北京大学学报(医学版) ›› 2019, Vol. 51 ›› Issue (1): 120-130. doi: 10.19723/j.issn.1671-167X.2019.01.022

口腔用光固化三维打印精度评价方法的建立及应用效果

- 北京大学口腔医学院·口腔医院,口腔医学数字化研究中心,口腔修复教研室 国家口腔疾病临床医学研究中心 口腔数字化医疗技术和材料国家工程实验室 口腔数字医学北京市重点实验室,北京 100081

A method to evaluate the trueness of reconstructed dental models made with photo-curing 3D printing technologies

Ning XIAO,Yu-chun SUN,Yi-jiao ZHAO( ),Yong WANG(

),Yong WANG( )

)

- Center for Digital Dentistry, Department of Prosthodontics, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

摘要:

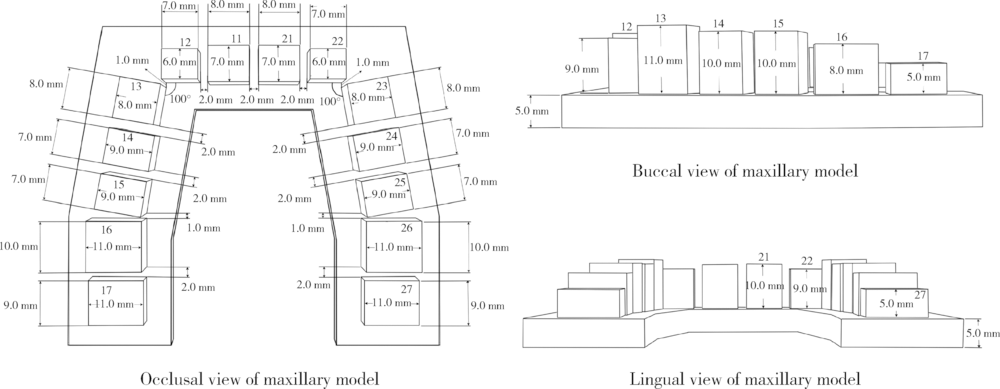

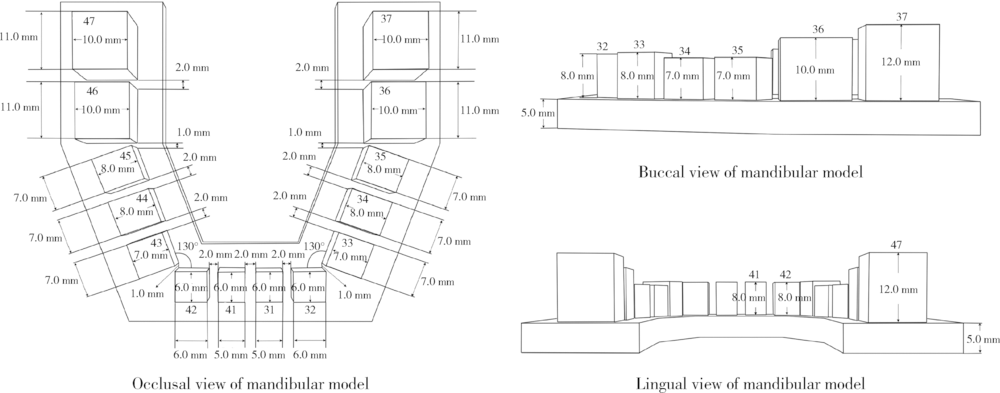

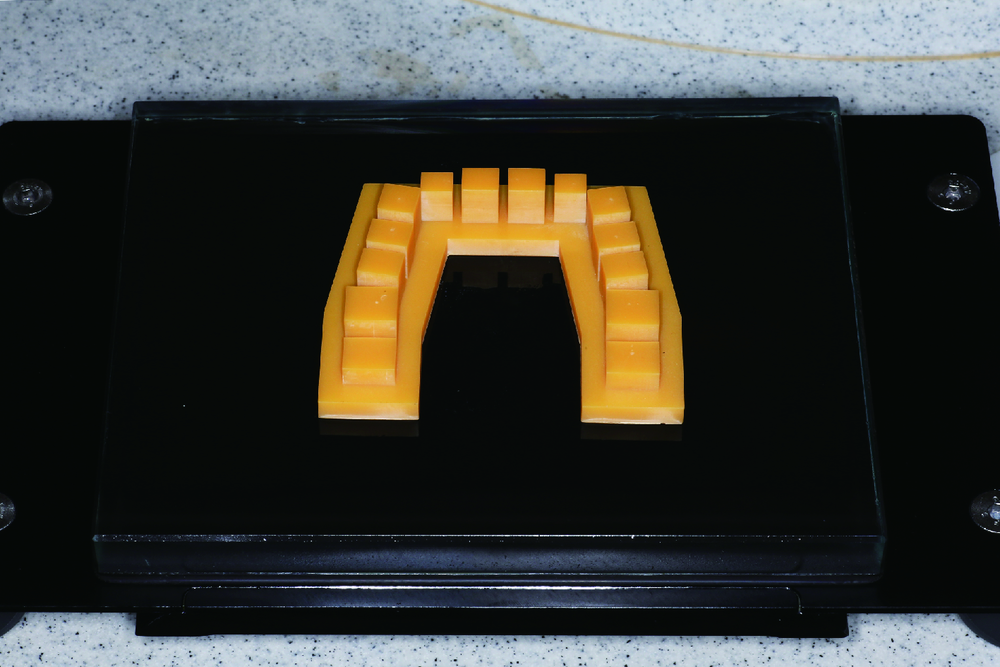

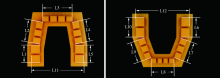

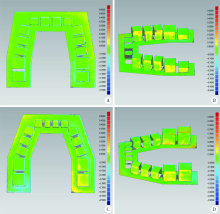

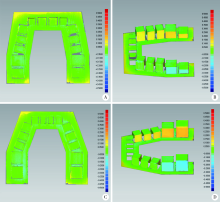

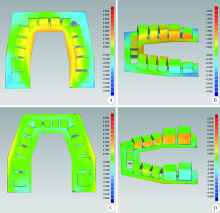

目的:建立一种光固化三维打印技术精度评价用牙颌参考模型,并借助该模型建立光固化三维打印牙颌模型准确度的多维评价方法,获得客观评价结果。方法:参考既往文献报道的中国人群恒牙及恒牙列形态学研究的统计分析数据,在3ds Max 2018软件中设计一副以简化标准长方体组合模型模拟真实牙颌模型特征的牙颌参考模型。用三款不同打印原理的光固化三维打印机进行模型打印,分别是:Objet30 Pro打印机(PJ技术)、Projet 3510 HD Plus打印机(MJP技术)和Perfactory DDP打印机(DLP技术)。通过三维扫描打印模型,在Geomagic Studio 2012软件中基于扫描数据分析打印模型的整体3D偏差、特征面的平面度、平行度和垂直度误差。利用数显卡尺对打印模型各模拟牙冠近远中径、颊舌径和牙合龈向高度以及模拟牙列进行特征尺寸测量,分析打印层内和打印层高百分比误差。