北京大学学报(医学版) ›› 2019, Vol. 51 ›› Issue (1): 111-114. doi: 10.19723/j.issn.1671-167X.2019.01.020

CAD/CAM钛合金表面处理工艺联合树脂粘接剂对硬质复合树脂粘接强度和耐久性的影响

- 1. 北京大学口腔医学院·口腔医院,口腔种植科 国家口腔疾病临床医学研究中心 口腔数字化医疗技术和材料国家工程实验室 口腔数字医学北京市重点实验室,北京 100081

2. 首都医科大学附属北京口腔医院口腔种植科, 北京 100050

Effects of CAD/CAM titanium alloy surface treatment and resin luting on shear bond strength and durability of composite resin

- 1. Department of Oral Implantology, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

2. Department of Oral Implantology, Beijing Stomatological Hospital, School of Stomatology, Capital Medical University, Beijing 100050, China

摘要:

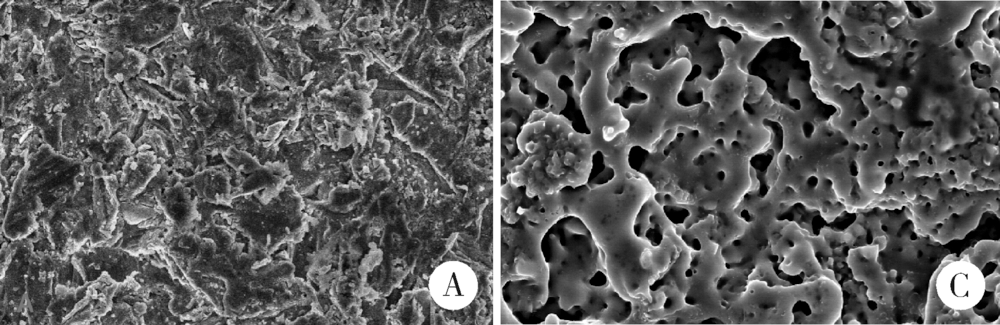

目的:研究喷砂和微弧氧化两种金属表面处理方式及树脂粘结剂对钛合金与硬质复合树脂粘结强度和耐久性的影响。方法:应用CAD/CAM技术切削出80个底面直径10 mm、高8 mm的圆柱形钛合金试件。根据表面处理方式分为两组:喷砂组(sandblasting,SB)试件表面进行Al2O3 颗粒喷砂,微弧氧化组(microarc-oxidation,MAO)试件表面处理后形成疏松多孔的陶瓷膜结构。每组内根据是否应用树脂粘结剂分为SB-resin luting-N组(不使用)、SB-resin luting-Y组(使用)、MAO-resin luting-N组(不使用)、MAO-resin luting-Y组(使用)4个亚组。试件与Cemerage硬质复合树脂粘结固化,每组的各一半测试冷热循环0次和5 000次后的粘结强度,对比分析测试结果。扫描电镜观察粘结强度试验前后钛合金试件表面形貌。结果:喷砂联合树脂粘结剂组冷热循环0次后,钛合金与硬质复合树脂的粘结强度最高(16.2±1.8) MPa;微弧氧化未联合树脂粘结剂组冷热循环5 000次后,两者的粘结强度最低(8.9±1.5) MPa,喷砂和微弧氧化未联合树脂粘结剂组冷热循环5 000次后粘结强度分别为(10.7±2.2) MPa和(8.9±1.5) MPa,相比循环0次组降低,差异有统计学意义(P=0.000和P=0.001);喷砂和微弧氧化处理联合树脂粘结剂5 000次冷热循环后粘结强度分别为(15.5±2.1) MPa和(11.7±1.3) MPa,相比循环0次组降低,但差异无统计学意义(P=0.087和P=0.234)。结论:喷砂和微弧氧化两种表面处理方式联合树脂粘结剂均可提高钛合金与硬质复合树脂的粘结强度和耐久性,以喷砂组提高更为显著;目前受微弧氧化技术参数的限制,喷砂效果优于微弧氧化。

中图分类号:

- R783.1

| [1] |

Guo CY, Tang ATH, Matinlinna JP . Insights into surface treatment methods of titanium dental implants[J]. J Adhes Sci Tech-nol, 2012,26(1/2/3):189-205.

doi: 10.1163/016942411X569390 |

| [2] |

Abduo J . Fit of CAD/CAM implant frameworks: a comprehensive review[J]. J Oral Implantlol, 2014,40(6):758-766.

doi: 10.1563/AAID-JOI-D-12-00117.1 pmid: 23009670 |

| [3] |

Molitor P, Barron V, Young T . Surface treatment of titanium for adhesive bonding to polymer composites: a review[J]. Int J Adhes, 2001,21(2):129-136.

doi: 10.1016/S0143-7496(00)00044-0 |

| [4] |

Egoshi T, Taira Y, Soeno K , et al. Effects of sandblasting, H2SO4/HCl etching, and phosphate primer application on bond strength of veneering resin composite to commercially pure titanium grade 4[J]. Dent Mater J, 2013,32(2):219-227.

doi: 10.4012/dmj.2012-261 pmid: 23538756 |

| [5] |

Yang G, Xianyi L, Bai Y , et al. The effects of current density on the phase composition and microstructure properties of micro-arc oxidation coating[J]. J Alloy Compd, 2002,345(1/2):196-200.

doi: 10.1016/S0925-8388(02)00289-X |

| [6] |

Taira Y, Yanagida H, Matsumura H , et al. Adhesive bonding of titanium with a thione-phosphate dual functional primer and self-curing luting agents[J]. Eur J Oral Implantol, 2000,108(5):456-460.

