北京大学学报(医学版) ›› 2019, Vol. 51 ›› Issue (1): 131-135. doi: 10.19723/j.issn.1671-167X.2019.01.023

控制记忆合金丝镍钛根管锉弯曲性能有限元分析模型的构建及力学分析

- 1. 北京大学第一医院口腔科,北京 100034

2. 首都医科大学宣武医院口腔科,北京 100053

3. 北京大学口腔医学院·口腔医院,第二门诊部 国家口腔疾病临床医学研究中心 口腔数字化医疗技术和材料国家工程实验室 口腔数字医学北京市重点实验室,北京 100101

Construction and mechanical analysis of finite element model for bending property of controlled memory wire nickel-titanium rotary file

Hong-yu FU1,Fang-fang WANG2,Xiao-mei HOU3,△( )

)

- 1. Department of Stomatology, Peking University First Hospital, Beijing 100034, China

2. Department of Stomatology, Xuanwu Hospital, Capital Medical University, Beijing 100053, China

3. Second Clinical Division, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100101, China

摘要:

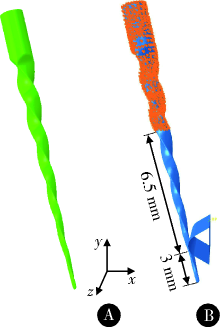

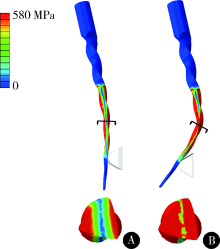

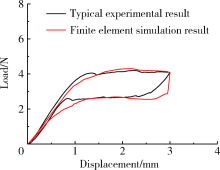

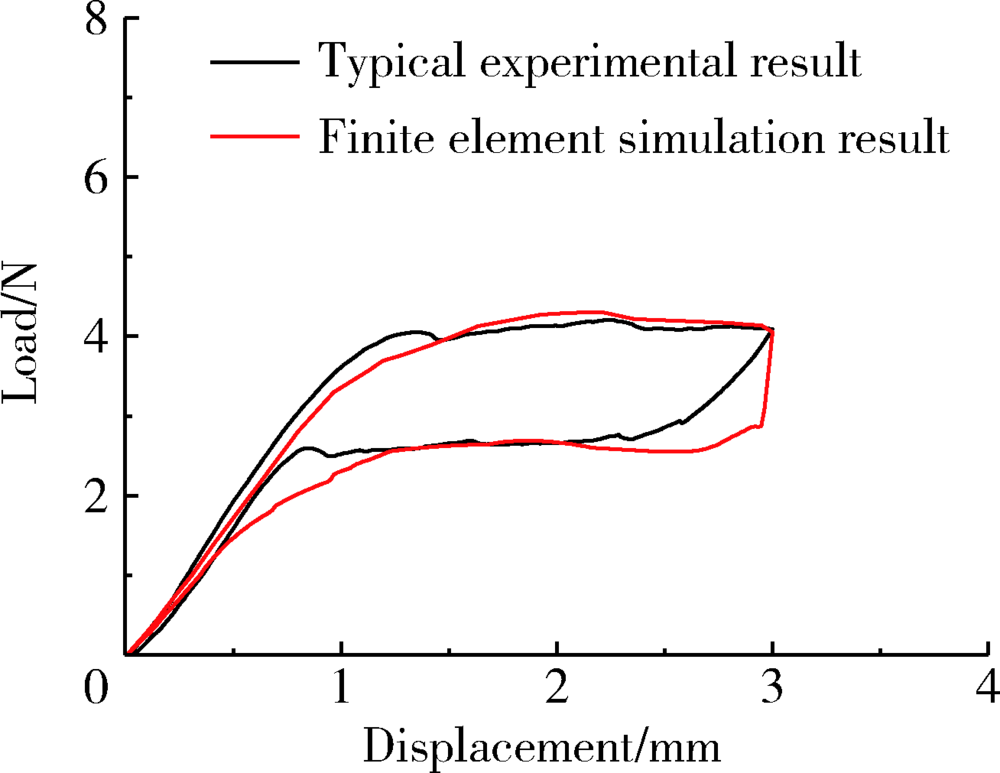

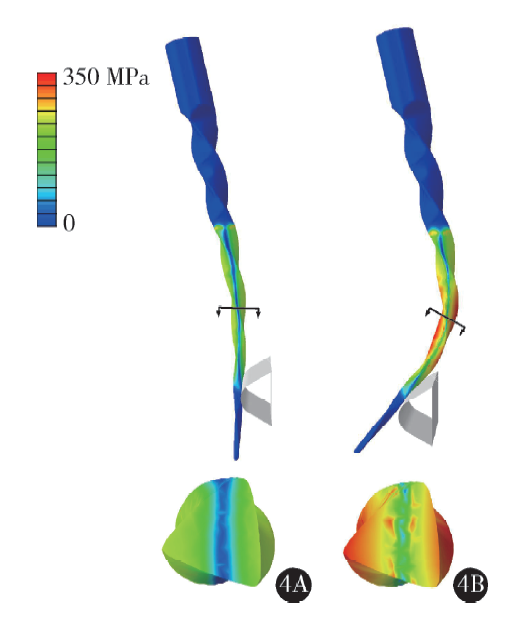

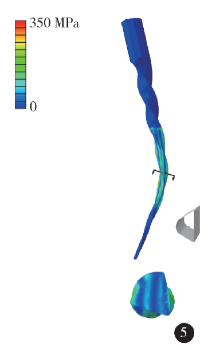

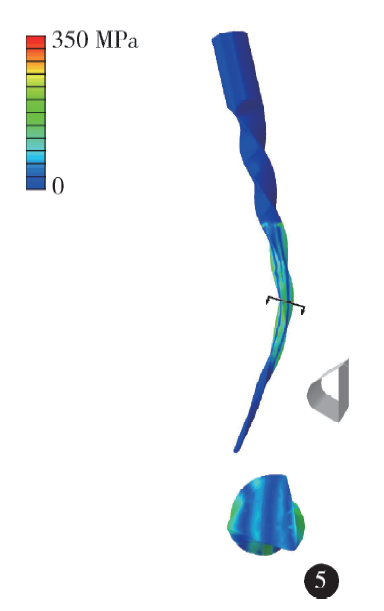

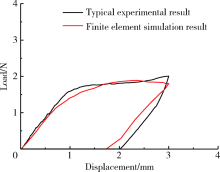

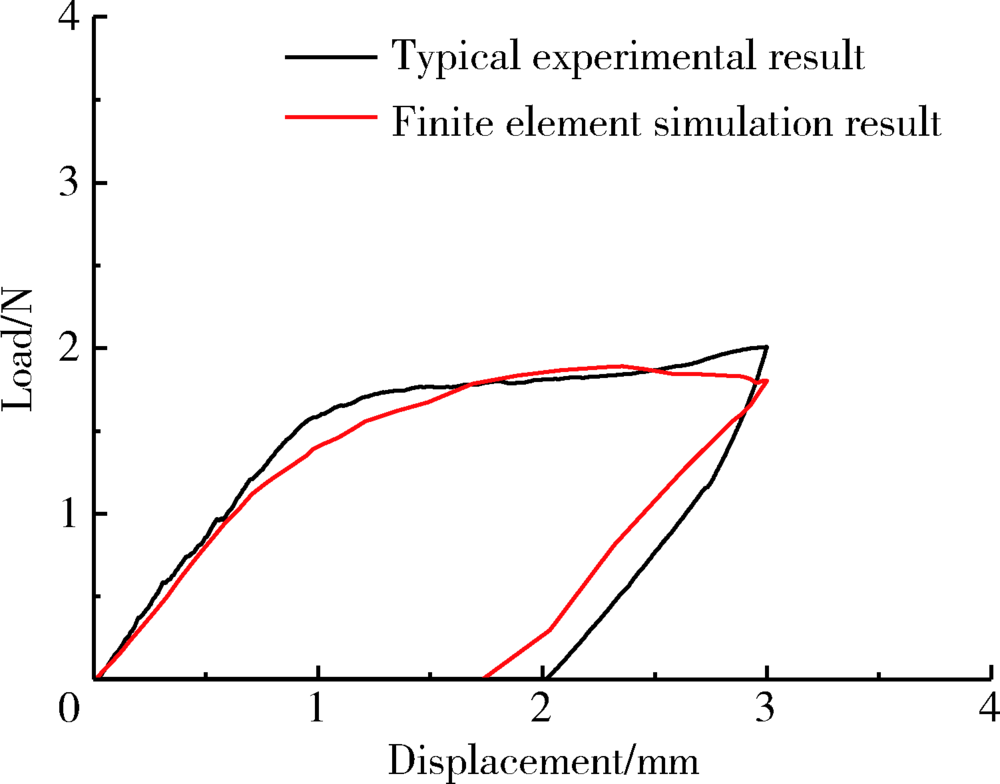

目的:通过三维有限元实验方法建立模型,用来评价控制记忆合金丝(controlled memory,CM)镍钛根管锉的弯曲性能,并将其与其他相同几何形态的镍钛合金进行比较。方法:基于逆向工程技术,将21 mm长、25#/08锥度的Hyflex NT和Hyflex CM镍钛锉通过悬臂弯曲模型在距锉尖9.5 mm处固定,力学检测仪压头在距锉尖3 mm处加载/卸载力,最大位移3 mm,得到载荷位移曲线,随后使用显微CT扫描(层间距8 μm)镍钛锉,导入ABAQUS (6.10)构建几何模型。Hyflex NT以形状记忆合金本构模型,Hyflex CM以幂硬化塑性本构模型,拟合悬臂弯曲的载荷位移曲线。