北京大学学报(医学版) ›› 2025, Vol. 57 ›› Issue (6): 1165-1173. doi: 10.19723/j.issn.1671-167X.2025.06.022

多孔表面结构对立体光固化成型氧化锆疲劳强度的影响

赵健霄1, 丁茜1, 李文锦1, 马全诠1, 兰一笑2, 张磊1,*( ), 韩建民2,*(

), 韩建民2,*( )

)

- 1. 北京大学口腔医学院·口腔医院修复科,北京 100081

2. 北京大学口腔医学院·口腔医院材料研究室,国家口腔医学中心,国家口腔疾病临床医学研究中心,口腔生物材料和数字诊疗装备国家工程研究中心,国家药品监督管理局口腔材料重点实验室,北京 100081

Effect of porous surface structure on fatigue strength of 3D printed zirconia

Jianxiao ZHAO1, Qian DING1, Wenjin LI1, Quanquan MA1, Yixiao LAN2, Lei ZHANG1,*( ), Jianmin HAN2,*(

), Jianmin HAN2,*( )

)

- 1. Department of Prosthodontics, Peking University School and Hospital of Stomatology, Beijing 100081, China

2. Department of Dental Materials, Peking University School and Hospital of Stomatology & National Center for Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Research Center of Oral Biomaterials and Digital Medical Devices & NMPA Key Laboratory for Dental Materials, Beijing 100081, China

摘要:

