显著降低表面粗糙度值和提高光泽度值; 不同材料达到最佳表面粗糙度和光泽度所需的抛光时间不同; 推荐使用Sof-Lex系统抛光时, 对于长石瓷, 仅用M碟抛光40 s即可。对于弹性瓷、优韧瓷、复合树脂A与复合树脂B, 要序列使用M碟、F碟和SF碟抛光, 总体抛光时间约130~140 s。

中图分类号:

- R783.1

| 1 |

Blatz MB , Conejo J . The current state of chairside digital dentistry and materials[J]. Dent Clin North AM, 2019, 63 (2): 175- 197.

doi: 10.1016/j.cden.2018.11.002 |

| 2 | 刘诗铭, 刘峰. 椅旁修复材料分类和新进展[J]. 口腔医学, 2017, 37 (8): 673- 677. |

| 3 |

Pfefferle R , Luemkemann N , Wiedenmann F , et al. Different polishing methods for zirconia: impact on surface, optical, and mechanical properties[J]. Clin Oral Invest, 2020, 24 (1): 395- 403.

doi: 10.1007/s00784-019-02953-6 |

| 4 |

Kilinc H , Turgut S . Optical behaviors of esthetic CAD/CAM restorations after different surface finishing and polishing procedures and UV aging: an in vitro study[J]. J Prosthet Dent, 2018, 120 (1): 107- 113.

doi: 10.1016/j.prosdent.2017.09.019 |

| 5 |

Yuan CY , Wang XY , Gao XJ , et al. Effects of surface properties of polymer-based restorative materials on early adhesion of strep-tococcus mutans in vitro[J]. J Dent, 2016, 54, 33- 40.

doi: 10.1016/j.jdent.2016.07.010 |

| 6 | 王桃, 郭震威, 郭慧晶, 等. 不同抛光工具对陶瓷抛光效果的比较研究[J]. 华西口腔医学杂志, 2017, 35 (2): 171- 175. |

| 7 |

Flury S , Lussi A , Zimmerli B . Performance of different polishing techniques for direct CAD/CAM ceramic restorations[J]. Oper Dent, 2010, 35 (4): 470- 481.

doi: 10.2341/09-373-L |

| 8 |

Kaizer MR , de Oliveira-Ogliari A , Cenci MS , et al. Do nanofill or submicron compo-sites show improved smoothness and gloss? A systematic review of in vitro studies[J]. Dent Mater, 2014, 30 (4): e41- e78.

doi: 10.1016/j.dental.2014.01.001 |

| 9 | Jung M , Otte A , Klimek J . Is surface roughness of resin compo-sites affected by operator′ s performance?[J]. Am J Dent, 2008, 21 (1): 3- 6. |

| 10 |

Jones CS , Billington RW , Pearson GJ . Laboratory study of the loads, speeds and times to finish and polish direct restorative materials[J]. J Oral Rehabil, 2005, 32 (9): 686- 692.

doi: 10.1111/j.1365-2842.2005.01487.x |

| 11 |

Amaya-Pajares SP , Ritter AV , Resendiz CV , et al. Effect of finishing and polishing on the surface roughness of four ceramic materials after occlusal adjustment[J]. J Esthet Restor Dent, 2016, 28 (6): 382- 396.

doi: 10.1111/jerd.12222 |

| 12 | Jones CS , Billington RW , Pearson GJ . Interoperator variability during polishing[J]. Quintessence Int, 2006, 37 (3): 183- 190. |

| 13 |

Heintze SD , Reinhardt M , Muller F , et al. Press-on force during polishing of resin composite restorations[J]. Dent Mater, 2019, 35 (6): 937- 944.

doi: 10.1016/j.dental.2019.03.009 |

| 14 |

Vichi A , Fonzar RF , Goracci C , et al. Effect of finishing and po-lishing on roughness and gloss of lithium disilicate and lithium silicate zirconia reinforced glass ceramic for CAD/CAM systems[J]. Oper Dent, 2018, 43 (1): 90- 100.

