北京大学学报(医学版) ›› 2022, Vol. 54 ›› Issue (1): 140-145. doi: 10.19723/j.issn.1671-167X.2022.01.022

不同材料及厚度椅旁CAD/CAM瓷贴面的边缘特征

李怡1,王丽瑜2,刘晓强1,△( ),周倜3,吕季喆1,谭建国1

),周倜3,吕季喆1,谭建国1

- 1.北京大学口腔医学院·口腔医院修复科,国家口腔医学中心,国家口腔疾病临床医学研究中心,口腔数字化医疗技术和材料国家工程实验室,北京 100081

2.南京医科大学口腔医学院,南京 210029

3.烟台市口腔医院福山分院修复科,烟台 264001

Marginal features of CAD/CAM laminate veneers with different materials and thicknesses

LI Yi1,WONG Lai U2,LIU Xiao-qiang1,△( ),ZHOU Ti3,LYU Ji-zhe1,TAN Jian-guo1

),ZHOU Ti3,LYU Ji-zhe1,TAN Jian-guo1

- 1. Department of Prosthodontics, Peking University School and Hospital of Stomatology & National Center of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology, Beijing 100081, China

2. Stomatological College of Nanjing Medical University, Nanjing 210029, China

3. Department of Prosthodontics, Fushan Clinical Division, Yantai Stomatological Hospital, Yantai 264001, Shandong, China

摘要:

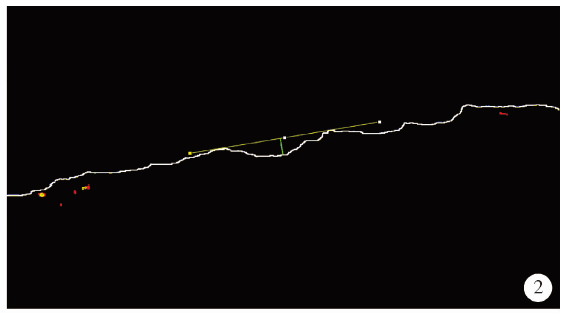

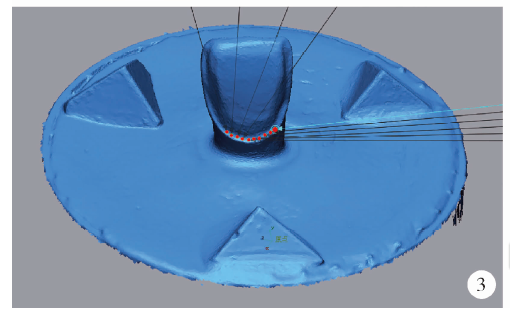

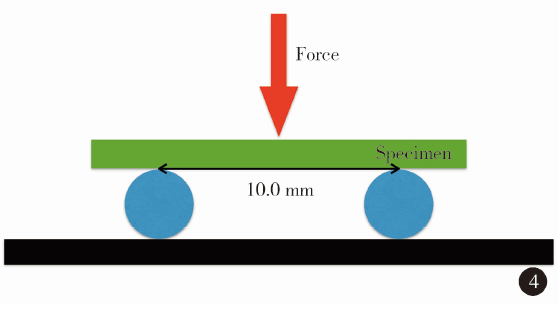

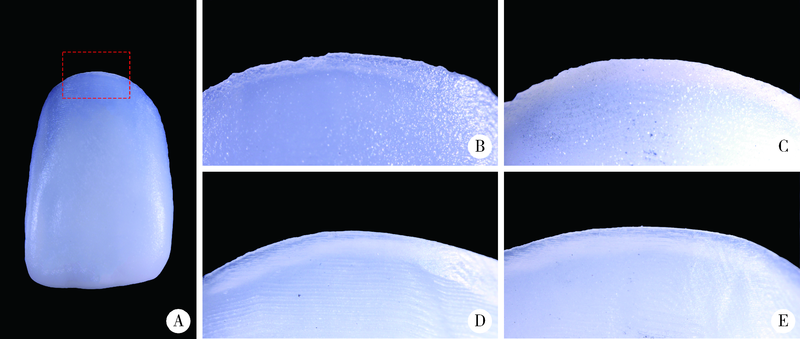

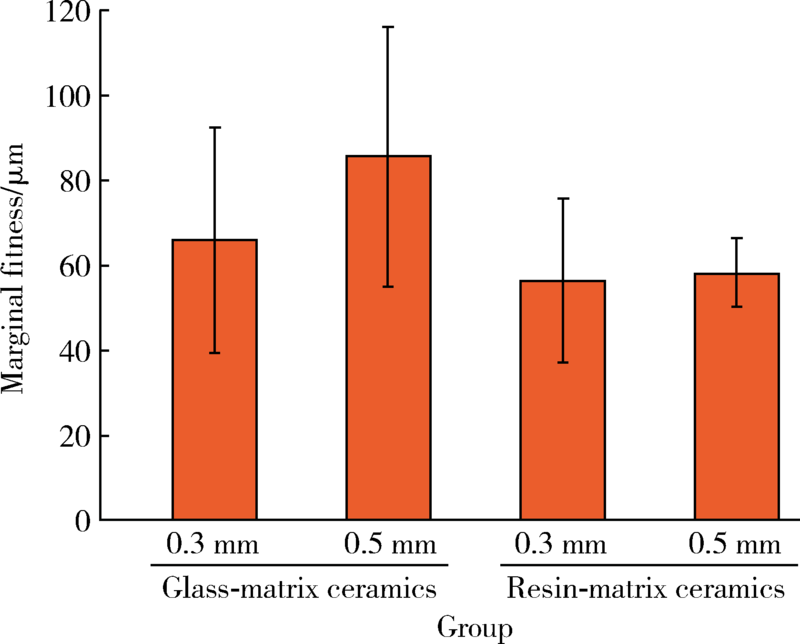

目的: 评价不同材料及厚度椅旁计算机辅助设计和计算机辅助制作(computer-aided design and computer-aided manufacturing,CAD/CAM)瓷贴面的边缘粗糙度和边缘密合度,旨在为瓷贴面的临床应用提供参考。方法: 在树脂人工牙上进行对接型瓷贴面牙体预备,利用扫描仪扫描预备体,利用椅旁切削设备CAD/CAM瓷贴面。根据陶瓷材料类型(玻璃基陶瓷和树脂基陶瓷)及贴面厚度(0.3 mm和0.5 mm)将贴面分为4组(n=9),共36个。利用体式显微镜拍摄瓷贴面边缘形貌的数码照片,在软件内测量边缘粗糙度;利用间隙检查剂和数字化扫描与测量方法评价瓷贴面的边缘密合度;同时利用万能力学试验机测试玻璃基陶瓷和树脂基陶瓷条形试件(n=20)的力学性能。结果: 厚度为0.3 mm和0.5 mm玻璃基陶瓷贴面的边缘粗糙度分别为(24.48±5.55) μm和(19.06±5.75) μm,差异有统计学意义(P<0.001);厚度为0.3 mm和0.5 mm树脂基陶瓷贴面的边缘粗糙度分别为(6.13±1.27) μm和(6.84±2.19) μm,差异无统计学意义(P>0.05);玻璃基陶瓷贴面的边缘粗糙度大于树脂基陶瓷,差异有统计学意义(P<0.001)。厚度为0.3 mm和0.5 mm玻璃基陶瓷贴面的边缘密合度分别为(66.30±26.71) μm和(85.48±30.44) μm,厚度为0.3 mm和0.5 mm树脂基陶瓷贴面的边缘密合度分别为(56.42±19.27) μm和(58.36±8.33) μm,4组间差异均无统计学意义(P>0.05)。玻璃基陶瓷的弯曲强度为(327.40±54.25) MPa,弯曲模量为(44.40±4.39) GPa,回弹模量为(1.24±0.37) MPa;树脂基陶瓷的弯曲强度为(173.71±16.61) MPa,弯曲模量为(11.88±0.51) GPa,回弹模量为(1.29±0.27) MPa;玻璃基陶瓷的弯曲强度和弯曲模量大于树脂基陶瓷,差异有统计学意义(P<0.001),但两种材料的回弹模量差异无统计学意义(P>0.05)。结论: 椅旁CAD/CAM玻璃基陶瓷贴面的边缘粗糙度大于树脂基陶瓷贴面,但二者的边缘密合度无显著差异。增加贴面厚度可降低玻璃基陶瓷贴面的边缘粗糙度,但对树脂基陶瓷贴面的边缘粗糙度无影响。

中图分类号:

- R783.1

| [1] |

Spitznagel FA, Boldt J, Gierthmuehlen PC. CAD/CAM ceramic restorative materials for natural teeth[J]. J Dent Res, 2018, 97(10):1082-1091.

doi: 10.1177/0022034518779759 pmid: 29906206 |

| [2] |

Padrós R, Giner L, Herrero-Climent M, et al. Influence of the CAD-CAM systems on the marginal accuracy and mechanical pro-perties of dental restorations[J]. Int J Env Res Pub He, 2020, 17(12):4276.

doi: 10.3390/ijerph17124276 |

| [3] |

Ruse ND, Sadoun MJ. Resin-composite blocks for dental CAD/CAM applications[J]. J Dent Res, 2014, 93(12):1232-1234.

doi: 10.1177/0022034514553976 pmid: 25344335 |

| [4] |

Zhang Y, Kelly JR. Dental ceramics for restoration and metal veneering[J]. Dent Clin North Am, 2017, 61(4):797-819.