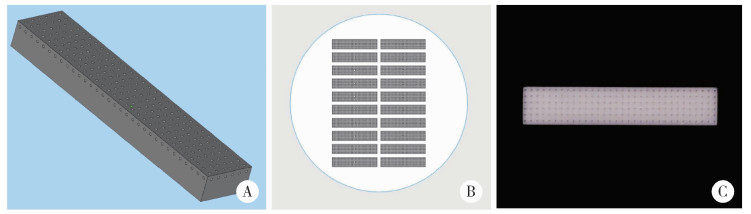

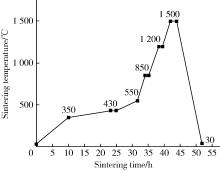

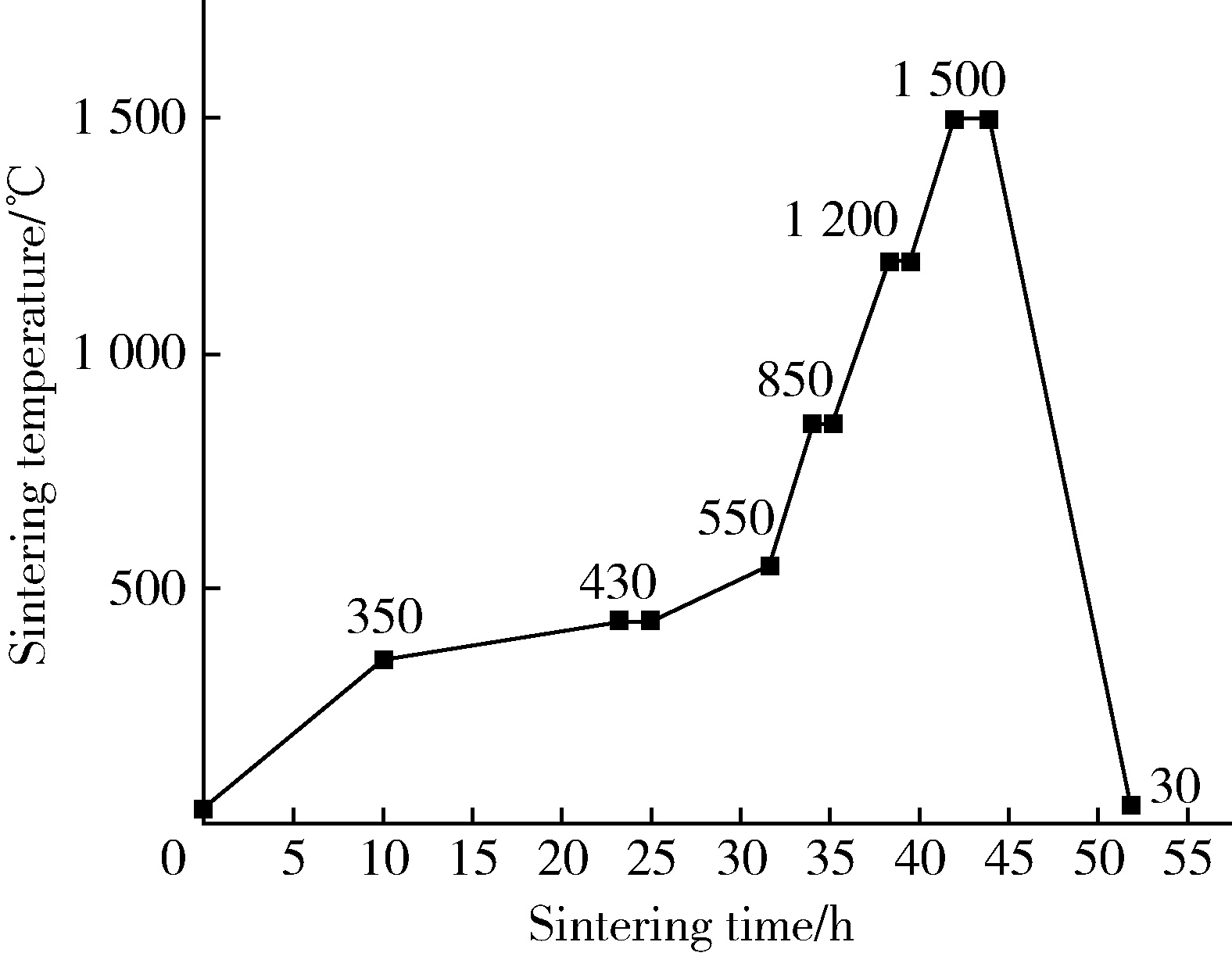

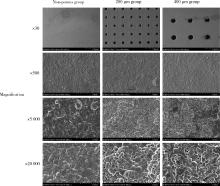

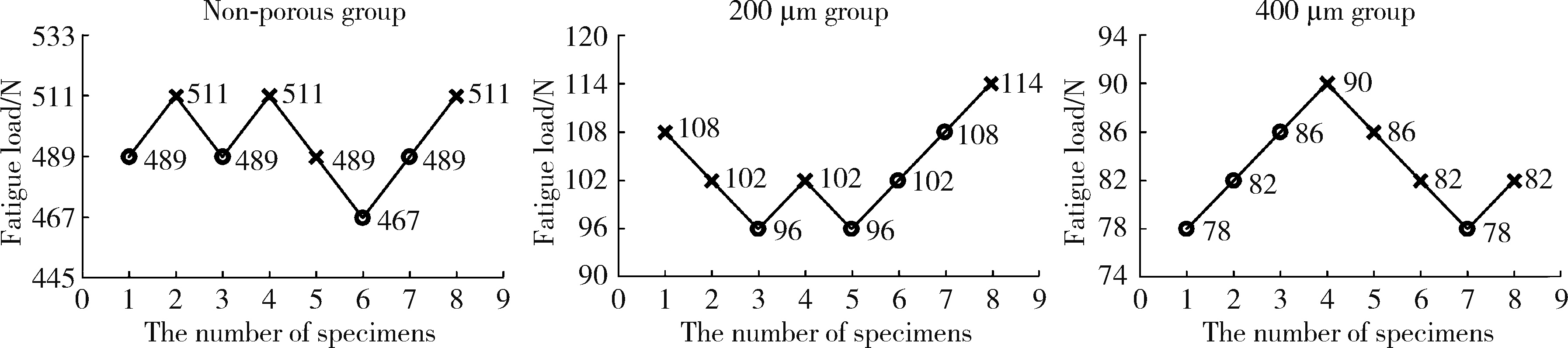

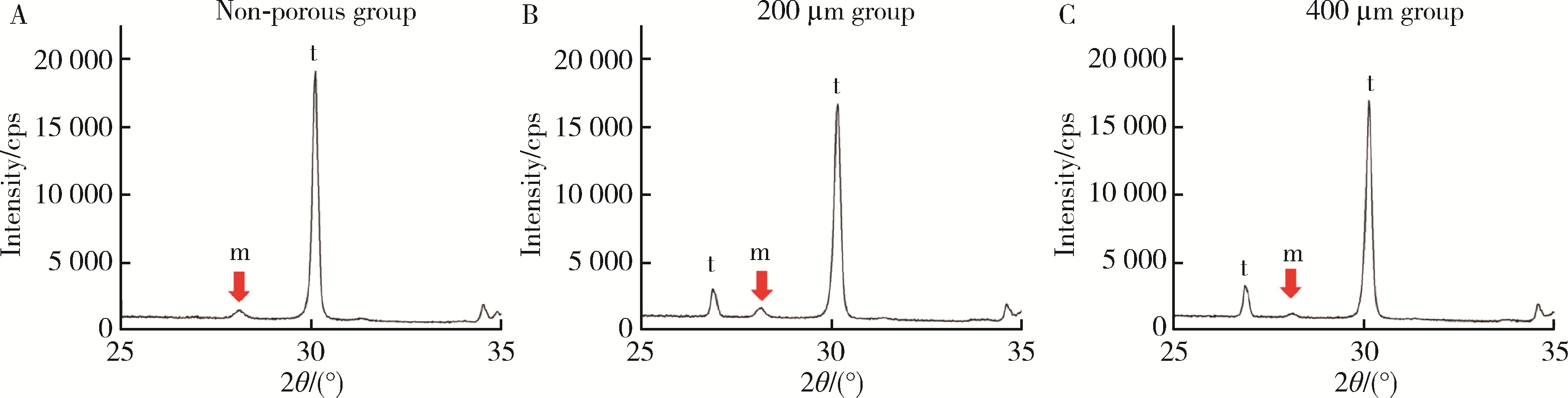

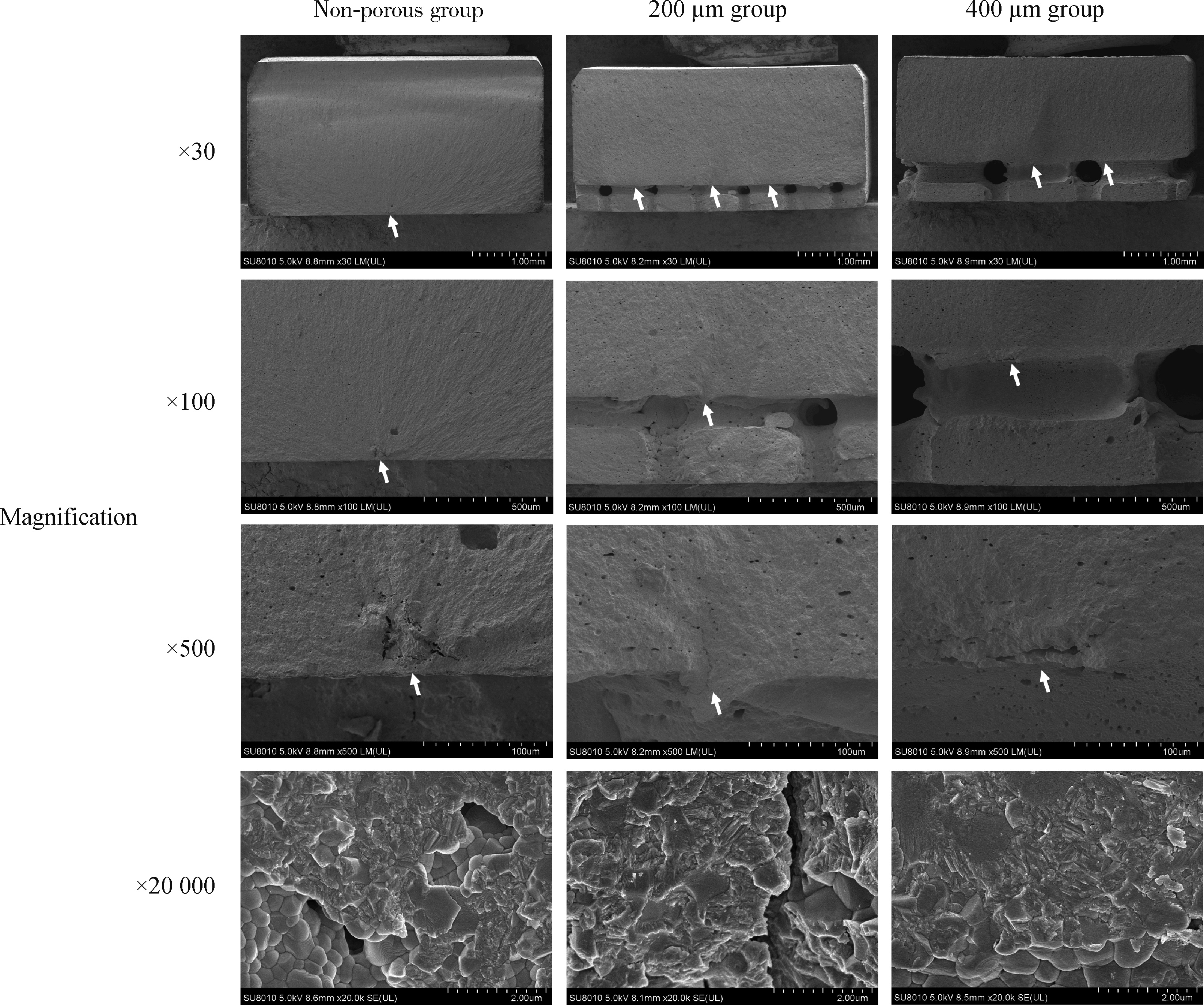

目的: 研究多孔表面结构对立体光固化成型氧化锆疲劳强度的影响,为3D打印氧化锆种植体表面优化设计提供参考。方法: 通过立体光固化成型技术制备氧化锆试件,根据表面结构分为无孔组、200 μm孔组、400 μm孔组。通过三维激光形貌显微镜及扫描电镜观察其表面微观形貌,测定表面粗糙度、孔隙参数、晶粒尺寸。通过三点弯曲试验检测试件弯曲强度,并进行Weibull分析;通过疲劳试验检测试件的疲劳强度,扫描电镜观察断口,采用X射线衍射仪对疲劳试验前后的试件进行晶相分析,分析疲劳机制。结果: 立体光固化成型无孔组、200 μm孔组及400 μm孔组试件表面孔间粗糙度分别为(0.79±0.09) μm、(0.81±0.16) μm、(0.81±0.09) μm,组间差异无统计学意义;表面晶粒尺寸分别为(324.11±21.38) nm、(308.06±11.34) nm、(311.62±15.02) nm,组间差异无统计学意义。