北京大学学报(医学版) ›› 2021, Vol. 53 ›› Issue (2): 406-412. doi: 10.19723/j.issn.1671-167X.2021.02.029

可摘局部义齿适合性方法的评价

尹祯敏1,王子轩1,陈俊锴1,孙玉春2,刘云松1,叶红强1,Δ( ),周永胜1,Δ(

),周永胜1,Δ( )

)

- 1.修复科, 北京大学口腔医学院·口腔医院, 国家口腔疾病临床医学研究中心 口腔数字化医疗技术和材料国家工程实验室 口腔数字医学北京市重点实验室, 北京 100081

2.口腔医学数字化研究中心, 北京大学口腔医学院·口腔医院, 国家口腔疾病临床医学研究中心 口腔数字化医疗技术和材料国家工程实验室 口腔数字医学北京市重点实验室, 北京 100081

Evaluation of methods for fitness of removable partial denture

YOON Jung-min1,WANG Zi-xuan1,CHAN Chon-kai1,SUN Yu-chun2,LIU Yun-song1,YE Hong-qiang1,Δ( ),ZHOU Yong-sheng1,Δ(

),ZHOU Yong-sheng1,Δ( )

)

- 1. Department of Prosthodontics, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

2. Center for Digital Dentistry, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

摘要:

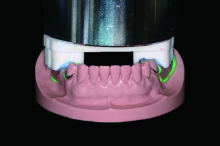

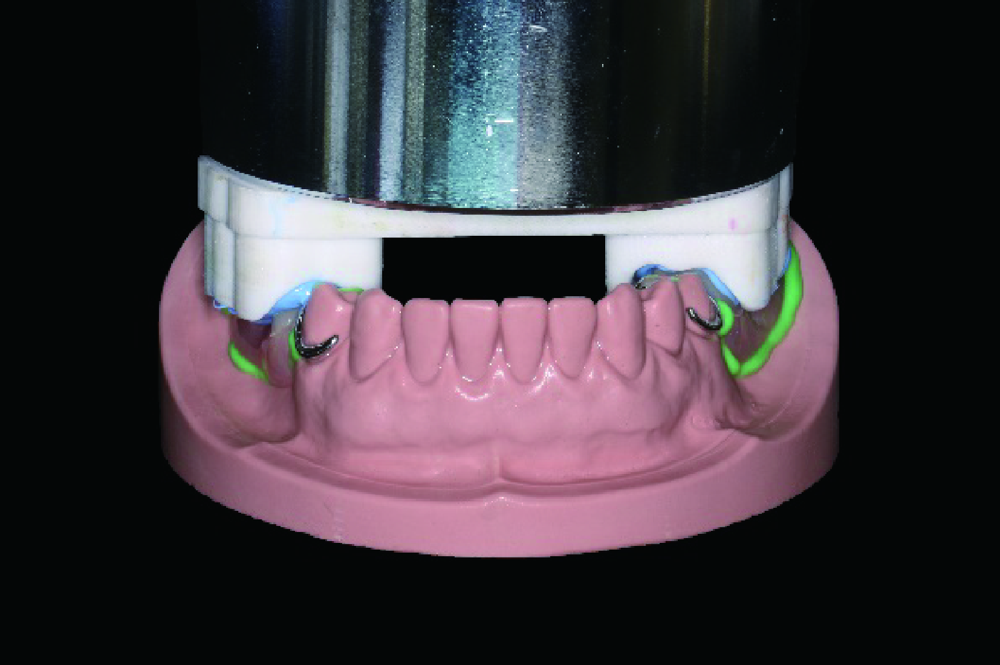

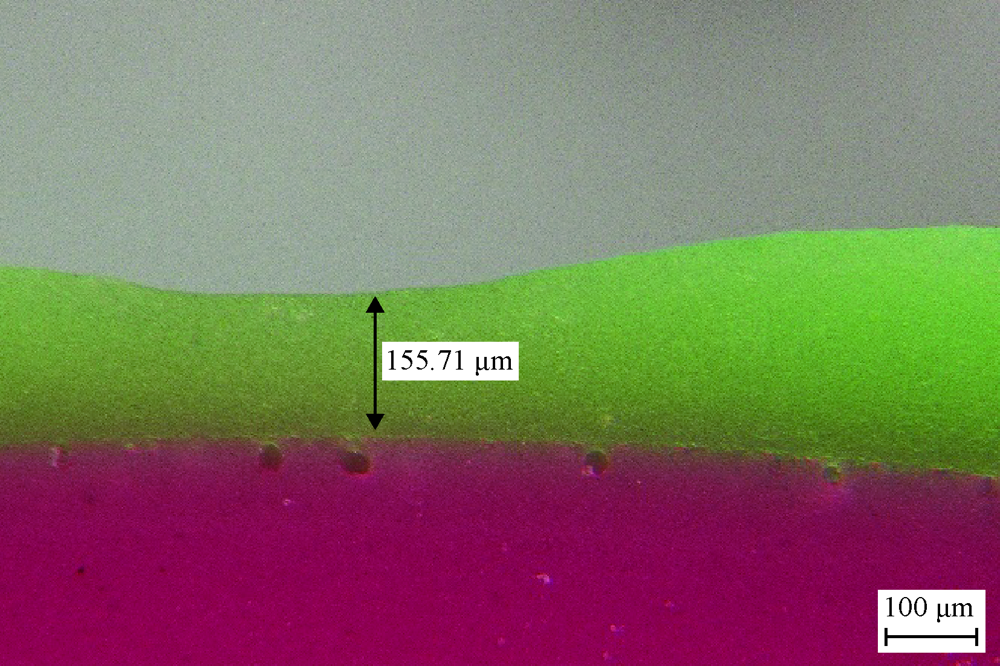

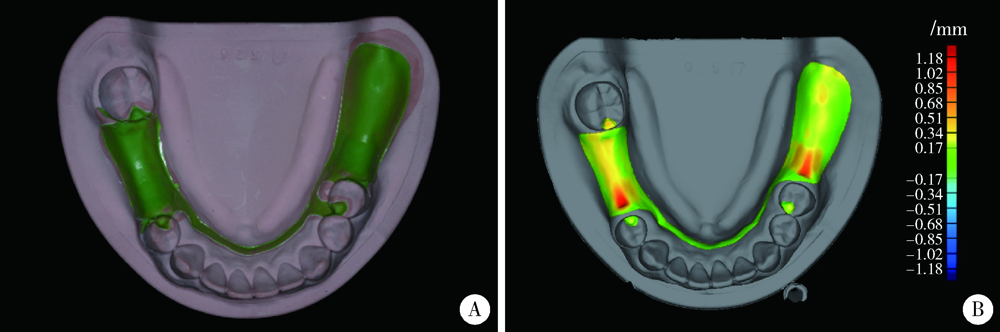

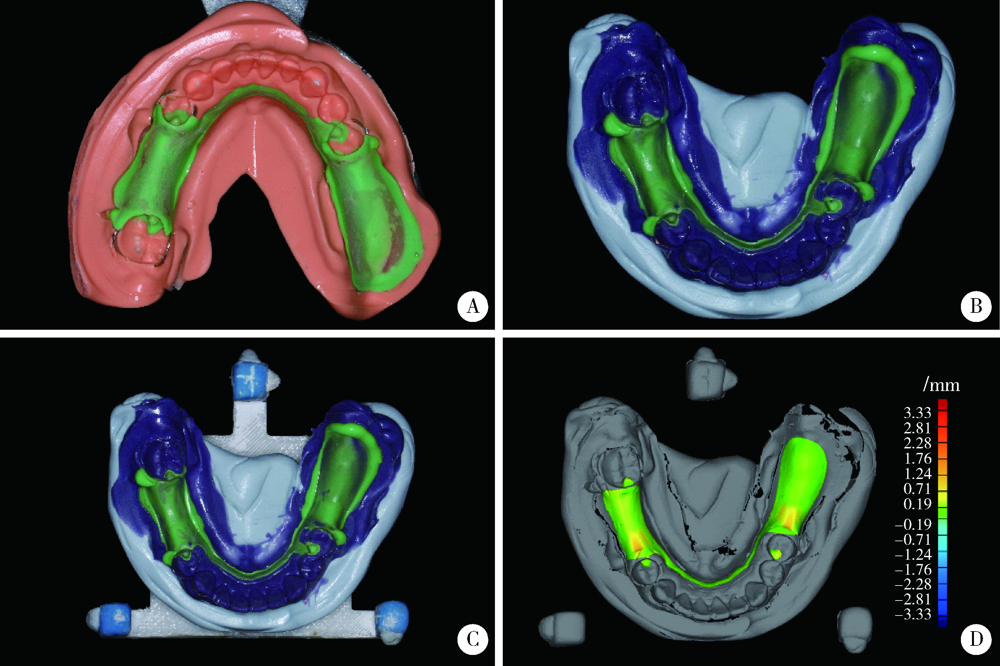

目的: 评价可摘局部义齿(removable partial denture, RPD)适合性的三种方法的异同及适应证。方法: 在下颌牙列缺损石膏模型上制作RPD,用硅橡胶印模材复制RPD与模型表面的间隙形成硅橡胶薄膜样本。在RPD各组件处的薄膜样本上,用硅橡胶膜切片测量法并选择不同数量的测量点测量获得薄膜平均厚度,再用单因素方差分析和独立样本t检验比较基托、大连接体、牙合支托处测量点数量不同对测量结果的影响。采用硅橡胶膜切片测量法、石膏模型三维分析法和翻制模型三维分析法测量RPD各组件处硅橡胶薄膜的厚度,用单因素方差分析比较三种方法的测量结果差异是否有统计学意义。结果: 硅橡胶膜切片测量法选取测量点数量不同测得的基托和大连接体处硅橡胶薄膜的平均厚度差异有统计学意义(P<0.05),牙合支托处硅橡胶薄膜的平均厚度差异无统计学意义(P>0.05)。三种评价方法测得的RPD各组件和总体的硅橡胶薄膜厚度差异均有统计学意义(P<0.01),多重比较表明,石膏模型三维分析法和翻制模型三维分析法的测量结果较硅橡胶膜切片测量法的薄(P<0.05),石膏模型三维分析法和翻制模型三维分析法测量的硅橡胶薄膜厚度差异无统计学意义(P>0.05)。结论: 硅橡胶膜切片测量法的测量结果受测量点数量影响,其测量结果可靠性较差;石膏模型三维分析法、翻制模型三维分析法较硅橡胶膜切片测量法能更全面、有效地评价RPD的适合性,石膏模型三维分析法适用于体外评价,翻制模型三维分析法适用于体内评价。

中图分类号:

- R783.4

| [1] | 冯海兰. 口腔修复学[M]. 2版. 北京: 北京大学医学出版社, 2013: 135-136. |

| [2] | 刘一帆, 王伟娜, 于海, 等. 选择性激光熔覆(SLM)钛合金可摘局部义齿支架的适合性研究[J]. 实用口腔医学杂志, 2017,33(3):302-305. |

| [3] |

Keltjens HM, Mulder J, Kayser AF, et al. Fit of direct retainers in removable partial dentures after 8 years of use[J]. J Oral Rehabil, 1997,24(2):138-142.

pmid: 9061623 |

| [4] | 吴琳, 吕培军, 王勇, 等. 可摘局部义齿支架铸型的计算机辅助设计与制作[J]. 中华口腔医学杂志, 2006,41(7):432-435. |

| [5] |

