北京大学学报(医学版) ›› 2022, Vol. 54 ›› Issue (1): 105-112. doi: 10.19723/j.issn.1671-167X.2022.01.017

选择性激光熔化打印可摘局部义齿圆环形卡环固位力的有限元分析

马珂楠1,2,陈虎2,沈妍汝2,周永胜3,王勇2,孙玉春1,2,△( )

)

- 1.北京大学医学部医学技术研究院,北京 100191

2.北京大学口腔医学院·口腔医院 口腔医学数字化研究中心,口腔修复教研室,北京 100081

3.北京大学口腔医学院·口腔医院 口腔修复科,国家口腔医学中心,国家口腔疾病临床医学研究中心,口腔数字化医疗技术和材料国家工程实验室,口腔数字医学北京市重点实验室,国家卫生健康委员会口腔医学计算机应用工程技术研究中心,国家药品监督管理局口腔材料重点实验室,北京 100081

Finite element analyses of retention of removable partial denture circumferential clasps manufactured by selective laser melting

MA Ke-nan1,2,CHEN Hu2,SHEN Yan-ru2,ZHOU Yong-sheng3,WANG Yong2,SUN Yu-chun1,2,△( )

)

- 1. Institute of Medical Technology, Peking University Health Science Center, Beijing 100191

2. Center of Digital Dentistry, Faculty of Prosthodontics, Peking University School and Hospital of Stomatology, Beijing 100081, China

3. Department of Prosthodontics, Peking University School and Hospital of Stomatology & National Center of Stomatology & National Clinical Research Center for Oral Diseases & National Engineering Laboratory for Digital and Material Technology of Stomatology & Beijing Key Laboratory of Digital Stomatology & NHC Research Center of Engineering and Technology for Computerized Dentistry & NMPA Key Laboratory for Dental Materials, Beijing 100081, China

摘要:

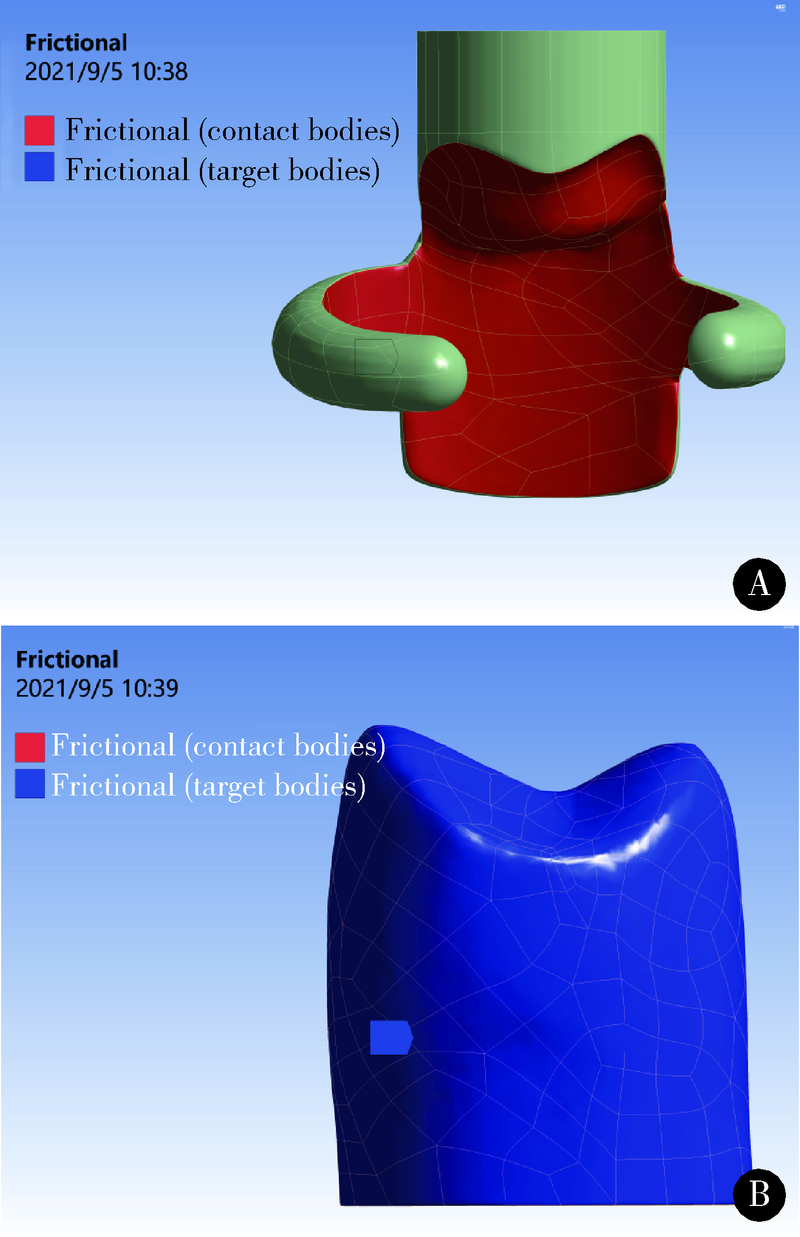

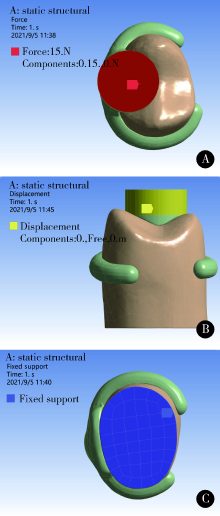

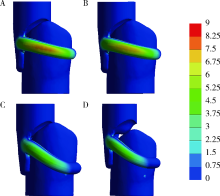

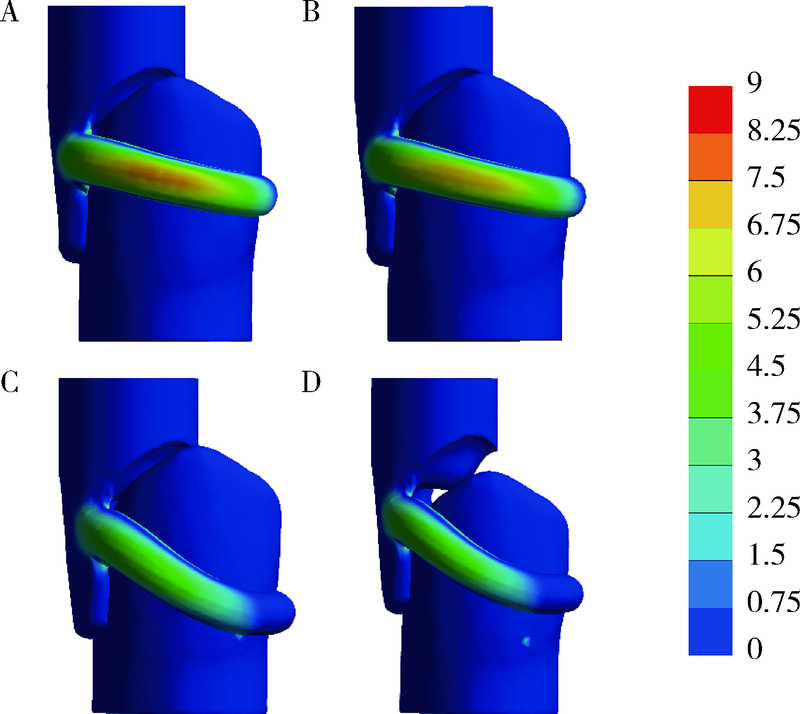

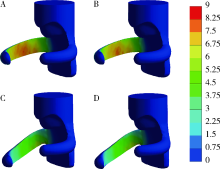

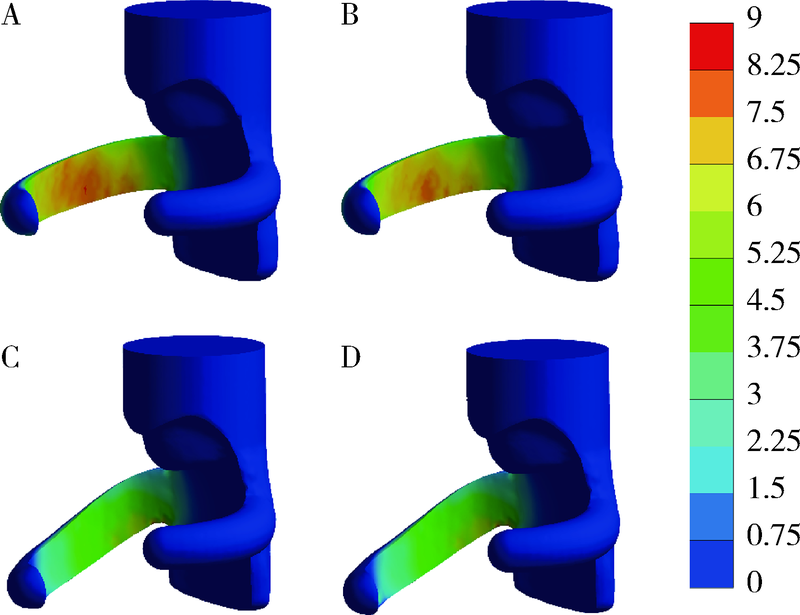

目的: 通过有限元分析对比评价不同设计的选择性激光熔化(selective laser melting, SLM)打印钴铬、纯钛、钛合金(Ti-6Al-4V)可摘局部义齿圆环形卡环的固位力,并分析卡环在脱位过程中的应力分布。方法: 设计A(体部宽度/厚度为1.9 mm/1.1 mm,卡环臂聚合度为0.8)和B (尺寸A的1.2倍)两种圆环形卡环尺寸,再针对上述尺寸分别设计进入0.25 mm(A1,B1)和0.50 mm(A2,B2)两种倒凹深度,建立上述4种形态的卡环和基牙的有限元模型,将测量得到的SLM金属(钴铬、纯钛、钛合金)的密度和弹性模量赋予卡环,将釉质的密度、弹性模量、泊松(Poisson)比赋予基牙。设置卡环臂尺寸为A且进入0.25 mm倒凹的铸造钴铬合金卡环为对照组(C), 并在有限元模型中赋予铸造钴铬合金的密度和弹性模量。所有金属的泊松比设定为0.33。在有限元模型中,沿脱位方向对卡环施加5 N的初始载荷, 计算卡环沿脱位方向的最大位移,若卡环没有完全脱位,则每次在卡环上重新施加比上一次多5 N的载荷,直至卡环能够完全脱位,从而得出不同组卡环的固位力区间。