结果:成功构建两个四面体单元模型,节点总数均为99 353,单元总数均为63 744。当加载位移为1 mm时,对距锉尖6.1 mm处的横截面进行应力分布观测,上、下表面受到的弯曲应力最大,并率先进入相变屈服阶段,有限元模拟能够清楚地给出锉在变形过程中的变形特点、应力分布等各种信息,与实际实验曲线拟合度好。结论:材料本构行为对于镍钛根管锉力学行为的影响十分显著,针对CM丝镍钛根管锉的特性调试参数而建立的有限元模型能够精确地捕捉镍钛根管锉各种变形过程中的特点,且与实际实验曲线拟合度好,可用于CM丝镍钛锉弯曲性能研究。

中图分类号:

- R783.1

| [1] |

Santos AL, BahiaMG, De ELC ,et al. Comparison of the mecha-nical behavior between controlled memory and superelastic nickel-titanium files via finite element analysis[J]. J Endod, 2013,39(11):1444-1447.

doi: 10.1016/j.joen.2013.07.030 pmid: 24139271 |

| [2] |

Montalvao D, Alcada FS, Braz FM , et al. Structural characterization and mechanical FE analysis of conventional and M-Wire Ni-Ti alloys used in endodontic rotary instruments[J]. Sci World J, 2014,2014:1-8.

doi: 10.1155/2014/976459 pmid: 3918393 |

| [3] |

Montalvao D, Alcada FS . Numeric comparison of the static mechanical behavior between ProFile GT and ProFile GT series X rotary nickel-titanium files[J]. J Endod, 2011,37(8):1158-1161.

doi: 10.1016/j.joen.2011.05.018 pmid: 21763913 |

| [4] |

Auricchio F, Taylor RL . Shape-memory alloys: modelling and numerical simulations of the finite-strain superelastic behavior[J]. Comput Methods Mech Engrg, 1997,143(1):175-194.

doi: 10.1016/S0045-7825(96)01147-4 |

| [5] | 徐秉业 . 应用弹塑性力学 [M]. 北京: 清华大学出版社, 1995. |

| [6] |

