北京大学学报(医学版) ›› 2025, Vol. 57 ›› Issue (3): 604-609. doi: 10.19723/j.issn.1671-167X.2025.03.027

基于直接法和间接法数字印模制作的高嵌体适合性评价的体外研究

- 北京大学口腔医学院·口腔医院综合科,国家口腔医学中心,国家口腔疾病临床医学研究中心,口腔生物材料和数字诊疗装备国家工程研究中心,口腔数字医学北京市重点实验室,国家卫生健康委员会口腔医学计算机应用工程技术研究中心,国家药品监督管理局口腔材料重点实验室,北京 100081

Fitness of onlays fabricated with direct and indirect CAD/CAM technology in vitro

- Department of General Dentistry, Peking University School and Hospital of Stomatology & National Center for Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Research Center of Oral Biomaterials and Digital Medical Devices & Beijing Key Laboratory of Digital Stomatology & NHC Research Center of Engineering and Technology for Computerized Dentistry & NMPA Key Laboratory for Dental Materials, Beijing 100081, China

摘要:

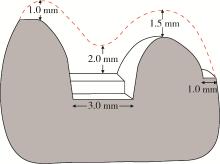

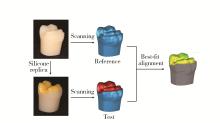

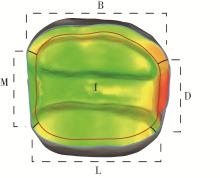

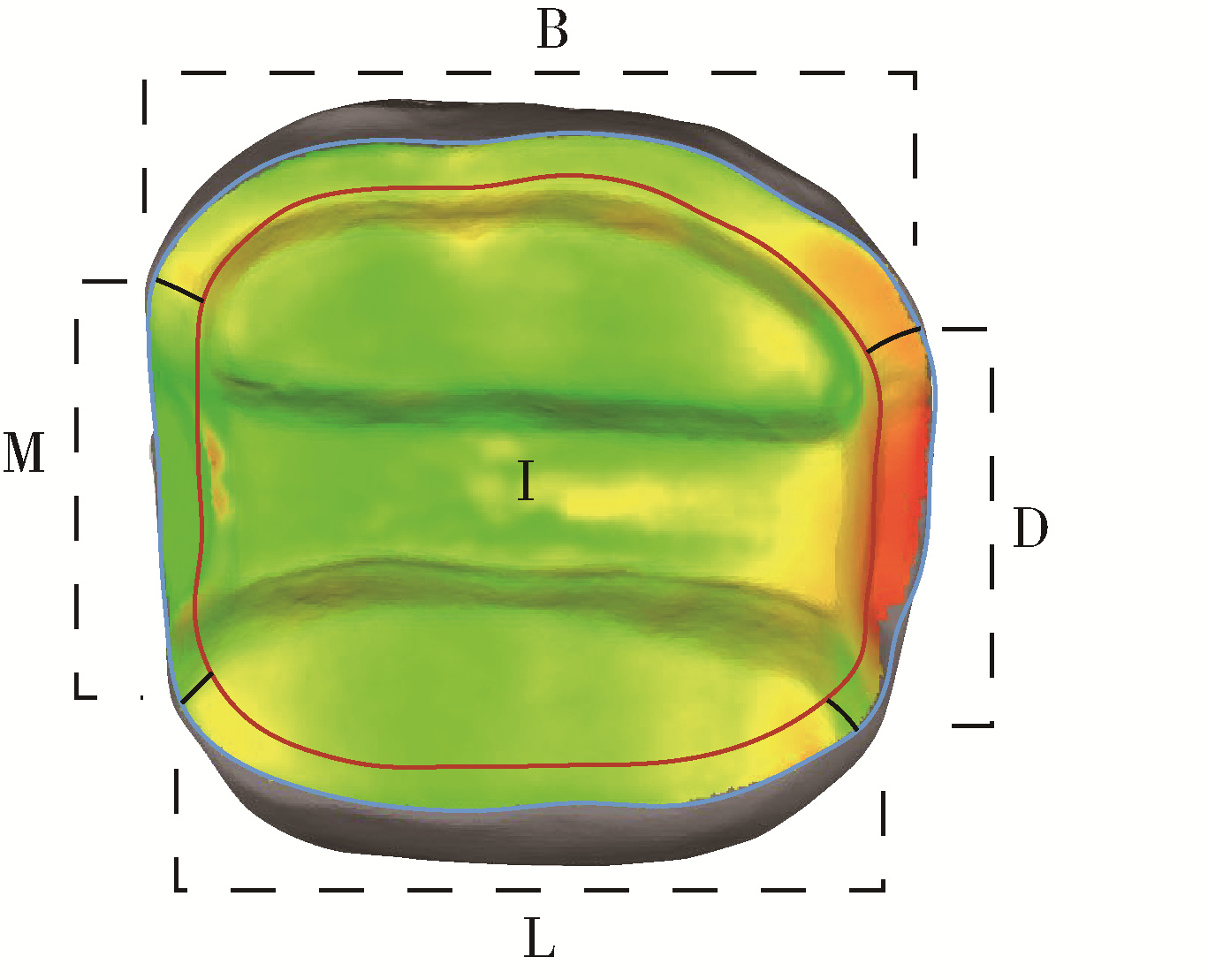

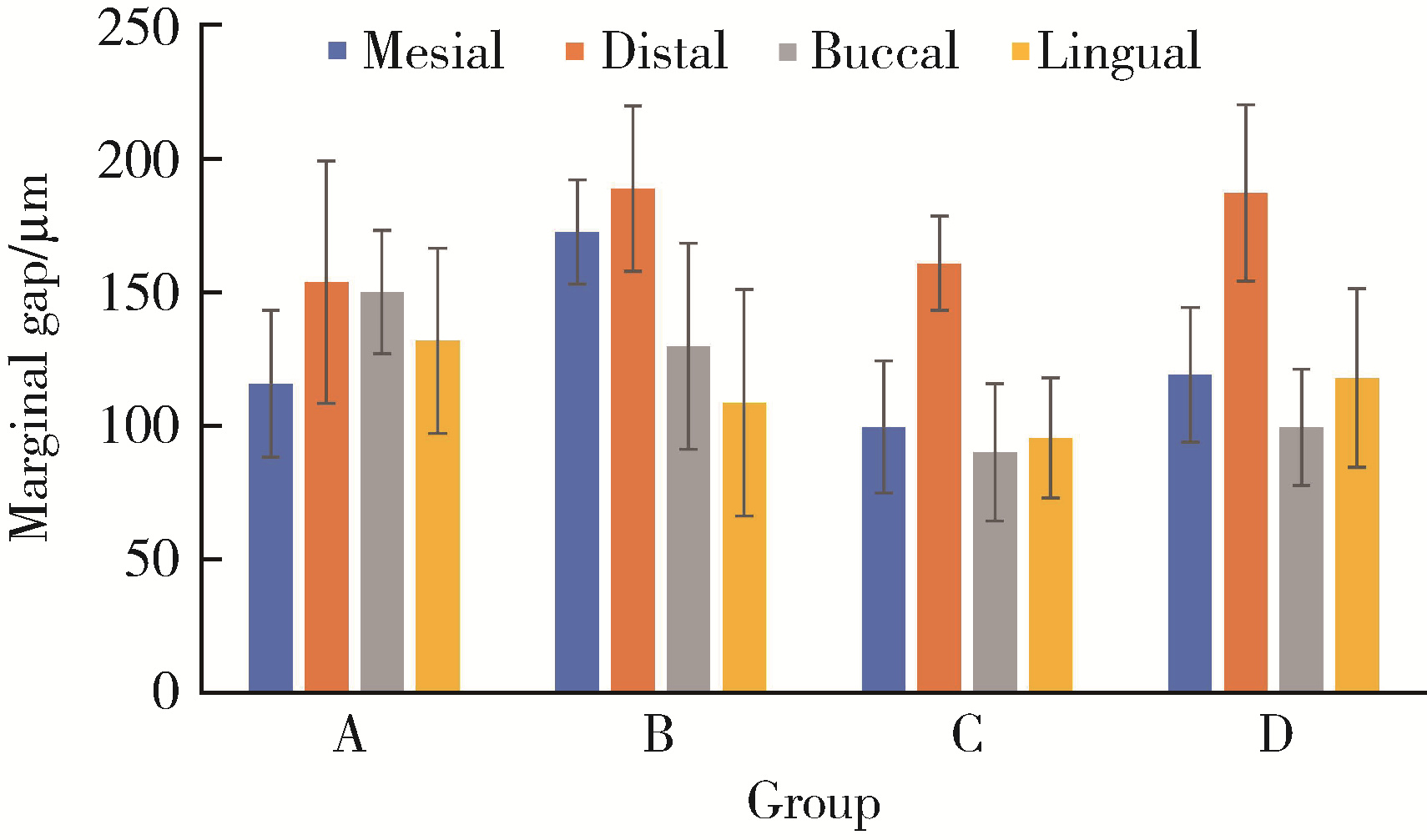

目的: 探索体外环境下,基于直接法及间接法数字印模技术制作的氧化锆及二硅酸锂增强玻璃陶瓷高嵌体的适合性。方法: 36牙位树脂人工牙48颗,随机分成A、B、C、D 4组,每组12颗,体外完成人工牙标准近中牙合远中高嵌体牙体预备,显微镜下检查预备质量。仿头模固定于牙科治疗椅,将标准人工牙列模型固定于仿头模内。将A、B组树脂人工牙依次置于人工牙列内相应位置,口内扫描仪获取36牙位数字印模。成品托盘,聚醚硅橡胶制取C、D组树脂牙列印模,灌注石膏模型,使用模型扫描仪扫描C、D组石膏模型。4组均使用数字化设计软件完成高嵌体设计,送加工部门完成高嵌体制作(A、C组使用氧化锆材料,B、D组使用二硅酸锂增强玻璃陶瓷材料),使用三维配准方法评价高嵌体边缘间隙及内部间隙。结果: 基于间接法数字印模技术制作的高嵌体的边缘间隙及内部间隙均小于直接法数字印模组(P < 0.05),各处理组远中边缘间隙值最大(P < 0.05),不同制作材料对高嵌体边缘及内部适合性均无显著影响(P>0.05)。结论: 基于间接法数字印模技术制作的高嵌体的边缘适合性及内部适合性均优于直接法,氧化锆及二硅酸锂增强玻璃陶瓷两种修复材料对高嵌体适合性没有影响。

中图分类号:

- R783.3

| 1 |

doi: 10.1016/j.dental.2019.08.103 |

| 2 |

doi: 10.1111/clr.12567 |

| 3 |

doi: 10.1007/s00784-015-1641-y |

| 4 |

doi: 10.1007/s00784-015-1626-x |

| 5 |

doi: 10.4047/jap.2015.7.6.460 |

| 6 |

doi: 10.1111/clr.12234 |

| 7 |

doi: 10.1186/1472-6831-14-10 |

| 8 |

doi: 10.1016/0022-3913(89)90170-4 |

| 9 |

doi: 10.1007/s00784-015-1504-6 |

| 10 |

doi: 10.1016/j.prosdent.2016.05.006 |

| 11 |

doi: 10.1016/j.prosdent.2015.04.001 |

| 12 |

doi: 10.1016/j.prosdent.2016.04.028 |

| 13 |

doi: 10.1016/j.prosdent.2018.06.006 |

| 14 |

|

| 15 |

doi: 10.1111/j.1532-849X.2001.00078.x |

| 16 |

|

| 17 |

doi: 10.1016/j.compbiomed.2006.05.006 |

| 18 |

姜楠, 包旭东, 岳琳. 全冠预备体终止线局部扫描正确度对整体的影响[J]. 北京大学学报(医学版), 2021, 53 (1): 102- 108.

