北京大学学报(医学版) ›› 2019, Vol. 51 ›› Issue (1): 93-99. doi: 10.19723/j.issn.1671-167X.2019.01.017

不同加工方法及材料制作部分贴面的边缘形貌分析

王睿捷1,刘敏1,宋丹阳1,杨随1,王乔2,王磊1,△( ),冯海兰1,△(

),冯海兰1,△( )

)

- 1. 北京大学口腔医学院·口腔医院, 修复科, 北京 100081

2. 北京大学口腔医学院·口腔医院, 义齿加工中心 国家口腔疾病临床医学研究中心 口腔数字化医疗技术和材料国家工程实验室 口腔数字医学北京市重点实验室国家工程实验室, 北京 100081

Analysis of edge morphology of partial veneers made by different processing techniques and materials

Rui-jie WANG1,Min LIU1,Dan-yang SONG1,Sui YANG1,Qiao WANG2,Lei WANG1,△( ),Hai-lan FENG1,△(

),Hai-lan FENG1,△( )

)

- 1. Department of Prosthodontics, Beijing 100081, China

2. Dental Laboratory, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

摘要:

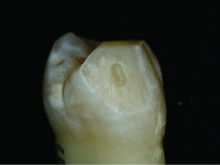

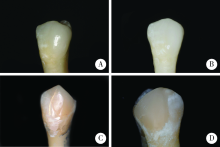

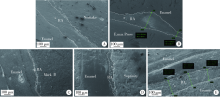

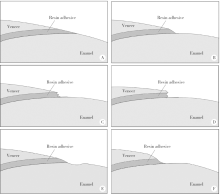

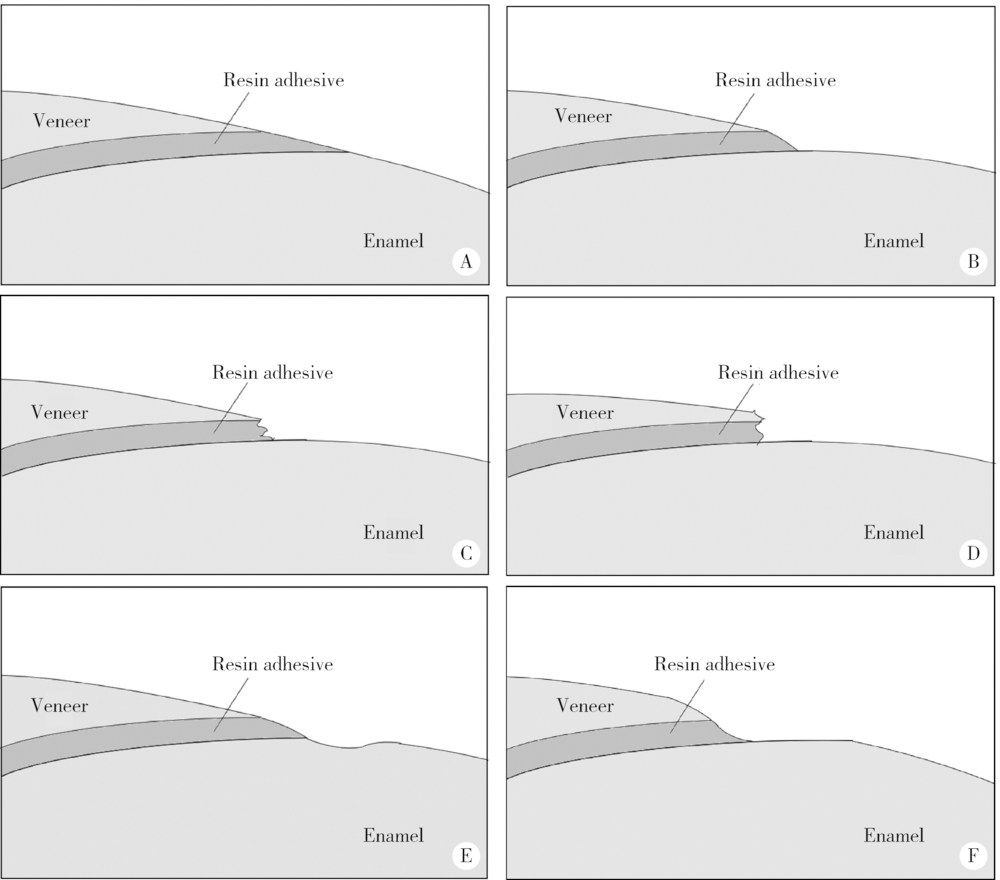

目的:比较采用粉浆堆塑工艺、热压铸造工艺及计算机辅助设计/计算机辅助制造(computer aided design/computer aided manufacturing,CAD/CAM)技术制作的不同材料部分贴面的边缘形貌。方法:选择无明显磨耗、龋坏,表面釉质光滑完整的人前磨牙30颗,随机分为5组,每组6颗,分别采用耐火代型粉浆堆塑工艺制作Noritake ?长石质烤瓷部分贴面,热压铸造工艺制作IPS E.max Press部分贴面,CAD/CAM技术制作VITA Mark Ⅱ、VITA Supri-nity、VITA Enamic部分贴面。部分贴面试件粘接完成后,按照临床步骤进行边缘修整及抛光,获得在离体牙上粘接完成的部分贴面。通过肉眼观察、扫描电镜及色散能谱,记录并分析部分贴面边缘微观形貌及粘接剂暴露宽度。结果:不同加工方式及材料的部分贴面在粘接后经过修整、抛光,可获得肉眼可见的较光滑的材料表面及菲薄的刃状边缘。Noritake烤瓷组边缘较粗糙,粘接剂带状暴露量为(106.00±9.17) μm;E.max Press组边缘较平整,粘接剂暴露量为(138.33±20.59) μm;Enamic组边缘平滑,粘接剂暴露宽度较大,为(186.00±5.66) μm;Mark Ⅱ组与Suprinity组边缘虽有粗糙不平,但粘接剂暴露较少,分别为(50.67±7.51) μm及(65.67±17.90) μm;除Mark Ⅱ组与Suprinity组外,其余各组间差异均有统计学意义。结论:不同加工方法及材料制作的部分贴面,经过粘接、修整及抛光后,均可获得刃状边缘,但各组粘接剂有不同程度暴露,暴露量大小为Mark Ⅱ组/Suprinity组

中图分类号:

- R783.3

| [1] |

Gurel G . Porcelain laminate veneers: minimal tooth preparation by design[J]. Dent Clin North Am, 2007,51(2):419-431.

doi: 10.1016/j.cden.2007.03.007 pmid: 17532920 |

| [2] |

刘峰 . 微创和无创瓷贴面修复的适应范围[J]. 口腔颌面修复学杂志, 2016,17(6):321-324.

doi: 10.3969/j.issn.1009-3761.2016.06.001 |

| [3] |