三点弯曲试验结果显示,无孔组三点弯曲强度[(1 030.70±111.71) MPa]显著高于两组多孔组(P<0.001),200 μm孔组[(272.04±61.16) MPa]显著高于400 μm孔组[(201.21±25.58) MPa],P<0.01。疲劳试验结果显示,无孔组疲劳强度[(702.29±21.62) MPa]显著高于两组多孔组(P<0.001),200 μm孔组[(159.57±9.30) MPa]显著高于400 μm孔组[(125.36±6.11) MPa],P<0.001。断口分析结果显示,疲劳裂纹源主要为材料内部缺陷、气孔、夹杂及打印层结合处等。疲劳试验前后各组试件之间相比,氧化锆单斜相含量差异均无统计学意义。结论: 表面多孔微观结构会显著降低立体光固化成型氧化锆试件的疲劳强度,且孔径增大可造成疲劳强度下降;未来应着重改进3D打印氧化锆的材料及打印工艺,进一步优化表面结构设计,以提升3D打印氧化锆的力学性能。

中图分类号:

- R783.1

| 1 |

赵祯, 代康, 高勃. 3D打印陶瓷技术在口腔医学领域的研究进展[J]. 中国实用口腔科杂志, 2021, 14 (6): 739- 744.

|

| 2 |

doi: 10.1016/j.jmbbm.2017.08.018 |

| 3 |

doi: 10.1016/j.prosdent.2021.05.010 |

| 4 |

doi: 10.1016/j.msec.2021.111950 |

| 5 |

中国国家标准化管理委员会. 金属平均晶粒度测定方法: GB/T 6394—2017[J]. 北京: 中国标准出版社, 2017, 8- 13.

|

| 6 |

|

| 7 |