|

| 19 |

doi: 10.1016/j.jpor.2017.05.008 |

| 20 |

doi: 10.1038/sj.bdj.4802708 |

| 21 |

doi: 10.1016/j.jdent.2013.10.002 |

| 22 |

doi: 10.1034/j.1600-0722.2003.00022.x |

| 23 |

|

| 24 |

doi: 10.1016/j.dental.2012.10.012 |

| 25 |

doi: 10.1016/j.prosdent.2014.03.017 |

| 26 |

doi: 10.1016/j.prosdent.2014.09.010 |

| 27 |

doi: 10.1111/jopr.12274 |

| 28 |

doi: 10.1016/j.prosdent.2014.05.012 |

| 29 |

doi: 10.11607/jomi.2070 |

| 30 |

doi: 10.1016/j.dental.2009.01.100 |

| 31 |

|

| 32 |

doi: 10.2174/1874210601812010160 |

| 33 |

|

| 34 |

|

| 35 |

doi: 10.1016/j.dental.2011.12.008 |

| 36 |

doi: 10.1016/j.compbiomed.2014.11.017 |

| 37 |

doi: 10.1080/17436753.2022.2069988 |

| [1] | 吴美辰,许桐楷,安伟,刘中宁,姜婷. 后牙高嵌体和 |

| [2] | 丁茜,李文锦,孙丰博,谷景华,林元华,张磊. 表面处理对氧化钇和氧化镁稳定的氧化锆种植体晶相及断裂强度的影响[J]. 北京大学学报(医学版), 2023, 55(4): 721-728. |

| [3] | 吴思妤,李娅宁,张晓,吕珑薇,刘云松,叶红强,周永胜. 上颌中切牙全瓷冠牙体预备学习曲线的预测、分析与应用[J]. 北京大学学报(医学版), 2023, 55(1): 108-113. |

| [4] | 李伟伟,陈虎,王勇,孙玉春. 氧化锆陶瓷表面硅锂喷涂层的摩擦磨损性能[J]. 北京大学学报(医学版), 2023, 55(1): 94-100. |

| [5] | 王鹃,尉华杰,孙井德,邱立新. 预成刚性连接杆用于无牙颌种植即刻印模制取的应用评价[J]. 北京大学学报(医学版), 2022, 54(1): 187-192. |

| [6] | 王铮,丁茜,高远,马全诠,张磊,葛兮源,孙玉春,谢秋菲. 氧化锆多孔表面显微形貌对成骨细胞增殖及分化的影响[J]. 北京大学学报(医学版), 2022, 54(1): 31-39. |

| [7] | 李文锦,丁茜,原福松,孙丰博,郑剑桥,鲍蕊,张磊. 飞秒激光表面处理对氧化锆表面特征及弯曲强度的影响[J]. 北京大学学报(医学版), 2021, 53(4): 770-775. |

| [8] | 杨欣,李榕,叶红强,陈虎,王勇,周永胜,孙玉春. 不同刃状边缘补偿角度的两种氧化锆全瓷冠断裂强度的评价[J]. 北京大学学报(医学版), 2021, 53(2): 402-405. |

| [9] | 徐啸翔,曹烨,赵一姣,贾璐,谢秋菲. 数字化个齿托盘制取下颌全牙列全冠预备体印模的体外评价[J]. 北京大学学报(医学版), 2021, 53(1): 54-61. |

| [10] | 郑苗,詹凌璐,刘志强,李和平,谭建国. 不同等离子体处理氧化锆对人牙龈成纤维细胞黏附能力的影响[J]. 北京大学学报(医学版), 2019, 51(2): 315-320. |

| [11] | 周团锋,王新知. 计算机辅助设计与制作的一体化氧化锆全瓷桩核5年临床观察[J]. 北京大学学报(医学版), 2018, 50(4): 680-684. |

| [12] | 焦洋, 王继德, 邓久鹏. 不同表面处理对氧化锆晶相结构及性能的影响[J]. 北京大学学报(医学版), 2018, 50(1): 49-52. |

| [13] | 廖宇,刘晓强,陈立,周建锋,谭建国. 不同表面处理方法对氧化锆与树脂水门汀粘接强度的影响[J]. 北京大学学报(医学版), 2018, 50(1): 53-57. |

| [14] | 张皓羽,姜婷,程明轩,张玉玮. 类瓷树脂及玻璃陶瓷牙合贴面疲劳实验前后的磨耗及表面粗糙度的变化[J]. 北京大学学报(医学版), 2018, 50(1): 73-77. |

| [15] | 崔新悦,佟岱,王新知,沈志坚. 对比切削与胶态成型工艺制作的氧化锆陶瓷的透光性与遮色效果[J]. 北京大学学报(医学版), 2018, 50(1): 85-90. |

|

||