D’Arcangelo C, Vadini M, D’Amario M , et al. Protocol for a new concept of no-prep ultrathin ceramic veneers[J]. J Esthet Restor Dent, 2018,30(3):173-179.

doi: 10.1111/jerd.12351 pmid: 29139209 |

| [4] |

Farias-Neto A, Gomes EM, Sánchez-Ayala A , et al. Esthetic rehabilitation of the smile with no-prep porcelain laminates and partial veneers[J]. Case Rep Dent, 2015,2015:452765.

doi: 10.1155/2015/452765 pmid: 4628695 |

| [5] |

Vadini M, D’Amario M, De Angelis F , et al. No-prep rehabilitation of fractured maxillary incisors with partial veneers[J]. J Esthet Restor Dent, 2016,28(6):351-358.

doi: 10.1111/jerd.12229 pmid: 27354182 |

| [6] | 周玉 . 陶瓷材料学[M]. 2版.北京: 科学出版社, 2004. |

| [7] |

Vanlioglu BA, Kulak-Ozkan Y . Minimally invasive veneers: current state of the art[J]. Clin Cosmet Investig Dent, 2014(6):101-107.

doi: 10.2147/CCIDE.S53209 pmid: 25506248 |

| [8] |

刘峰, 师晓蕊, 李祎 , 等. 微创全瓷贴面修复临床应用初探[J]. 中华口腔医学杂志, 2012,47(10):614-617.

doi: 10.3760/cma.j.issn.1002-0098.2012.10.009 |

| [9] |

Gresnigt M, Ozcan M . Esthetic rehabilitation of anterior teeth with porcelain laminates and sectional veneers[J]. J Can Dent Assoc, 2011,77:b143.

doi: 10.5167/uzh-58750 pmid: 22067068 |

| [10] |

Sulik WD, Plekavich EJ . Surface finishing of dental porcelain[J]. J Prosthet Dent, 1981,46(2):217-221.

doi: 10.1016/0022-3913(81)90312-7 pmid: 6944487 |

| [11] |

Stappert CF, Ozden U, Gerds T , et al. Longevity and failure load of ceramic veneers with different preparation designs after exposure to masticatory simulation[J]. J Prosthet Dent, 2005,94(2):132-139.

doi: 10.1016/j.prosdent.2005.05.023 pmid: 16046967 |

| [12] |

Magne P, Versluis A, Douglas WH . Effect of luting composite shrinkage and thermal loads on the stress distribution in porcelain laminate veneers[J]. J Prosthet Dent, 1999,81(3):335-344.

doi: 10.1016/S0022-3913(99)70278-7 |

| [13] |

Ghaffari T, Hamedi-Rad F, Fakhrzadeh V . Marginal adaptation of Spinell InCeram and feldspathic porcelain laminate veneers[J]. Dent Res J (Isfahan), 2016,13(3):239-244.