经过上述有限元模型测试,筛选出与对照组卡环固位力区间相同的SLM金属卡环,进一步进行实体的就位/脱位实验验证,并通过有限元分析其von Mises应力分布。结果: 有限元分析发现B1、B2形态的SLM金属(钴铬、纯钛、钛合金)卡环,A2形态的SLM钴铬卡环的固位力均大于对照组卡环。A1形态的SLM纯钛和钛合金卡环的固位力小于对照组卡环。A1形态的SLM钴铬卡环、A2形态的SLM纯钛和钛合金卡环的固位力与对照组卡环相当(15~20 N), 进一步的实体测试表明,这3组SLM金属卡环固位力分别为(21.57±5.41) N、(19.75±4.47) N、(19.32±2.04) N,差异无统计学意义(P>0.05),这3组卡环中,除SLM钛合金卡环外,SLM钴铬和纯钛卡环的最大von Mises应力均超过各自的屈服强度。结论: 对于SLM工艺加工制作的卡环,卡环臂尺寸和进入倒凹深度均相同的钴铬卡环的固位力大于纯钛和钛合金卡环,可通过调整进入倒凹深度和卡环臂尺寸来调整SLM金属卡环的固位力。考虑到义齿在患者口内的长期稳定使用,如采用SLM工艺加工卡环,建议设计卡环臂尺寸为A,进入倒凹量为0.50 mm,并采用钛合金材料制作。

中图分类号:

- R783

| [1] |

Chen H, Li H, Zhao Y, et al. Adaptation of removable partial denture frameworks fabricated by selective laser melting[J]. J Prosthet Dent, 2019, 122(3):316-324.