doi: S0011-8532(17)30071-X pmid: 28886769 |

| [5] | 中华口腔医学会口腔美学专业委员会, 中华口腔医学会口腔材料专业委员会. 全瓷美学修复材料临床应用专家共识[J]. 中华口腔医学志, 2019, 54(12):825-828. |

| [6] |

Lambert H, Durand JC, Jacquot B, et al. Dental biomaterials for chairside CAD/CAM: State of the art[J]. J Adv Prosthodont, 2017, 9(6):486-495.

doi: 10.4047/jap.2017.9.6.486 pmid: 29279770 |

| [7] |

Yamaguchi S, Kani R, Kawakami K, et al. Fatigue behavior and crack initiation of CAD/CAM resin composite molar crowns[J]. Dent Mater, 2018, 34(10):1578-1584.

doi: S0109-5641(18)30331-2 pmid: 30049596 |

| [8] |

Gracis S, Thompson VP, Ferencz JL, et al. A new classification system for all-ceramic and ceramic-like restorative materials[J]. Int J Prosthodont, 2015, 28(3):227-235.

doi: 10.11607/ijp.4244 |

| [9] |

Chavali R, Nejat AH, Lawson NC. Machinability of CAD-CAM materials[J]. J Prosthet Dent, 2017, 118(2):194-199.

doi: 10.1016/j.prosdent.2016.09.022 |

| [10] | Alqahtani F. Marginal fit of all-ceramic crowns fabricated using two extraoral CAD/CAM systems in comparison with the conventional technique[J]. Clin Cosmet Inv Dent, 2017(9):13-18. |

| [11] |

Bindl A, Mörmann WH. Marginal and internal fit of all-ceramic CAD/CAM crown-copings on chamfer preparations[J]. J Oral Rehabil, 2005, 32(6):441-447.

pmid: 15899023 |

| [12] |

Memari Y, Mohajerfar M, Armin A, et al. Marginal adaptation of CAD/CAM all-ceramic crowns made by different impression methods: A literature review[J]. J Prosthodont, 2019, 28(2):536-544.

doi: 10.1111/jopr.2019.28.issue-5 |

| [13] |

Contrepois M, Soenen A, Bartala, et al. Marginal adaptation of ceramic crowns: A systematic review[J]. J Prosthet Dent, 2013, 110(6):447-454.

doi: 10.1016/j.prosdent.2013.08.003 pmid: 24120071 |

| [14] |

Awada A, Nathanson D. Mechanical properties of resin-ceramic CAD/CAM restorative materials[J]. J Prosthet Dent, 2015, 114(4):587-593.

doi: 10.1016/j.prosdent.2015.04.016 |

| [15] | 刘晓强, 谭建国. 一步一步做好微创修复的贴面牙体预备[J]. 中华口腔医学杂志, 2021, 56(3):306-310. |

| [16] | Lee H, Kim HS, Noh K, et al. A simplified method for evaluating the 3-dimensional cement space of dental prostheses by using a digital scanner[J]. J Prosthet Dent, 2017, 118(5):584-586. |

| [17] |

Yang Y, Yang Z, Zhou J, et al. Effect of tooth preparation design on marginal adaptation of composite resin CAD-CAM onlays[J]. J Prosthet Dent, 2020, 124(1):88-93.

doi: S0022-3913(19)30540-2 pmid: 31672425 |

| [18] |

Awad D, Stawarczyk B, Liebermann A, et al. Translucency of esthetic dental restorative CAD/CAM materials and composite resins with respect to thickness and surface roughness[J]. J Prosthet Dent, 2015, 113(6):534-540.

doi: 10.1016/j.prosdent.2014.12.003 |

| [19] | 李德利, 谭建国. 一步一步做好全瓷修复体抛光[J]. 中华口腔医学杂志, 2021, 56(4):396-400. |

| [20] |

Wright MD, Masri R, Driscoll CF, et al. Comparison of three systems for the polishing of an ultra-low fusing dental porcelain[J]. J Prosthet Dent, 2004, 92(5):486-490.

doi: 10.1016/j.prosdent.2004.07.021 |

| [21] |

Freire Y, Gonzalo E, Lopez-Suarez C, et al. Evaluation of the marginal fit of monolithic crowns fabricated by direct and indirect digitization[J]. J Prosthodont Res, 2021, 65(3):291-297.

doi: 10.2186/jpr.JPR_D_20_00003 |

| [22] |

Dureja I, Yadav B, Malhotra P, et al. A comparative evaluation of vertical marginal fit of provisional crowns fabricated by computer-aided design/computer-aided manufacturing technique and direct (intraoral technique) and flexural strength of the materials: An in vitro study[J]. J Indian Prosthodont Soc, 2018, 18(4):314-320.