doi: 10.4103/1735-3327.182183 pmid: 4878208 |

| [14] |

Karagozoglu I, Toksavul S, Toman M . 3D quantification of clinical marginal and internal gap of porcelain laminate veneers with minimal and without tooth preparation and 2-year clinical evaluation[J]. Quintessence Int, 2016,47(6):461-471.

doi: 10.3290/j.qi.a35700 pmid: 26949761 |

| [15] |

Zhi L, Bortolotto T, Krejci I . Comparative in vitro wear resistance of CAD/CAM composite resin and ceramic materials[J]. J Prosthet Dent, 2016,115(2):199-202.

doi: 10.1016/j.prosdent.2015.07.011 |

| [16] |

Pfeilschifter M, Preis V, Behr M , et al. Edge strength of CAD/CAM materials[J]. J Dent, 2018,74:95-100.

doi: 10.1016/j.jdent.2018.05.004 pmid: 29777736 |

| [17] |

Ganapathy D, Sathyamoorthy A, Ranganathan H , et al. Effect of resin bonded luting agents influencing marginal discrepancy in all ceramic complete veneer crowns[J]. J Clin Diagn Res, 2016,10(12):C67-C70.

doi: 10.1111/crj.12187 pmid: 25043510 |

| [1] | 徐心雨,吴灵,宋凤岐,李自力,张益,刘筱菁. 基于下颌运动轨迹的正颌外科术中下颌骨髁突定位方法及初步精度验证[J]. 北京大学学报(医学版), 2024, 56(1): 57-65. |

| [2] | 李穗,马雯洁,王时敏,丁茜,孙瑶,张磊. 上前牙种植单冠修复体切导的数字化设计正确度[J]. 北京大学学报(医学版), 2024, 56(1): 81-87. |

| [3] | 罗昊,田福聪,王晓燕. 不同椅旁可切削修复材料序列抛光时间及表面粗糙度与光泽度的比较[J]. 北京大学学报(医学版), 2022, 54(3): 565-571. |

| [4] | 冯莎蔚,国慧,王勇,赵一姣,刘鹤. 乳牙数字化参考牙冠模型的初步构建[J]. 北京大学学报(医学版), 2022, 54(2): 327-334. |

| [5] | 李怡,王丽瑜,刘晓强,周倜,吕季喆,谭建国. 不同材料及厚度椅旁CAD/CAM瓷贴面的边缘特征[J]. 北京大学学报(医学版), 2022, 54(1): 140-145. |

| [6] | 邱淑婷,朱玉佳,王时敏,王飞龙,叶红强,赵一姣,刘云松,王勇,周永胜. 姿势微笑位口唇对称参考平面的数字化构建及初步应用验证[J]. 北京大学学报(医学版), 2022, 54(1): 193-199. |

| [7] | 徐啸翔,曹烨,赵一姣,贾璐,谢秋菲. 数字化个齿托盘制取下颌全牙列全冠预备体印模的体外评价[J]. 北京大学学报(医学版), 2021, 53(1): 54-61. |

| [8] | 岳兆国,张海东,杨静文,侯建霞. 数字化评估CAD/CAM个性化基台与成品基台影响粘接剂残留的体外研究[J]. 北京大学学报(医学版), 2021, 53(1): 69-75. |

| [9] | 李峥,柳玉树,王时敏,张瑞,贾璐,叶红强,胡文杰,赵文艳,刘云松,周永胜. 数字化方法复制暂时修复体牙合面形态在重度磨耗病例中的应用[J]. 北京大学学报(医学版), 2021, 53(1): 62-68. |

| [10] | 房硕博,杨广聚,康艳凤,孙玉春,谢秋菲. 数字化辅助确定再定位牙合垫颌位方法的探索和精度评价[J]. 北京大学学报(医学版), 2021, 53(1): 76-82. |

| [11] | 罗佳,张宇,崔宏燕,祝宁,沈惠丹,邸萍,林野. 锥度固位结合数字化技术在后牙连续多牙种植即刻修复中的应用[J]. 北京大学学报(医学版), 2020, 52(5): 964-970. |

| [12] | 魏菱,邹东,陈虎,潘韶霞,孙玉春,周永胜. 一种数字化全口义齿的临床疗效评价[J]. 北京大学学报(医学版), 2020, 52(4): 762-770. |

| [13] | 孙玉春,王勇,邓珂慧,陈虎,李伟伟,赵一姣,潘韶霞,叶红强,周永胜. 功能易适数字化全口义齿的自主创新研发[J]. 北京大学学报(医学版), 2020, 52(2): 390-394. |

| [14] | 游浪,邓珂慧,李伟伟,赵一姣,孙玉春,周永胜. 无牙颌患者鼻唇角变化侧面观的视觉敏感阈值[J]. 北京大学学报(医学版), 2020, 52(1): 107-112. |

| [15] | 陈硕,贺洋,安金刚,张益. 计算机辅助设计虚拟颌位在儿童颞下颌关节强直合并颌骨畸形同期矫治中的应用[J]. 北京大学学报(医学版), 2019, 51(5): 954-958. |

|

||