doi: 10.1034/j.1600-0722.2000.108005456.x pmid: 11037763 |

| [7] |

马志玲, 刘杰 . 钛基底表面处理对钛-树脂粘接强度的影响[J]. 国际口腔医学杂志, 2017,44(1):45-49.

doi: 10.7518/gjkq.2017.01.009 |

| [8] |

Darvell BW, Samman N, Luk WK , et al. Contamination of titanium castings by aluminium oxide blasting[J]. J Dent, 1995,23(5):319-322.

doi: 10.1016/0300-5712(94)00003-X pmid: 7560379 |

| [9] |

Ban S, Taniki T, Sato H , et al. Acid etching of titanium for bonding with veneering composite resins[J]. Dent Mater J, 2006,25(2):382.

doi: 10.4012/dmj.25.382 pmid: 16916245 |

| [10] |

Nie X, Leyland A, Matthews A . Deposition of layered bioceramic hydroxyapatite/TiO2, coatings on titanium alloys using a hybrid technique of micro-arc oxidation and electrophoresis[J]. Surf Coat Tech, 2000,125(1/2/3):407-414.

doi: 10.1016/S0257-8972(99)00612-X |

| [11] |

蒋百灵, 张菊梅, 时惠英 . 钛合金微弧氧化膜表面形貌对膜/环氧树脂结合强度的影响[J]. 中国有色金属学报, 2004,14(4):539-542.

doi: 10.3321/j.issn:1004-0609.2004.04.004 |

| [12] |

Tian J, Luo Z, Qi S , et al. Structure and antiwear behavior of micro-arc oxidized coatings on aluminum alloy[J]. Surf Coat Tech, 2002,154(1):1-7.

doi: 10.1016/S0257-8972(01)01671-1 |

| [13] |

De SG, Hennig D, Aggarwal A , et al. The use of MDP-based materials for bonding to zirconia[J]. J Prosthet Dent, 2014,112(4):895-902.

doi: 10.1016/j.prosdent.2014.01.016 pmid: 24767903 |

| [14] |

Lindgren J, Smeds J, Sjögren G . Effect of surface treatments and aging in water on bond strength to zirconia[J]. Oper Dent, 2008,33(6):675-681.

doi: 10.2341/08-12 pmid: 19051861 |

| [1] | 杨洋,浦婷婷,陈立,谭建国. 比较两种改良式印章法辅助后牙树脂牙合贴面修复的形态准确性[J]. 北京大学学报(医学版), 2021, 53(5): 977-982. |

| [2] | 李媛,林红,张铁军. 对比传统成像与数字成像对牙科复合树脂X射线阻射性的影响[J]. 北京大学学报(医学版), 2021, 53(5): 995-1001. |

| [3] | 穆海丽,田福聪,王晓燕,高学军. 玻璃体和通用型复合树脂耐磨性的临床对照研究[J]. 北京大学学报(医学版), 2021, 53(1): 120-125. |

| [4] | 于鹏,王晓燕. 填料折射率与比例对复合树脂折射率和透明度的影响[J]. 北京大学学报(医学版), 2020, 52(4): 790-793. |

| [5] | 唐仁韬,李欣海,于江利,冯琳,高学军. 复合树脂与玻璃陶瓷微拉伸粘接强度的体外研究[J]. 北京大学学报(医学版), 2020, 52(4): 755-761. |

| [6] | 郭惠杰,高承志, 林斐,刘伟,岳林. 唾液污染对复合树脂间粘接强度的影响[J]. 北京大学学报(医学版), 2017, 49(1): 96-100. |

| [7] | 林斐, 刘伟, 闫鹏, 岳林. 复合树脂间粘接的微拉伸强度研究[J]. 北京大学学报(医学版), 2015, 47(1): 124-128. |

| [8] | 蔡雪, 聂杰, 王祖华, 田洪琰, 赵莹, 王晓燕. 洞缘形态对复合树脂颜色匹配的影响[J]. 北京大学学报(医学版), 2015, 47(1): 120-123. |

| [9] | 田福聪,王晓燕,高学军. 不同粘接系统用于楔状缺损直接修复的临床观察[J]. 北京大学学报(医学版), 2014, 46(1): 58-61. |

| [10] | 袁慎坡, 林红, 潘硕, 娄丽丽, 徐永祥. Polident义齿清洁剂对义齿基托树脂性能的影响[J]. 北京大学学报(医学版), 2012, 44(6): 946-949. |

| [11] | 徐永祥, 韩建民, 林红. 自黏性流动树脂的性能研究[J]. 北京大学学报(医学版), 2012, 44(2): 303-306. |

| [12] | 高博韬, 郑刚, 林红, 徐永祥. 实时动态分析牙科光固化复合树脂固化收缩的新方法[J]. 北京大学学报(医学版), 2011, 43(6): 895-899. |

| [13] | 韩冰, 董艳梅, 王晓燕, 高学军. 光照模式对复合树脂聚合收缩率和表面硬度的影响[J]. 北京大学学报(医学版), 2011, 43(5): 770-773. |

| [14] | 赵奇*, 薛世华*, 吴艳, 王世明. 应用龈色树脂修复前牙颈部缺损的临床评价[J]. 北京大学学报(医学版), 2011, 43(1): 44-47. |

| [15] | 韩冰, 王晓燕, 高学军. 光功率密度对光固化复合树脂耐老化性能的影响[J]. 北京大学学报(医学版), 2011, 43(1): 58-61. |

|

||