doi: 10.4103/jips.jips_306_17 |

| [23] |

Papadiochou S, Pissiotis AL. Marginal adaptation and CAD-CAM technology: A systematic review of restorative material and fabrication techniques[J]. J Prosthet Dent, 2018, 119(4):545-551.

doi: S0022-3913(17)30488-2 pmid: 28967399 |

| [24] |

Schaefer O, Watts DC, Sigusch BW, et al. Marginal and internal fit of pressed lithium disilicate partial crowns in vitro: A three-dimensional analysis of accuracy and reproducibility[J]. Dent Mater, 2012, 28(3):320-326.

doi: 10.1016/j.dental.2011.12.008 pmid: 22265824 |

| [25] | 林红. 口腔材料学[M]. 2版. 北京: 北京大学医学出版社, 2013: 12-13. |

| [1] | 郑佳佳,杨雪,温泉,付元,邵校,丁美丽. 生物活性陶瓷iRoot BP Plus®在儿童年轻恒前牙复杂冠折牙髓切断术中的应用[J]. 北京大学学报(医学版), 2024, 56(1): 179-184. |

| [2] | 徐心雨,吴灵,宋凤岐,李自力,张益,刘筱菁. 基于下颌运动轨迹的正颌外科术中下颌骨髁突定位方法及初步精度验证[J]. 北京大学学报(医学版), 2024, 56(1): 57-65. |

| [3] | 李穗,马雯洁,王时敏,丁茜,孙瑶,张磊. 上前牙种植单冠修复体切导的数字化设计正确度[J]. 北京大学学报(医学版), 2024, 56(1): 81-87. |

| [4] | 雍颹,钱锟,朱文昊,赵晓一,刘畅,潘洁. 成年恒牙牙髓切断后牙髓钙化的X线片评价[J]. 北京大学学报(医学版), 2023, 55(1): 88-93. |

| [5] | 李伟伟,陈虎,王勇,孙玉春. 氧化锆陶瓷表面硅锂喷涂层的摩擦磨损性能[J]. 北京大学学报(医学版), 2023, 55(1): 94-100. |

| [6] | 王爽,彭楚芳,刘鹤. 新型生物陶瓷材料用于乳磨牙牙髓切断术的临床疗效[J]. 北京大学学报(医学版), 2022, 54(6): 1196-1201. |

| [7] | 罗昊,田福聪,王晓燕. 不同椅旁可切削修复材料序列抛光时间及表面粗糙度与光泽度的比较[J]. 北京大学学报(医学版), 2022, 54(3): 565-571. |

| [8] | 冯莎蔚,国慧,王勇,赵一姣,刘鹤. 乳牙数字化参考牙冠模型的初步构建[J]. 北京大学学报(医学版), 2022, 54(2): 327-334. |

| [9] | 钱锟,潘洁,朱文昊,赵晓一,刘畅,雍颹. 两种硅酸钙类材料用于成熟恒牙牙髓切断术的临床效果[J]. 北京大学学报(医学版), 2022, 54(1): 113-118. |

| [10] | 邱淑婷,朱玉佳,王时敏,王飞龙,叶红强,赵一姣,刘云松,王勇,周永胜. 姿势微笑位口唇对称参考平面的数字化构建及初步应用验证[J]. 北京大学学报(医学版), 2022, 54(1): 193-199. |

| [11] | 李智,徐永祥,包旭东,王晓燕. 垫底树脂和固位深度对树脂基纳米陶瓷髓腔固位冠修复磨牙抗折性能的影响[J]. 北京大学学报(医学版), 2022, 54(1): 95-99. |

| [12] | 徐啸翔,曹烨,赵一姣,贾璐,谢秋菲. 数字化个齿托盘制取下颌全牙列全冠预备体印模的体外评价[J]. 北京大学学报(医学版), 2021, 53(1): 54-61. |

| [13] | 岳兆国,张海东,杨静文,侯建霞. 数字化评估CAD/CAM个性化基台与成品基台影响粘接剂残留的体外研究[J]. 北京大学学报(医学版), 2021, 53(1): 69-75. |

| [14] | 李峥,柳玉树,王时敏,张瑞,贾璐,叶红强,胡文杰,赵文艳,刘云松,周永胜. 数字化方法复制暂时修复体牙合面形态在重度磨耗病例中的应用[J]. 北京大学学报(医学版), 2021, 53(1): 62-68. |

| [15] | 房硕博,杨广聚,康艳凤,孙玉春,谢秋菲. 数字化辅助确定再定位牙合垫颌位方法的探索和精度评价[J]. 北京大学学报(医学版), 2021, 53(1): 76-82. |

|

||