北京大学学报(医学版) ›› 2021, Vol. 53 ›› Issue (2): 402-405. doi: 10.19723/j.issn.1671-167X.2021.02.028

不同刃状边缘补偿角度的两种氧化锆全瓷冠断裂强度的评价

杨欣1,李榕2,叶红强1,陈虎2,王勇2,周永胜1,Δ( ),孙玉春2,Δ(

),孙玉春2,Δ( )

)

- 1.修复科, 北京大学口腔医学院·口腔医院, 国家口腔疾病临床医学研究中心 口腔数字化医疗技术和材料国家工程实验室 口腔数字医学北京市重点实验室, 北京 100081

2.口腔医学数字化研究中心, 北京大学口腔医学院·口腔医院, 国家口腔疾病临床医学研究中心 口腔数字化医疗技术和材料国家工程实验室 口腔数字医学北京市重点实验室, 北京 100081

Evaluation of fracture strength of two kinds of zirconia all-ceramic crowns with different edge compensation angles

YANG Xin1,LI Rong2,YE Hong-qiang1,CHEN Hu2,WANG Yong2,ZHOU Yong-sheng1,Δ( ),SUN Yu-chun2,Δ(

),SUN Yu-chun2,Δ( )

)

- 1. Department of Prosthodontics, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

2. Center for Digital Dentistry, Peking University School and Hospital of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology, Beijing 100081, China

摘要:

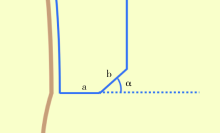

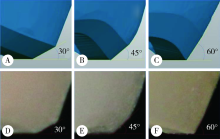

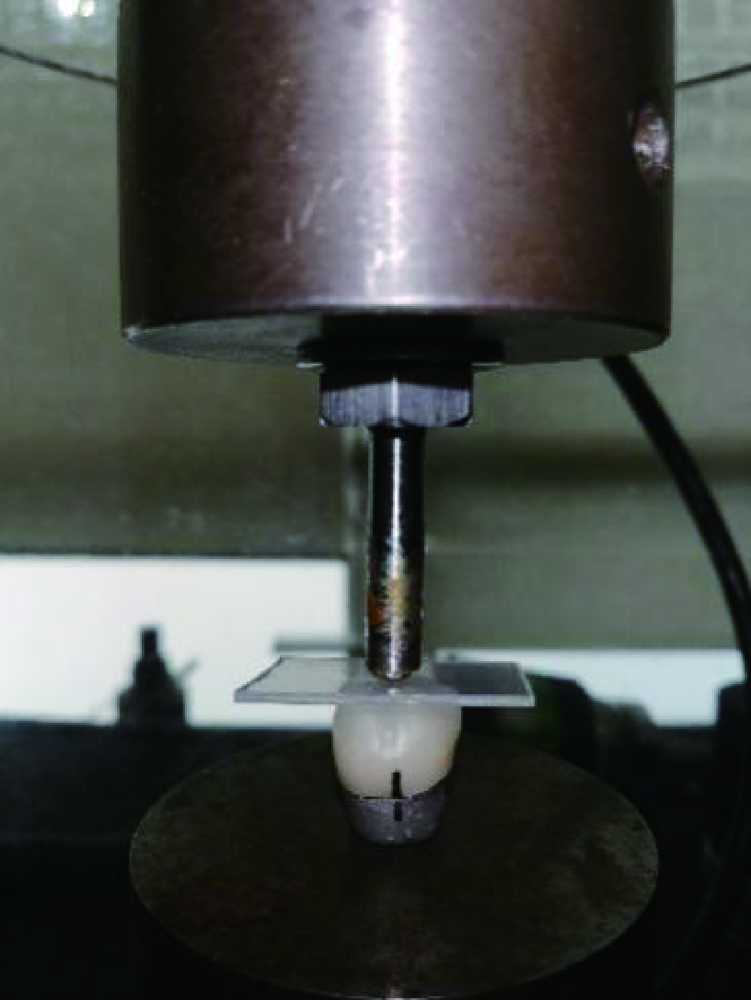

目的: 评价不同刃状边缘补偿角度对多层氧化锆全瓷冠和传统均质氧化锆全瓷冠断裂强度的影响。方法: 制作刃状边缘的下颌第一磨牙树脂牙预备体试件,使用三维牙颌模型扫描仪扫描试件,得到其三维数字模型。将数字模型导入计算机辅助设计(computer aided design, CAD)软件中,设计出牙合面形态相同的三种边缘补偿角度分别为30°、45°、60°的全冠三维数字模型,并将其导入计算机辅助制造(computer aided manufacturing,CAM)软件中,加工出三种不同边缘补偿角度的多层和均质氧化锆全瓷冠各10个,共60个。在电子万能试验机下检测各个牙冠的断裂载荷。结果: 多层和均质氧化锆全瓷冠的平均断裂载荷,30°组分别为 (4 322.86±610.07) N和(5 914.12±596.80) N,45°组分别为(5 264.82±883.76) N和(5 220.83±563.38) N,60°组分别为(4 900.42±345.41) N和(5 050.22±560.24) N,其中30°组中多层氧化锆全瓷冠的断裂载荷明显小于均质氧化锆全瓷冠的断裂载荷(P<0.05), 45°组和60°组中差异均无统计学意义(P>0.05)。在多层氧化锆全瓷冠中,30°组氧化锆全瓷冠的断裂载荷明显低于45°组(P<0.05), 30°组与60°组、45°组与60°组差异无统计学意义(P>0.05)。在均质氧化锆全瓷冠中,30°组高于45°组,30°组高于60°组(P<0.05), 45°组与60°组差异无统计学意义(P>0.05)。结论: 三种不同边缘补偿角度制作的均质和多层氧化锆全瓷冠的断裂载荷均能满足临床要求,在使用传统氧化锆全瓷冠时推荐使用较小的边缘补偿角度,而在使用多层氧化锆全瓷冠时推荐使用的边缘补偿角度为45°。

中图分类号:

- R783.4

| [1] | 张富强. 口腔修复材料氧化锆陶瓷的研究与应用[J]. 上海交通大学学报(医学版), 2006,26(10):1081-1084. |

| [2] | Choi YJ, Razzoog ME. Masking ability of zirconia with and without veneering porcelain[J]. J Prosthet Dent, 2013,22(2):98-104. |

| [3] |

Vichi A, Louca C, Corciolani G, et al. Color related to ceramic and zirconia restorations: A review[J]. Dent Mater, 2011,27(1):97-108.

pmid: 21122905 |

| [4] |

Spies BC, Balmer M, Jung RE, et al. All-ceramic, bi-layered crowns supported by zirconia implants: Three-year results of a prospective multicenter study[J]. J Dent, 2017,67:58-65.

pmid: 28939484 |

| [5] |

Pihlaja J, Näpänkangas R, Raustia A. Outcome of zirconia partial fixed dental prostheses made by predoctoral dental students: A clinical retrospective study after 3 to 7 years of clinical service[J]. J Prosthet Dent, 2016,116(1):40-46.

pmid: 26868964 |

| [6] |

Chai H, Lee JW, Mieleszko AJ, et al. On the interfacial fracture of porcelain/zirconia and graded zirconia dental structures[J]. Acta Biomater, 2014,10(8):3756-3761.

pmid: 24769152 |

| [7] | 冯海兰, 徐军. 口腔修复学[M]. 北京: 北京大学医学出版社, 2013: 71-72. |

| [8] | 孙玉春, 李榕, 周永胜, 等. 三维打印在口腔修复领域中的应用[J]. 中华口腔医学杂志, 2017,52(6):381-385. |

| [9] | 朱黎黎. 不同牙合面厚度及锆材对全解剖式二氧化锆冠抗压强度的影响[D]. 河北:河北医科大学, 2015. |

| [10] | Yin R, Lee MH, Bae TS, et al. Effect of finishing condition on fracture strength of monolithic zirconia crowns[J]. Dent Mater, 2019,38(2):203-210. |

| [11] |

Weigl P, Sander A, Wu Y, et al. In-vitro performance and fracture strength of thin monolithic zirconia crowns[J]. J Adv Prosthodont, 2018,10(2):79-84.

doi: 10.4047/jap.2018.10.2.79 pmid: 29713427 |

| [12] | Nakamura K, Mouhat M, Nergård JM, et al. Effect of cements on fracture resistance of monolithic zirconia crowns[J]. Acta Biomater, 2016,2(1):12-19. |

| [13] |

Zhang Y, Chai H, Lee JW, et al. Chipping resistance of graded zirconia ceramics for dental crowns[J]. J Dent Res, 2012,91(3):311-315.

pmid: 22232142 |

| [14] |

Mitov G, Anastassova-Yoshida Y, Nothdurft FP, et al. Influence of the preparation design and artificial aging on the fracture resistance of monolithic zirconia crowns[J]. J Adv Prosthodont, 2016,8(1):30-36.

pmid: 26949485 |

| [15] |

Comlekoglu M, Dundar M, Ozcan M, et al. Influence of cervical finish line type on the marginal adaptation of zirconia ceramic crowns[J]. Oper Dent, 2009,34(5):586-592.