Frank RP, Brudvik JS, Leroux B, et al. Relationship between the standards of removable partial denture construction, clinical acceptability, and patient satisfaction[J]. J Prosthet Dent, 2000,83(5):521-527.

pmid: 10793382 |

| [6] | Hu F, Pei Z, Wen Y. Using intraoral scanning technology for three-dimensional printing of kennedy class Ⅰ removable partial denture metal framework: a clinical report[J]. J Prosthodont, 2019,28(2):473-476. |

| [7] |

Dunham D, Brudvik JS, Morris WJ, et al. A clinical investigation of the fit of removable partial dental prosjournal clasp assemblies[J]. J Prosthet Dent, 2006,95(4):323-326.

pmid: 16616131 |

| [8] |

Lee JW, Park JM, Park EJ, et al. Accuracy of a digital removable partial denture fabricated by casting a rapid prototyped pattern: A clinical study[J]. J Prosthet Dent, 2017,118(4):468-474.

pmid: 28389024 |

| [9] |

Torii M, Nakata T, Takahashi K, et al. Fitness and retentive force of cobalt-chromium alloy clasps fabricated with repeated laser sintering and milling[J]. J Prosthodont Res, 2018,62(3):342-346.

pmid: 29428170 |

| [10] |

Viswambaran M, Sundaram RK. Effect of storage time and framework design on the accuracy of maxillary cobalt-chromium cast removable partial dentures[J]. Contemp Clin Dent, 2015,6(4):471-476.