doi: S0022-3913(18)31162-4 pmid: 30922559 |

| [2] |

Soltanzadeh P, Suprono MS, Kattadiyil MT, et al. An in vitro investigation of accuracy and fit of conventional and CAD/CAM removable partial denture frameworks[J]. J Prosthodont, 2019, 28(5):547-555.

doi: 10.1111/jopr.12997 pmid: 30407685 |

| [3] |

Tasaka A, Shimizu T, Kato Y, et al. Accuracy of removable partial denture framework fabricated by casting with a 3D printed pattern and selective laser sintering[J]. J Prosthodont Res, 2020, 64(2):224-230.

doi: 10.1016/j.jpor.2019.07.009 |

| [4] | 刘一帆, 王伟娜, 于海, 等. 选择性激光熔覆(SLM)钛合金可摘局部义齿支架的适合性研究[J]. 实用口腔医学杂志, 2017, 33(3):302-305. |

| [5] | 刘一帆, 于海, 王伟娜, 等. 选区激光熔化制作可摘局部义齿钛合金支架成形质量初探[J]. 中华口腔医学杂志, 2017, 52(6):351-354. |

| [6] | Reddy JC, Chintapatla SB, Srikakula NK, et al. Comparison of retention of clasps made of different materials using three-dimensional finite element analysis[J]. J Clin Diagn Res, 2016, 10(5):13-16. |

| [7] |

Xie W, Zheng M, Wang J, et al. The effect of build orientation on the microstructure and properties of selective laser melting Ti-6Al-4V for removable partial denture clasps[J]. J Prosthet Dent, 2020, 123(1):163-172.

doi: 10.1016/j.prosdent.2018.12.007 |

| [8] |

Tribst JPM, de Oliveria Dal Piva AM, Borges ALS, et al. Effect of different materials and undercut on the removal force and stress distribution in circumferential clasps during direct retainer action in removable partial dentures[J]. Dent Mater, 2020, 36(2):179-186.

doi: 10.1016/j.dental.2019.11.022 |

| [9] | ISO 22674: 2016(E), Dentistry-Metallic materials for fixed and removable restorations and appliances[S]. 北京: 中国标准出版社, 2016: 10. |

| [10] | YY/T 1702-2020, 牙科学增材制造口腔固定和活动修复用选区熔化金属材料[S]. 北京: 中国标准出版社, 2020: 7. |

| [11] |

Alsheghri AA, Alageel O, Caron E, et al. An analytical model to design circumferential clasps for laser-sintered removable partial dentures[J]. Dent Mater, 2018, 34(10):1474-1482.

doi: S0109-5641(17)30763-7 pmid: 29937332 |

| [12] |

Mahmoud AAA, Wakabayashi N, Takahashi H. Prediction of permanent deformation in cast clasps for denture prostheses using a validated nonlinear finite element model[J]. Dent Mater, 2007, 23(3):317-324.

pmid: 16545447 |

| [13] |

Mahmoud A. Pre-overloading to extend fatigue life of cast clasps[J]. J Dent Res, 2007, 86(9):868-872.

pmid: 17720857 |

| [14] |

Sato Y, Abe Y, Yuasa Y, et al. Effect of friction coefficient on Akers clasp retention[J]. J Prosthet Dent, 1997, 78(1):22-27.

pmid: 9237142 |

| [15] |

Chen X, Mao B, Zhu Z, et al. A three-dimensional finite element analysis of mechanical function for 4 removable partial denture designs with 3 framework materials: Co-Cr, Ti-6Al-4V alloy and PEEK[J]. Sci Rep, 2019, 9(1):13975.

doi: 10.1038/s41598-019-50363-1 pmid: 31562391 |

| [16] |

Kajima Y, Takaichi A, Nakamoto T, et al. Fatigue strength of Co-Cr-Mo alloy clasps prepared by selective laser melting[J]. J Mech Behav Biomed Mater, 2016, 59:446-458.

doi: S1751-6161(16)30005-4 pmid: 26974490 |

| [17] | Yager S, Ma J, Ozcan H, et al. Mechanical properties and microstructure of removable partial denture clasps manufactured using selective laser melting[J]. Addit Manuf, 2015, 8:117-123. |

| [18] |

Takahashi K, Torri M, Nakata T, et al. Fitness accuracy and retentive forces of additive manufactured titanium clasp[J]. J Prosthodont Res, 2020, 64(4):468-477.