doi: 10.2341/08-076-L pmid: 19830974 |

| [16] | Beuer F, Aggstaller H, Edelhoff D, et al. Effect of preparation design on the fracture resistance of zirconia crown copings[J]. Dent Mater, 2008,27(3):362-367. |

| [17] |

Poggio CE, Dosoli R, Ercoli C. A retrospective analysis of 102 zirconia single crowns with knife-edge margins[J]. J Prosthet Dent, 2012,107(5):316-321.

doi: 10.1016/S0022-3913(12)60083-3 pmid: 22546309 |

| [18] |

Gibbs CH, Anusavice KJ, Young HM, et al. Maximum clenching force of patients with moderate loss of posterior tooth support: A pilot study[J]. J Prosthet Dent, 2002,88(5):498-502.

doi: 10.1067/mpr.2002.129062 pmid: 12473999 |

| [1] | 孙玉春,郭雨晴,陈虎,邓珂慧,李伟伟. 口腔精准仿生修复技术的自主创新研发与转化[J]. 北京大学学报(医学版), 2022, 54(1): 7-12. |

| [2] | 李文锦,丁茜,原福松,孙丰博,郑剑桥,鲍蕊,张磊. 飞秒激光表面处理对氧化锆表面特征及弯曲强度的影响[J]. 北京大学学报(医学版), 2021, 53(4): 770-775. |

| [3] | 尹祯敏,王子轩,陈俊锴,孙玉春,刘云松,叶红强,周永胜. 可摘局部义齿适合性方法的评价[J]. 北京大学学报(医学版), 2021, 53(2): 406-412. |

| [4] | 李思雨,段雪飞,曹烨. 应用超声器械改善预备体肩台的效果[J]. 北京大学学报(医学版), 2021, 53(1): 88-94. |

| [5] | 国丹妮,潘韶霞,衡墨笛,屈健,魏秀霞,周永胜. 应用于无牙颌种植修复设计的三维面部扫描配准方法的对比[J]. 北京大学学报(医学版), 2021, 53(1): 83-87. |

| [6] | 李峥,柳玉树,王时敏,张瑞,贾璐,叶红强,胡文杰,赵文艳,刘云松,周永胜. 数字化方法复制暂时修复体牙合面形态在重度磨耗病例中的应用[J]. 北京大学学报(医学版), 2021, 53(1): 62-68. |

| [7] | 罗佳,张宇,崔宏燕,祝宁,沈惠丹,邸萍,林野. 锥度固位结合数字化技术在后牙连续多牙种植即刻修复中的应用[J]. 北京大学学报(医学版), 2020, 52(5): 964-970. |

| [8] | 王皓,刘洋,刘浩辰,韩冬,冯海兰. 先天性缺牙患者中BMP2基因突变检测及功能分析[J]. 北京大学学报(医学版), 2019, 51(1): 9-15. |

| [9] | 刘潇倩,陈秋雯,冯海兰,王兵,屈健,孙振,衡墨迪,潘韶霞. 无牙颌患者locator附着体种植覆盖义齿修复后口腔卫生维护的纵向研究[J]. 北京大学学报(医学版), 2019, 51(1): 136-144. |

| [10] | 朱晓鸣,齐璇,李德利,张玉玮,李和平,谭建国. 不同温度新型大气压冷等离子体处理对牙本质粘接强度的影响[J]. 北京大学学报(医学版), 2019, 51(1): 43-48. |

| [11] | 柴金友,刘建彰,王兵,屈健,孙振,高文慧,郭天晧,冯海兰,潘韶霞. 一种切削法制作的数字化种植手术导板加工精度评价[J]. 北京大学学报(医学版), 2018, 50(5): 892-898. |

| [12] | 李世赢,李刚,冯海兰,潘韶霞. 锥形束CT分析下颌无牙颌患者前部颌弓形态对“All-on-4”种植设计的影响[J]. 北京大学学报(医学版), 2017, 49(4): 699-703. |

| [13] | 李熠,徐莉,周彦恒,欧阳翔英,曹甜. 牙周正畸牙体联合治疗1例预后无望上前牙患者的长期疗效观察#br#[J]. 北京大学学报(医学版), 2017, 49(4): 740-744. |

| [14] | 何慧莹,刘洋,韩冬,刘浩辰,白保晶,冯海兰. 先天性牙齿缺失患者EDA基因突变检测及其表现型分析[J]. 北京大学学报(医学版), 2016, 48(4): 686-691. |

| [15] | 王莺, 林野, 陈波, 张宇, 邸萍. 即刻种植术后牙槽突骨板改建及美学效果评价[J]. 北京大学学报(医学版), 2016, 48(1): 121-125. |

|

||