Santos L, López JB, Casas EB , et al. Mechanical behavior of three nickel-titanium rotary files: A comparison of numerical simulation with bending and torsion tests[J]. Mater Sci Eng C Mater Biol Appl, 2014,37(1):258-263.

doi: 10.1016/j.msec.2014.01.025 pmid: 24582247 |

| [7] |

Hou X, Yahata Y, Hayashi Y . Phase transformation behaviour and bending property of twisted nickel-titanium endodontic instruments[J]. Int Endod J, 2011,44(3):253-258.

doi: 10.1111/j.1365-2591.2010.01818.x pmid: 21219356 |

| [8] |

Pongione G, Milana V . Flexibility and resistance to cyclic fatigue of endodontic instruments made with different nickel-titanium alloys: a comparative test[J]. Ann Stomatol, 2012,3(3-4):119-122.

pmid: 23386933 |

| [9] |

Zinelis S, Eliades T, Eliades G . A metallurgical characterization of ten endodontic Ni-Ti instruments: assessing the clinical relevance of shape memory and superelastic properties of Ni-Ti endodontic instruments[J]. Int Endod J, 2010,43(2):125-134.

doi: 10.1111/j.1365-2591.2009.01651.x pmid: 20078701 |

| [10] |

Yahata Y, Yoneyama T, Hayashi Y , et al. Effect of heat treatment on transformation temperatures and bending properties of nickel-titanium endodontic instruments[J]. Int Endod J, 2010,42(7):621-626.

doi: 10.1111/j.1365-2591.2009.01563.x pmid: 19467049 |

| [11] |

Alapati SB, Brantley WA, Lijima M , et al. Metallurgical characterization of a new nickel-titanium wire for rotary endodontic instruments[J]. J Endod, 2009,35(11):1589-1593.