doi: 10.2341/16-381-L |

| 15 |

Wilder AD Jr. , Swift EJ Jr. , May KN Jr. , et al. Effect of finishing technique on the microleakage and surface texture of resin-modified glass ionomer restorative materials[J]. J Dent, 2000, 28 (5): 367- 373.

doi: 10.1016/S0300-5712(99)00075-5 |

| 16 |

Flury S , Diebold E , Peutzfeldt A , et al. Effect of artificial toothbrushing and water storage on the surface roughness and micromechanical properties of tooth-colored CAD-CAM materials[J]. J Prosthet Dent, 2017, 117 (6): 767- 774.

doi: 10.1016/j.prosdent.2016.08.034 |

| 17 |

Heintze SD , Forjanic M , Rousson V . Surface roughness and gloss of dental materials as a function of force and polishing time in vitro[J]. Dent Mater, 2006, 22 (2): 146- 165.

doi: 10.1016/j.dental.2005.04.013 |

| 18 |

Markovic L , Jordan RA , Lakota N , et al. Micromorphology of Enamel Surface After Vital Tooth Bleaching[J]. J Endodont, 2007, 33 (5): 607- 610.

doi: 10.1016/j.joen.2007.01.011 |

| 19 |

Bollen CML , Lambrechts P , Quirynen M . Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature[J]. Dent Mater, 1997, 13 (4): 258- 269.

doi: 10.1016/S0109-5641(97)80038-3 |

| 20 |

Mörmmann WH , Stawarczyk B , Ender A , et al. Wear characteristics of current aesthetic dental restorative CAD/CAM materials: two-body wear, gloss retention, roughness and Martens hardness[J]. J Mech Behav Biomed, 2013, 20, 113- 125.

doi: 10.1016/j.jmbbm.2013.01.003 |

| 21 |

Song XF , Yin L . Induced damage zone in micro-fine dental fini-shing of a feldspathic porcelain[J]. Med Eng Phys, 2010, 32 (5): 417- 422.

doi: 10.1016/j.medengphy.2010.04.007 |

| 22 | 徐通, 高平, 魏茜茜, 等. 复合树脂的研究进展[J]. 口腔医学, 2017, 37 (11): 1053- 1056. |

| 23 | 佟舒妍, 吴音, 司文捷. 新型口腔树脂陶瓷复合材料光泽度与粗糙度的研究[J]. 稀有金属材料与工程, 2015, 44, 718- 722. |

| 24 |

Alexander-Katz R , Barrera RG . Surface correlation effects on gloss[J]. J Polym Sci Pol Phys, 1998, 36 (8): 1321- 1334.

doi: 10.1002/(SICI)1099-0488(199806)36:8<1321::AID-POLB7>3.0.CO;2-U |

| 25 |

da Costa JB , Ferracane J , Paravina RD , et al. The effect of different polishing systems on surface roughness and gloss of various resin composites[J]. J Esthet Restor Dent, 2007, 19 (4): 214- 224.

doi: 10.1111/j.1708-8240.2007.00104.x |

| 26 |

Salgado VE , Cavalcante LM , Moraes RR , et al. Degradation of optical and surface properties of resin-based composites with distinct nanoparticle sizes but equivalent surface area[J]. J Dent, 2017, 59, 48- 53.

doi: 10.1016/j.jdent.2017.02.008 |

| [1] | 赵菡,卫彦,张学慧,杨小平,蔡晴,宁成云,徐明明,刘雯雯,黄颖,何颖,郭亚茹,江圣杰,白云洋,吴宇佳,郭雨思,郑晓娜,李文静,邓旭亮. 口腔硬组织修复材料仿生设计制备和临床转化[J]. 北京大学学报(医学版), 2024, 56(1): 4-8. |

| [2] | 胡菁颖,李莉,周倩妹,丁瑞宇,尚冉,白伟. 不同调拌板对玻璃离子水门汀物理性能的影响[J]. 北京大学学报(医学版), 2019, 51(5): 964-967. |

| [3] | 张皓羽,姜婷,程明轩,张玉玮. 类瓷树脂及玻璃陶瓷牙合贴面疲劳实验前后的磨耗及表面粗糙度的变化[J]. 北京大学学报(医学版), 2018, 50(1): 73-77. |

|

||