pmid: 26681850 |

| [11] |

Ye H, Ning J, Li M, et al. Preliminary clinical application of removable partial denture frameworks fabricated using computer-aided design and rapid prototyping techniques[J]. Int J Prosthodont, 2017,30(4):348-353.

pmid: 28697204 |

| [12] |

Arnold C, Hey J, Schweyen R, et al. Accuracy of CAD-CAM-fabricated removable partial dentures[J]. J Prosthet Dent, 2018,119(4):586-592.

pmid: 28709674 |

| [13] |

Lee WS, Lee DH, Lee KB. Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system[J]. J Adv Prosthodont, 2017,9(4):265-270.

pmid: 28874993 |

| [14] | Kim DY, Kim JH, Kim HY, et al. Comparison and evaluation of marginal and internal gaps in cobalt-chromium alloy copings fabricated using subtractive and additive manufacturing[J]. J Pros-thodont Res, 2018,62(1):56-64. |

| [15] |

Ye H, Li X, Wang G, et al. A Novel computer-aided design/computer-assisted manufacture method for one-piece removable partial denture and evaluation of fit[J]. Int J Prosthodont, 2018,31(2):149-151.

pmid: 29448267 |

| [16] |

Groten M, Axmann D, Probster L, et al. Determination of the minimum number of marginal gap measurements required for practical in vitro testing[J]. J Prosthet Dent, 2000,83(1):40-49.

pmid: 10633021 |

| [17] |

Liu Y, Ye H, Wang Y, et al. Three-dimensional analysis of internal adaptations of crowns cast from resin patterns fabricated using computer-aided design/computer-assisted manufacturing technologies[J]. Int J Prosthodont, 2018,31(4):386-393.

pmid: 29772034 |

| [18] |

Kim KB, Kim JH, Kim WC, et al. Three-dimensional evaluation of gaps associated with fixed dental prostheses fabricated with new technologies[J]. J Prosthet Dent, 2014,112(6):1432-1436.

pmid: 25218032 |

| [19] | 李欣欣, 柳玉树, 孙玉春, 等. 计算机辅助设计与制作一体化聚醚醚酮可摘局部义齿不同形态组件的适合性评价[J]. 北京大学学报(医学版), 2019,51(2):335-339 |

| [20] |

Anadioti E, Aquilino SA, Gratton DG, et al. 3D and 2D marginal fit of pressed and CAD/CAM lithium disilicate crowns made from digital and conventional impressions[J]. J Prosthodont, 2014,23(8):610-617.

pmid: 24995593 |

| [1] | 周团锋,杨雪,王睿捷,程明轩,张华,韦金奇. 数字化制作简易口内哥特式弓在全口义齿修复正中关系确定中的应用[J]. 北京大学学报(医学版), 2023, 55(1): 101-107. |

| [2] | 孙玉春,郭雨晴,陈虎,邓珂慧,李伟伟. 口腔精准仿生修复技术的自主创新研发与转化[J]. 北京大学学报(医学版), 2022, 54(1): 7-12. |

| [3] | 李怡,王丽瑜,刘晓强,周倜,吕季喆,谭建国. 不同材料及厚度椅旁CAD/CAM瓷贴面的边缘特征[J]. 北京大学学报(医学版), 2022, 54(1): 140-145. |

| [4] | 魏菱,邹东,陈虎,潘韶霞,孙玉春,周永胜. 一种数字化全口义齿的临床疗效评价[J]. 北京大学学报(医学版), 2020, 52(4): 762-770. |

| [5] | 王顺吉,章文博,于尧,谢晓艳,杨宏宇,彭歆. 术前虚拟设计在股前外侧皮瓣修复口腔颌面部缺损中的应用[J]. 北京大学学报(医学版), 2020, 52(1): 119-123. |

| [6] | 李欣欣,柳玉树,孙玉春,陈虎,叶红强,周永胜. 计算机辅助设计与制作一体化聚醚醚酮可摘局部义齿不同形态组件的适合性评价[J]. 北京大学学报(医学版), 2019, 51(2): 335-339. |

| [7] | 李峥,柳玉树,叶红强,刘云松,胡文杰,周永胜. 数字化修复结合牙周手术解决复杂前牙美学缺陷[J]. 北京大学学报(医学版), 2017, 49(1): 71-075. |

| [8] | 赵一姣, 王勇, 吕培军. 一种基于数字化牙颌模型的三维咬合分析方法[J]. 北京大学学报(医学版), 2008, 40(1): 109-111. |

|

||