doi: S1883-1958(19)30581-X pmid: 32063534 |

| [19] |

Mourshed B, Qaed N, Al-Shamiri H, et al. The effect of environment (dry and natural saliva) on clasp retention: In vitro study: Part Ⅰ[J]. Eur J Dent, 2017, 11(3):352-356.

doi: 10.4103/ejd.ejd_158_17 pmid: 28932146 |

| [1] | 欧蒙恩,丁云,唐卫峰,周永胜. 基台边缘-牙冠的平台转移结构中粘接剂流动的三维有限元分析[J]. 北京大学学报(医学版), 2023, 55(3): 548-552. |

| [2] | 王鹃,尉华杰,孙井德,邱立新. 预成刚性连接杆用于无牙颌种植即刻印模制取的应用评价[J]. 北京大学学报(医学版), 2022, 54(1): 187-192. |

| [3] | 孙玉春,郭雨晴,陈虎,邓珂慧,李伟伟. 口腔精准仿生修复技术的自主创新研发与转化[J]. 北京大学学报(医学版), 2022, 54(1): 7-12. |

| [4] | 李智,徐永祥,包旭东,王晓燕. 垫底树脂和固位深度对树脂基纳米陶瓷髓腔固位冠修复磨牙抗折性能的影响[J]. 北京大学学报(医学版), 2022, 54(1): 95-99. |

| [5] | 任爽,时会娟,张家豪,刘振龙,邵嘉艺,朱敬先,胡晓青,黄红拾,敖英芳. 前交叉韧带重建术后移植物应力的有限元分析[J]. 北京大学学报(医学版), 2021, 53(5): 865-870. |

| [6] | 周伟,安金刚,荣起国,张益. 下颌骨颏部骨折联合双侧髁突囊内骨折致伤机制的三维有限元分析[J]. 北京大学学报(医学版), 2021, 53(5): 983-989. |

| [7] | 姜又升,冯琳,高学军. 垫底材料弹性模量对髓腔固位冠修复后上颌前磨牙应力分布的影响[J]. 北京大学学报(医学版), 2021, 53(4): 764-769. |

| [8] | 罗佳,张宇,崔宏燕,祝宁,沈惠丹,邸萍,林野. 锥度固位结合数字化技术在后牙连续多牙种植即刻修复中的应用[J]. 北京大学学报(医学版), 2020, 52(5): 964-970. |

| [9] | 林春平,卢松鹤,朱浚鑫,胡洪成,岳兆国,唐志辉. 个性化根形种植体的螺纹形态对周围牙槽骨应力分布影响的三维有限元分析[J]. 北京大学学报(医学版), 2019, 51(6): 1130-1137. |

| [10] | 付宏宇,王芳芳,侯晓玫. 控制记忆合金丝镍钛根管锉弯曲性能有限元分析模型的构建及力学分析[J]. 北京大学学报(医学版), 2019, 51(1): 131-135. |

| [11] | 柳大为,李晶,郭亮,荣起国,周彦恒. 舌侧矫治器关闭间隙上前牙牙周膜应力变化的三维有限元分析[J]. 北京大学学报(医学版), 2018, 50(1): 141-147. |

| [12] | 刘婧寅,陈飞,葛严军,魏菱,潘韶霞,冯海兰. 选择性激光熔化种植体对早期骨矿化沉积率的影响[J]. 北京大学学报(医学版), 2018, 50(1): 117-122. |

| [13] | 孙丽颖,郭阳,荣起国,田光磊. 舟骨骨折术后康复治疗的有限元分析[J]. 北京大学学报(医学版), 2016, 48(4): 751-封三. |

| [14] | 赵旭, 张磊, 孙健, 杨振宇,谢秋菲. 后牙种植体支持单冠牙合面高度的三维有限元力学分析[J]. 北京大学学报(医学版), 2016, 48(1): 94-100. |

| [15] | 甄敏,胡文杰,荣起国. 上颌中切牙冠根折行冠延长术并桩核冠修复的三维有限元分析[J]. 北京大学学报(医学版), 2015, 47(6): 1015-1021. |

|

||