doi: 10.1016/j.dental.2005.12.008 |

| 8 |

doi: 10.1016/j.jmbbm.2017.06.016 |

| 9 |

doi: 10.1016/j.jmbbm.2018.05.002 |

| 10 |

doi: 10.1016/j.dental.2017.01.018 |

| 11 |

doi: 10.1016/j.prosdent.2021.11.012 |

| 12 |

doi: 10.1016/j.dental.2013.04.003 |

| 13 |

|

| 14 |

|

| 15 |

doi: 10.1016/0142-9612(96)85758-9 |

| 16 |

doi: 10.1088/1748-6041/10/2/025012 |

| 17 |

doi: 10.1088/1758-5082/6/4/045007 |

| 18 |

doi: 10.3390/nano5020656 |

| 19 |

|

| 20 |

doi: 10.4028/www.scientific.net/MSF.660-661.757 |

| 21 |

doi: 10.1016/j.jmbbm.2014.05.013 |

| 22 |

doi: 10.1016/j.dental.2010.10.025 |

| 23 |

doi: 10.1016/j.pmatsci.2020.100736 |

| 24 |

李文利, 周宏志, 刘卫卫, 等. 光固化3D打印陶瓷浆料及流变性研究进展[J]. 材料工程, 2022, 50 (7): 40- 50.