结果:在三维形态误差方面,Objet30 Pro打印模型的整体3D偏差最小,Projet 3510 HD Plus和Perfactory DDP打印模型分别在垂直度和平面度方面表现最优;在特征尺寸误差方面,Objet30 Pro打印模型的打印层内和打印层高误差综合表现最优。结论:本研究建立的光固化三维打印牙颌模型精度评价模型及配套方法,可以提供较客观、全面的评价结果,具有较好的通用性,可为三维打印临床应用提供参考和指导。

中图分类号:

- R783.1

| [1] |

Bell A, Ayoub AF, Siebert P . Assessment of the accuracy of a three-dimensionalimaging system for archiving dental study models[J]. J Orthod, 2003,30(3):219-223.

doi: 10.1093/ortho/30.3.219 pmid: 14530419 |

| [2] |

雷东辉, 杨建军, 安世昌 , 等. 四种超硬石膏模型精度及抗弯强度的比较[J]. 中国组织工程研究与临床康复, 2011,15(21):3979-3982.

doi: 10.3969/j.issn.1673-8225.2011.21.043 |

| [3] |

Santoro M, Galkin S, Teredesai M , et al. Comparison of measurements made on digital and plaster models[J]. Am J Orthod Den-tofacial Orthop, 2003,124(1):101-105.

doi: 10.1016/S0889-5406(03)00152-5 pmid: 12867904 |

| [4] |

杨慧芳, 赵建江, 王勇 . 3D打印技术在口腔医学领域中的应用[J]. 中国医疗设备, 2015,30(5):63-65.

doi: 10.3969/j.issn.1674-1633.2015.05.019 |

| [5] |

Dawood A, Marti MB, Sauret-Jackson V , et al. 3D printing in dentistry[J]. Br Dent J, 2015,219(11):521-529.

doi: 10.1038/sj.bdj.2015.914 |

| [6] |

Barazanchi A, Li KC, Al-Amleh B , et al. Additive technology: update on current materials and applications in dentistry[J]. J Prosthodont, 2017,26(2):156-163.