doi: 10.1016/j.joen.2009.08.004 pmid: 19840654 |

| [12] |

Shen Y, Coil JM, Zhou H , et al. HyFlex nickel-titanium rotary instruments after clinical use: metallurgical properties[J]. Int Endod J, 2013,46(8):720-729.

doi: 10.1111/iej.12049 pmid: 23330612 |

| [13] |

Ninan E, Berzins DW . Torsion and bending properties of shape memory and superelastic nickel-titanium rotary instruments[J]. J Endod, 2013,39(1):101-104.

doi: 10.1016/j.joen.2012.08.010 pmid: 23228266 |

| [14] |

Shen Y, Qian W, Abtin H , et al. Fatigue testing of controlled memory wire nickel-titanium rotary instruments[J]. J Endod, 2011,37(7):997-1001.

doi: 10.1016/j.joen.2011.03.023 pmid: 21689559 |

| [1] | 欧蒙恩,丁云,唐卫峰,周永胜. 基台边缘-牙冠的平台转移结构中粘接剂流动的三维有限元分析[J]. 北京大学学报(医学版), 2023, 55(3): 548-552. |

| [2] | 马珂楠,陈虎,沈妍汝,周永胜,王勇,孙玉春. 选择性激光熔化打印可摘局部义齿圆环形卡环固位力的有限元分析[J]. 北京大学学报(医学版), 2022, 54(1): 105-112. |

| [3] | 周伟,安金刚,荣起国,张益. 下颌骨颏部骨折联合双侧髁突囊内骨折致伤机制的三维有限元分析[J]. 北京大学学报(医学版), 2021, 53(5): 983-989. |

| [4] | 任爽,时会娟,张家豪,刘振龙,邵嘉艺,朱敬先,胡晓青,黄红拾,敖英芳. 前交叉韧带重建术后移植物应力的有限元分析[J]. 北京大学学报(医学版), 2021, 53(5): 865-870. |

| [5] | 姜又升,冯琳,高学军. 垫底材料弹性模量对髓腔固位冠修复后上颌前磨牙应力分布的影响[J]. 北京大学学报(医学版), 2021, 53(4): 764-769. |

| [6] | 林春平,卢松鹤,朱浚鑫,胡洪成,岳兆国,唐志辉. 个性化根形种植体的螺纹形态对周围牙槽骨应力分布影响的三维有限元分析[J]. 北京大学学报(医学版), 2019, 51(6): 1130-1137. |

| [7] | 柳大为,李晶,郭亮,荣起国,周彦恒. 舌侧矫治器关闭间隙上前牙牙周膜应力变化的三维有限元分析[J]. 北京大学学报(医学版), 2018, 50(1): 141-147. |

| [8] | 孙丽颖,郭阳,荣起国,田光磊. 舟骨骨折术后康复治疗的有限元分析[J]. 北京大学学报(医学版), 2016, 48(4): 751-封三. |

| [9] | 赵旭, 张磊, 孙健, 杨振宇,谢秋菲. 后牙种植体支持单冠牙合面高度的三维有限元力学分析[J]. 北京大学学报(医学版), 2016, 48(1): 94-100. |

| [10] | 甄敏,胡文杰,荣起国. 上颌中切牙冠根折行冠延长术并桩核冠修复的三维有限元分析[J]. 北京大学学报(医学版), 2015, 47(6): 1015-1021. |

| [11] | 周团锋, 张相皞, 王新知. 一体化计算机辅助设计与制作氧化锆桩核的三维有限元分析[J]. 北京大学学报(医学版), 2015, 47(1): 78-84. |

| [12] | 杨雪, 荣起国, 杨亚东. 附着体类型对种植支持可摘局部义齿应力分布的影响[J]. 北京大学学报(医学版), 2015, 47(1): 72-77. |

| [13] | 刘海鹰,王捷夫,朱震奇. 融合与Topping-off术对腰椎影响的有限元分析[J]. 北京大学学报(医学版), 2013, 45(5): 723-727. |

| [14] | 刘诗铭, 刘玉华, 徐军. 牙槽骨高度对上颌前磨牙桩核冠修复后应力分布的影响[J]. 北京大学学报(医学版), 2013, 45(1): 44-49. |

| [15] | 周团锋, 王新知Δ. 三种不同直径一体化计算机辅助设计与制作氧化锆全瓷桩核修复的有限元法分析[J]. 北京大学学报(医学版), 2012, 44(1): 93-97. |

|

||