|

| 25 |

|

| 26 |

doi: 10.3390/ma13061317 |

| 27 |

doi: 10.3390/ma15041602 |

| [1] | 钱锟, 刘亦洪. 基于直接法和间接法数字印模制作的高嵌体适合性评价的体外研究[J]. 北京大学学报(医学版), 2025, 57(3): 604-609. |

| [2] | 闵树元, 田耘. 3D打印生物可降解WE43镁合金支架的生物相容性及对骨缺损的治疗[J]. 北京大学学报(医学版), 2025, 57(2): 309-316. |

| [3] | 展新新,曹露露,项东,汤皓,夏丹丹,林红. 成型方向对3D打印口腔义齿基托树脂材料物理性能及力学性能的影响[J]. 北京大学学报(医学版), 2024, 56(2): 345-351. |

| [4] | 胡攀攀,李彦,刘啸,唐彦超,李梓赫,刘忠军. 自稳式人工椎体在颈椎前路手术中的应用[J]. 北京大学学报(医学版), 2024, 56(1): 161-166. |

| [5] | 丁茜,李文锦,孙丰博,谷景华,林元华,张磊. 表面处理对氧化钇和氧化镁稳定的氧化锆种植体晶相及断裂强度的影响[J]. 北京大学学报(医学版), 2023, 55(4): 721-728. |

| [6] | 周华,王仁吉,刘忠军,刘晓光,吴奉梁,党礌,韦峰. 3D打印人工椎体在颈椎脊索瘤全脊椎切除术中的应用[J]. 北京大学学报(医学版), 2023, 55(1): 144-148. |

| [7] | 李伟伟,陈虎,王勇,孙玉春. 氧化锆陶瓷表面硅锂喷涂层的摩擦磨损性能[J]. 北京大学学报(医学版), 2023, 55(1): 94-100. |

| [8] | 开地尔娅·阿不都热合曼,张荣赓,钱浩楠,邹振洋,丹尼娅·叶斯涛,范田园. 个性化剂量熔融沉积成型3D打印茶碱片剂的制备和体外评价[J]. 北京大学学报(医学版), 2022, 54(6): 1202-1207. |

| [9] | 邓艺,张一,李博文,王梅,唐琳,刘玉华. 不同交联剂处理对脱细胞小肠黏膜下层多孔支架的影响[J]. 北京大学学报(医学版), 2022, 54(3): 557-564. |

| [10] | 王铮,丁茜,高远,马全诠,张磊,葛兮源,孙玉春,谢秋菲. 氧化锆多孔表面显微形貌对成骨细胞增殖及分化的影响[J]. 北京大学学报(医学版), 2022, 54(1): 31-39. |

| [11] | 孙玉春,郭雨晴,陈虎,邓珂慧,李伟伟. 口腔精准仿生修复技术的自主创新研发与转化[J]. 北京大学学报(医学版), 2022, 54(1): 7-12. |

| [12] | 李文锦,丁茜,原福松,孙丰博,郑剑桥,鲍蕊,张磊. 飞秒激光表面处理对氧化锆表面特征及弯曲强度的影响[J]. 北京大学学报(医学版), 2021, 53(4): 770-775. |

| [13] | 杨欣,李榕,叶红强,陈虎,王勇,周永胜,孙玉春. 不同刃状边缘补偿角度的两种氧化锆全瓷冠断裂强度的评价[J]. 北京大学学报(医学版), 2021, 53(2): 402-405. |

| [14] | 郑苗,詹凌璐,刘志强,李和平,谭建国. 不同等离子体处理氧化锆对人牙龈成纤维细胞黏附能力的影响[J]. 北京大学学报(医学版), 2019, 51(2): 315-320. |

| [15] | 周团锋,王新知. 计算机辅助设计与制作的一体化氧化锆全瓷桩核5年临床观察[J]. 北京大学学报(医学版), 2018, 50(4): 680-684. |

|

||