doi: 10.1111/jopr.12510 pmid: 27662423 |

| [7] |

孙玉春, 李榕, 周永胜 , 等. 三维打印在口腔修复领域中的应用[J]. 中华口腔医学杂志, 2017,52(6):381-385.

doi: 10.3760/cma.j.issn.1002-0098.2017.06.013 |

| [8] | 王惠芸 . 我国人牙的测量和统计[J]. 中华口腔科杂志, 1959,3(7):149-155. |

| [9] |

翁希里, 于世宾, 赵守亮 , 等. 关中地区1000个汉族人恒牙解剖形态测量[J]. 牙体牙髓牙周病学杂志, 2007,17(2):75-77.

doi: 10.3969/j.issn.1005-2593.2007.02.004 |

| [10] |

涂玲, 刘良奎, 胡延佳 . 湖南地区正常恒牙牙合牙及牙弓的测量研究[J]. 中国现代医学杂志, 2003,13(24):62-64.

doi: 10.3969/j.issn.1005-8982.2003.24.019 |

| [11] |

彭惠, 卢海燕, 王昕 . 汉族青年恒牙牙冠的测量研究[J]. 现代口腔医学杂志, 2003,17(1):57-59.

doi: 10.3969/j.issn.1003-7632.2003.01.020 |

| [12] |

于跃, 许天民 . Spee曲线相关研究的回顾[J]. 中华口腔正畸学杂志, 2013,20(4):214-217.

doi: 10.3760/cma.j.issn.1674-5760.2013.04.008 |

| [13] |

Kasparova M, Grafova L, Dvorak P , et al. Possibility of reconstruction of dental plaster cast from 3D digital study models[J]. Biomed Eng Online, 2013,12:49.

doi: 10.1186/1475-925X-12-49 pmid: 23721330 |

| [14] |

Rebong RE, Stewart KT, Utreja A , et al. Accuracy of three-dimensional dental resin models created by fused deposition mo-deling, stereolithography, and Polyjet prototype technologies: A comparative study[J]. Angle Orthod, 2018,88(3):363-369.

doi: 10.2319/071117-460.1 pmid: 29509023 |

| [15] |

Keating AP, Knox J, Bibb R , et al. A comparison of plaster, digital and reconstructed study model accuracy[J]. J Orthod, 2008,35(3):191-201.

doi: 10.1179/146531207225022626 |

| [16] |

Hazeveld A, Huddleston SJ, Ren Y . Accuracy and reproducibility of dental replica models reconstructed by different rapid prototyping techniques[J]. Am J Orthod Dentofacial Orthop, 2014,145(1):108-115.

doi: 10.1016/j.ajodo.2013.05.011 pmid: 24373661 |

| [17] |

Saleh WK, Ariffin E, Sherriff M , et al. Accuracy and reprodu-cibility of linear measurements of resin, plaster, digital and printed study-models[J]. J Orthod, 2015,42(4):301-306.

doi: 10.1179/1465313315Y.0000000016 pmid: 26216658 |

| [18] |

Hwang YC, Park YS, Kim HK , et al. The evaluation of working casts prepared from digital impressions[J]. Oper Dent, 2013,38(6):655-662.

doi: 10.2341/12-352-l pmid: 23570301 |

| [19] |

Wan HW, Yusoff Y, Mardi NA . Comparison of reconstructed rapid prototyping models produced by 3-dimensional printing and conventional stone models with different degrees of crowding[J]. Am J Orthod Dentofacial Orthop, 2017,151(1):209-218.

doi: 10.1016/j.ajodo.2016.08.019 |

| [20] | 曾飞煌, 徐远志, 房莉 , 等. 应用数字化技术和快速成型技术制作牙颌模型的准确性评价[J]. 上海口腔医学, 2012,21(1):53-56. |

| [21] |

Camardella LT, de Vasconcellos VO, Breuning H . Accuracy of printed dental models made with 2 prototype technologies and different designs of model bases[J]. Am J Orthod Dentofacial Orthop, 2017,151(6):1178-1187.

doi: 10.1016/j.ajodo.2017.03.012 pmid: 28554463 |

| [22] |

Cuperus AM, Harms MC, Rangel FA , et al. Dental models made with an intraoral scanner: a validation study[J]. Am J Orthod Dentofacial Orthop, 2012,142(3):308-313.

doi: 10.1016/j.ajodo.2012.03.031 pmid: 22920696 |

| [23] |

Murugesan K, Anandapandian PA, Sharma SK , et al. Comparative evaluation of dimension and surface detail accuracy of models produced by three different rapid prototype techniques[J]. J In-dian Prosthodont Soc, 2012,12(1):16-20.

doi: 10.1007/s13191-011-0103-8 pmid: 3332309 |

| [24] |

Kim SY, Shin YS, Jung HD , et al. Precision and trueness of dental models manufactured with different 3-dimensional printing techniques[J]. Am J Orthod Dentofacial Orthop, 2018,153(1):144-153.

doi: 10.1016/j.ajodo.2017.05.025 pmid: 29287640 |

| [25] |

Dietrich CA, Ender A, Baumgartner S , et al. A validation study of reconstructed rapid prototyping models produced by two techno-logies[J]. Angle Orthod, 2017,87(5):782-787.

doi: 10.2319/01091-727.1 pmid: 28459285 |

| [26] | Jin SJ, Jeong ID, Kim JH , et al. Accuracy (trueness and precision) of dental models fabricated using additive manufacturing methods[J]. Int J Comput Dent, 2018,21(2):107-113. |

| [27] |

Ishida Y, Miyasaka T . Dimensional accuracy of dental casting patterns created by 3D printers[J]. Dent Mater J, 2016,35(2):250-256.

doi: 10.4012/dmj.2015-278 pmid: 27041015 |

| [28] |

方浩博, 陈继民 . 基于数字光处理技术的3D打印技术[J]. 北京工业大学学报, 2015,41(12):1775-1782.

doi: 10.11936/bjutxb2015070050 |

| [29] | 何岷洪, 宋坤, 莫宏斌 , 等. 3D打印光敏树脂的研究进展[J]. 功能高分子学报, 2015,28(1):102-108. |

| [30] |

Stansbury JW, Idacavage MJ . 3D printing with polymers: Challenges amongexpanding options and opportunities[J]. Dent Mater, 2016,32(1):54-64.

doi: 10.1016/j.dental.2015.09.018 pmid: 26494268 |

| [31] |

Snyder TJ, Andrews M, Weislogel M , et al. 3D systems’ techno-logy overview and new applications in manufacturing, engineering, science, and education[J]. 3D Print Addit Manuf, 2011,1(3):169-176.

doi: 10.1089/3dp.2014.1502 pmid: 28473997 |

| [1] | 刘思民,赵一姣,王晓燕,王祖华. 动态导航下不同深度环钻定位精确度的体外评价[J]. 北京大学学报(医学版), 2022, 54(1): 146-152. |

| [2] | 徐啸翔,曹烨,赵一姣,贾璐,谢秋菲. 数字化个齿托盘制取下颌全牙列全冠预备体印模的体外评价[J]. 北京大学学报(医学版), 2021, 53(1): 54-61. |

| [3] | 萧宁,孙玉春,赵一姣,王勇. 三种数字化分析算法测量咬合接触分布及面积的对比研究[J]. 北京大学学报(医学版), 2020, 52(1): 144-151. |

| [4] | 戴帆帆,刘怡,许天民,陈贵. 探索成人正畸前后下颌三维数字化模型的重叠方法[J]. 北京大学学报(医学版), 2018, 50(2): 271-278. |

| [5] | 叶红强,柳玉树,刘云松,宁静,赵一姣,周永胜. 口内数码摄影辅助构建三维彩色数字牙列模型[J]. 北京大学学报(医学版), 2016, 48(1): 138-142. |

| [6] | 秦一飞, 许天民. 在数字化牙颌模型上确定平面的可重复性[J]. 北京大学学报(医学版), 2015, 47(3): 536-540. |

| [7] | 胡攀攀, 于淼, 刘晓光, 陈仲强, 刘忠军. Lenke 1型青少年特发性脊柱侧弯脊柱-骨盆矢状位与冠状位参数的相关性[J]. 北京大学学报(医学版), 2015, 47(2): 248-252. |

| [8] | 王宗琦, 王晓霞, 李自力, 伊彪, 梁成, 王兴. 3种缝合方法控制上颌Le Fort Ⅰ型截骨术后鼻翼宽度的效果比较[J]. 北京大学学报(医学版), 2015, 47(1): 104-108. |

| [9] | 宋杨, 孙玉春, 赵一姣, 王勇, 吕培军. 牙颌模型三维扫描仪精度定量评价[J]. 北京大学学报(医学版), 2013, 45(1): 140-144. |

| [10] | 郭惠杰, 岳林. 粪肠球菌在根管内定植模式的体外研究[J]. 北京大学学报(医学版), 2009, 41(6): 699-701. |

| [11] | 赵一姣, 王勇, 吕培军. 一种基于数字化牙颌模型的三维咬合分析方法[J]. 北京大学学报(医学版), 2008, 40(1): 109-111. |

| [12] | 王勇, 赵一姣, 吕培军, 李忠科. 一种牙尖交错位上下颌模型的扫描方法[J]. 北京大学学报(医学版), 2006, 38(3): 298-300. |

|

||